Heating module and its intelligent electric floor heating

A heating module and electric floor heating technology, applied in the field of intelligent electric floor heating, can solve the problems of affecting comfort and high operating costs, and achieve the effect of overcoming high operating costs and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

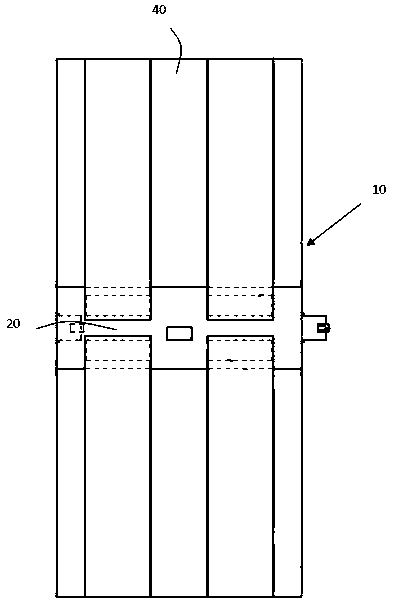

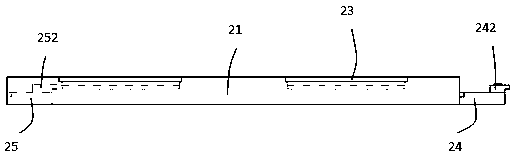

[0042] Such as Figure 1A with 1B As shown, the heating module 10 is composed of a controller unit 20 and a heat conduction unit 40 . Two heat conduction units 40 are symmetrically disposed on two sides of the controller unit 20 . Such as Figure 2A with 2B As shown, the controller unit 20 includes a controller base 21, the upper surface of the controller base 21 has a central concave cavity, and the control block 22 is arranged in the central concave cavity. A carrier communication module, such as a power modem, etc. Side cavities are arranged at intervals on both sides of the central cavity, and a heating block 23 is arranged in each side cavity. A connecting piece 24 protrudes from the bottom of one side of the controller base 21 . The connecting piece 24 has a locking block 242 , and a connecting groove 25 matching the connecting piece 24 is recessed in the bottom of the other side. The connecting slot 25 has a locking hole 252 matched with the locking block 242 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com