Action sequence controllable four-port two-stage double-acting hydraulic cylinder

A double-acting hydraulic cylinder and action sequence technology, which is applied in the field of two-stage double-acting hydraulic cylinders and four-port two-stage double-acting hydraulic cylinders, can solve the problems that hydraulic cylinders cannot reach the stroke, increase equipment manufacturing costs, and cumbersome on-site vision. , to achieve the effect of reliable action sequence, saving equipment manufacturing cost, and reducing equipment safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

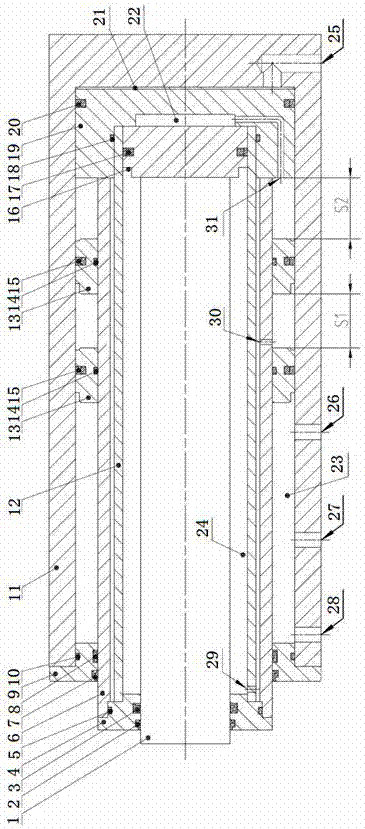

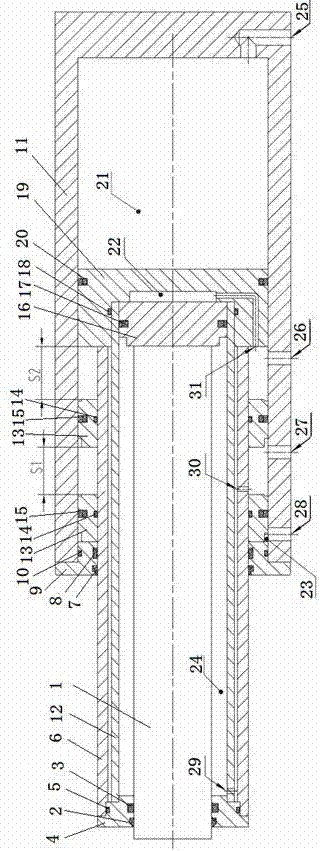

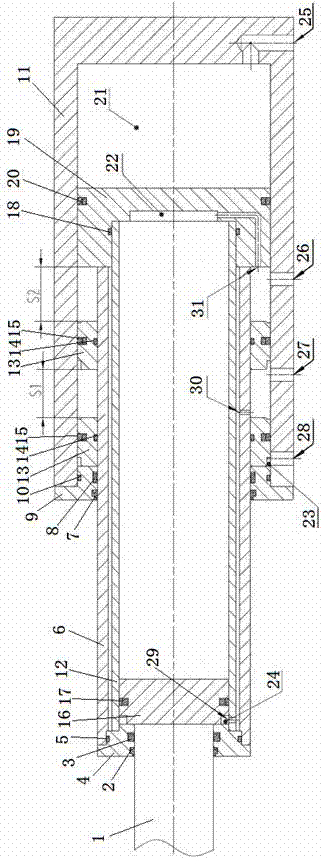

[0013] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The specific embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

Embodiment

[0014] Example: A four-port two-stage double-acting hydraulic cylinder with controllable action sequence (see figure 1 ), which includes a secondary piston rod 1, one end of the secondary piston rod 1 is provided with a secondary front cover 4, the other end of the secondary piston rod 1 is threadedly connected to the secondary piston 16, and the secondary piston 16 is provided with a secondary The cylinder barrel 12 and the secondary cylinder barrel 12 are provided with a primary piston rod 6 and a primary piston 19. The two ends of the primary piston rod 6 are respectively threaded with the secondary front cover 4 and the primary piston 19. A cylinder barrel assembly 11 is provided, the cylinder barrel assembly 11 is threadedly connected to the first-level front cover 9, and two first-level limit pistons 13 are arranged between the cylinder barrel assembly 11 and the first-level piston rod 6, and the first-level limit piston 13 passes through the steel. The ball is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com