A high-efficiency clean core removal equipment for hollow turbine blades

A turbine blade and core removal technology, which is applied in the field of turbine blade manufacturing, can solve problems such as polluting the environment of the core removal chamber, and achieve the effects of ensuring automatic continuous operation, accelerating shedding, and enhancing convection exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

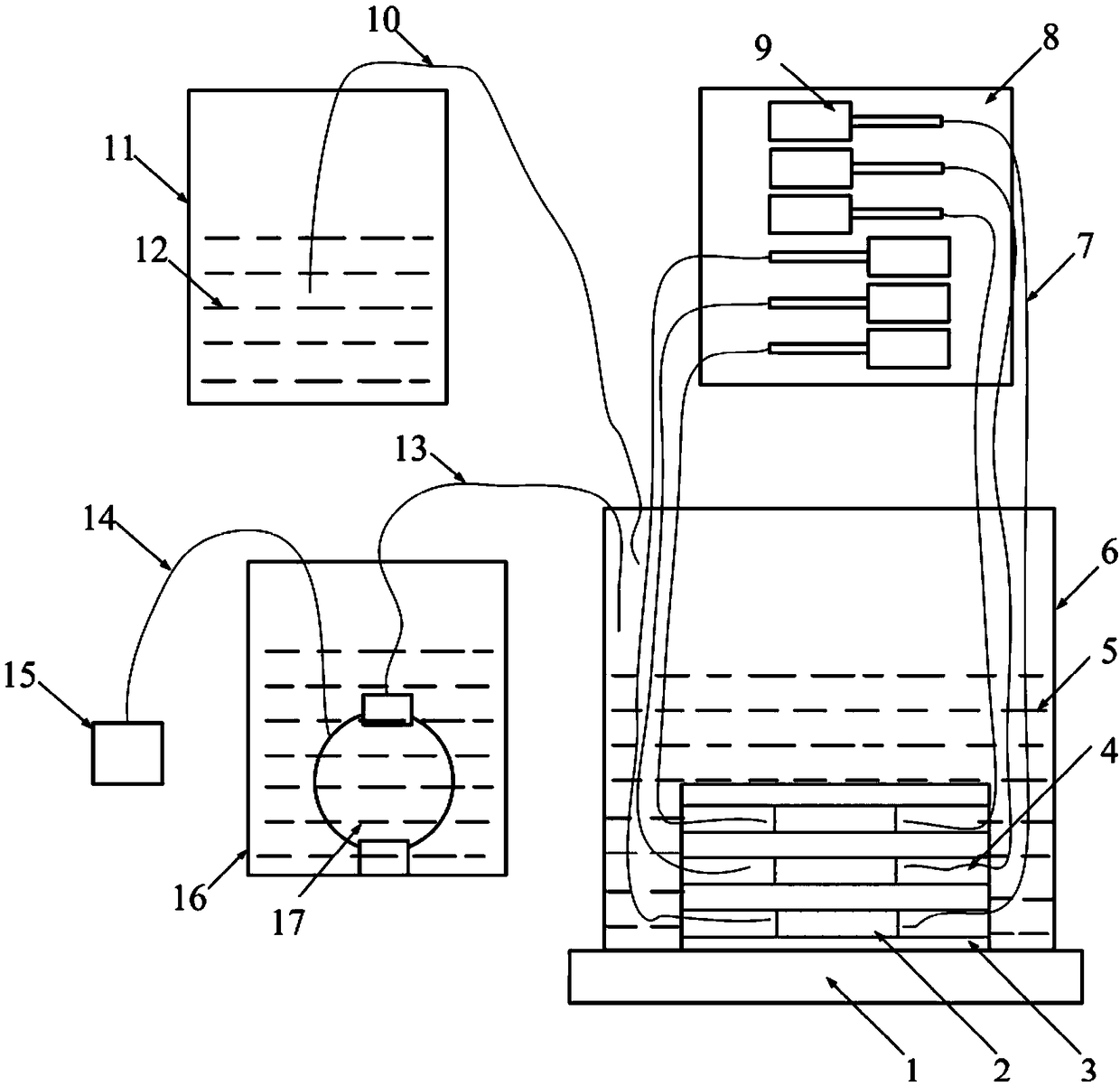

[0035]Firstly, a core removal liquid 5 with an appropriate concentration is prepared in the reaction chamber 6 , and the amount of the core removal liquid 5 is preferably enough to submerge the metal blade 3 . Then reaction chamber 6 is sealed, and each pipeline is connected and sealed well, and the clear water container 16 of automatic water addition in the automatic water adding device and the alkali vapor collection in the alkali vapor recovery device are collected with a sufficient amount of clear water in the clear water container 11, and then Begin to heat up and be heated to lye boiling, and open automatic water-adding device, automatically start water pump 17 and add a certain amount of water by timing delay controller 15 at regular intervals. A small amount of alkali vapor volatilized during the core-removing alkali boiling process and a large amount of alkali vapor volatilized during adding water will be collected by the alkali vapor collection device and dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com