Switching device and application method thereof

A conversion device and piston technology, applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of difficulty and trouble in switching to the unlocked state, and achieve the change of assembly characteristics of loose parts, reduced use, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

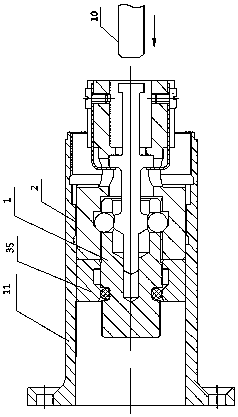

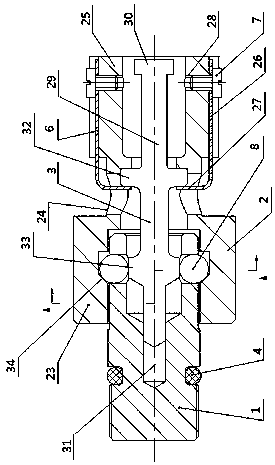

[0033] See figure 1 , the conversion device provided by the embodiment of the present invention includes a piston 1, a first sleeve 2, a pull rod 3 and an elastic limiter 6; the piston 1 and the first sleeve 2 are arranged inside and outside the joint; the The pull rod 3 is movably arranged in the piston 1 and the first sleeve 2; the piston 1, the first sleeve 2 and the pull rod 3 enclose a housing chamber 9, and the ball 8 is arranged in the The first sleeve 2 is respectively provided with elastic stoppers 6 for limiting the axial position of the pull rod 3 on both sides of the pull rod 3 .

[0034] Working principle: the piston 1 is connected with the first sleeve 2 through threads, so as to realize the connection between the gyro mechanism and the acceleration mechanism with a certain pre-tightening force, so that the product is in a locked state. When the rear end face of the pull rod 3 is subjected to the impact force of the striker 10 of the master adjustment platform, ...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 , 2 as well as Figure 4 As shown, the piston 1 is a hollow structure with one end open, which includes a first end face 1 and a second end face 12 oppositely disposed; and an outer face 13 connecting the first end face 1 and the second end face 12 .

[0039] Such as Figure 5 As shown, the first end surface 1 is recessed with a first axial hole 14 toward the direction of the second end surface 12 . The piston 1 has a radial hole 15 recessed inward from its outer surface 13; the radial hole 15 communicates with the first axial hole 14, and a part of the ball 8 is located in the radial hole 15, The pull rod 3 passes through the first axial hole 14 .

[0040] Such as Figure 5 As shown, the first axial hole 14 is composed of a first straight hole 16 , a first tapered hole 17 , a second straight hole 18 and a second tapered hole 19 connected in sequence. The diameter of the first straight hole 16 is larger than the diameter...

Embodiment 3

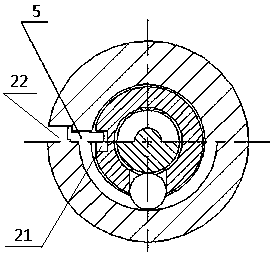

[0043] On the basis of Example 2, such as figure 2 , image 3 As shown, the outer surface 13 of the piston 1 is provided with a limiting groove 21 inwardly recessed near the first end surface 1; the first sleeve 2 is provided with a limiting hole 22 passing through it in the radial direction. The limiting groove 21 is connected with the limiting hole 22 through the first fastener 5 .

[0044] The first fastener 5 is a screw or a pin or the like.

[0045] The present invention connects the piston 1 and the first bushing 2 through the first fastener 5, so that the piston 1 and the first bushing 2 do not rotate relative to each other in the radial direction but follow the movement. Upward produces a limiting effect. On the one hand, the conversion device as a whole moves in the axial direction so that the product enters the locked state; on the other hand, after the product is unlocked after the general adjustment platform is detected, although the piston 1 and the first slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com