Novel dedusting equipment

A dust removal equipment and a new type of technology, applied in the direction of cleaning equipment, cleaning carpets, cleaning floors, etc., can solve the problems of low degree of automation, large size of dust collector, unsuitable for use in production environment, etc., to achieve convenient operation, simple structure, and reduce The effect of equipment input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

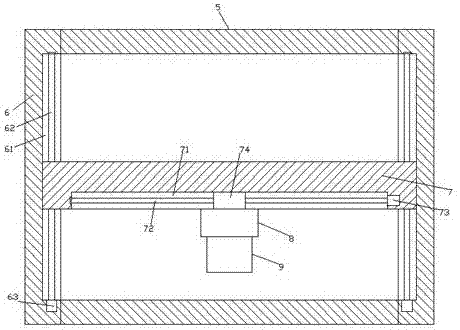

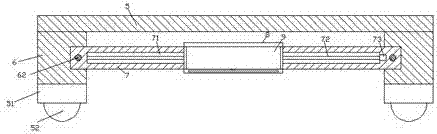

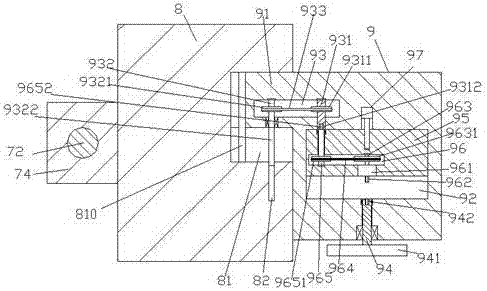

[0022] like Figure 1-Figure 6As shown, a new type of dust removal equipment of the present invention includes a frame body 5, a first sliding rod 6 and a second sliding rod 7, and the front side of the second sliding rod 7 is slidably connected with a sliding member 8 , the front side of the sliding part 8 is provided with a dust removal device 9, the inside of the front side of the sliding part 8 is provided with a first sliding groove 81, and the inside of the first sliding part 81 is provided with a guide extending up and down. Rod 810, the inner bottom of the first sliding groove 81 on the front side of the guide rod 810 is provided with a spiral hole 82 extending downward, and the top boundary of the rear side of the dust removal device 9 is provided with a screw hole 82 extending into the The protrusion 91 in the first sliding groove 81 and is slidingly fitted with the guide rod 810, and the first cavity 92 is provided inside the dust removal device 9, and the first cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com