Combined chemical storage tank

A combined and chemical technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of transportation inconvenience, cost loss, space occupation, etc., and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

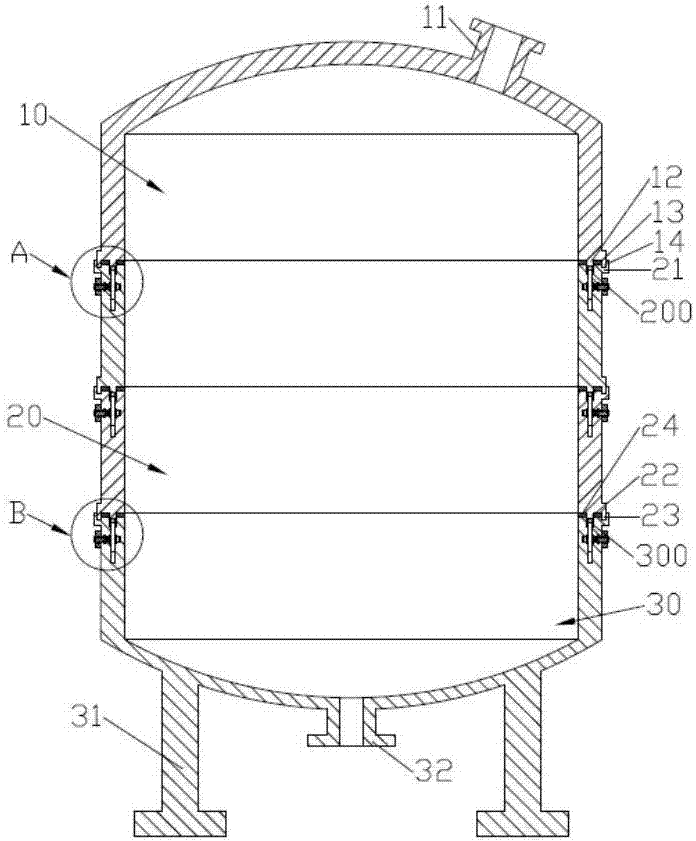

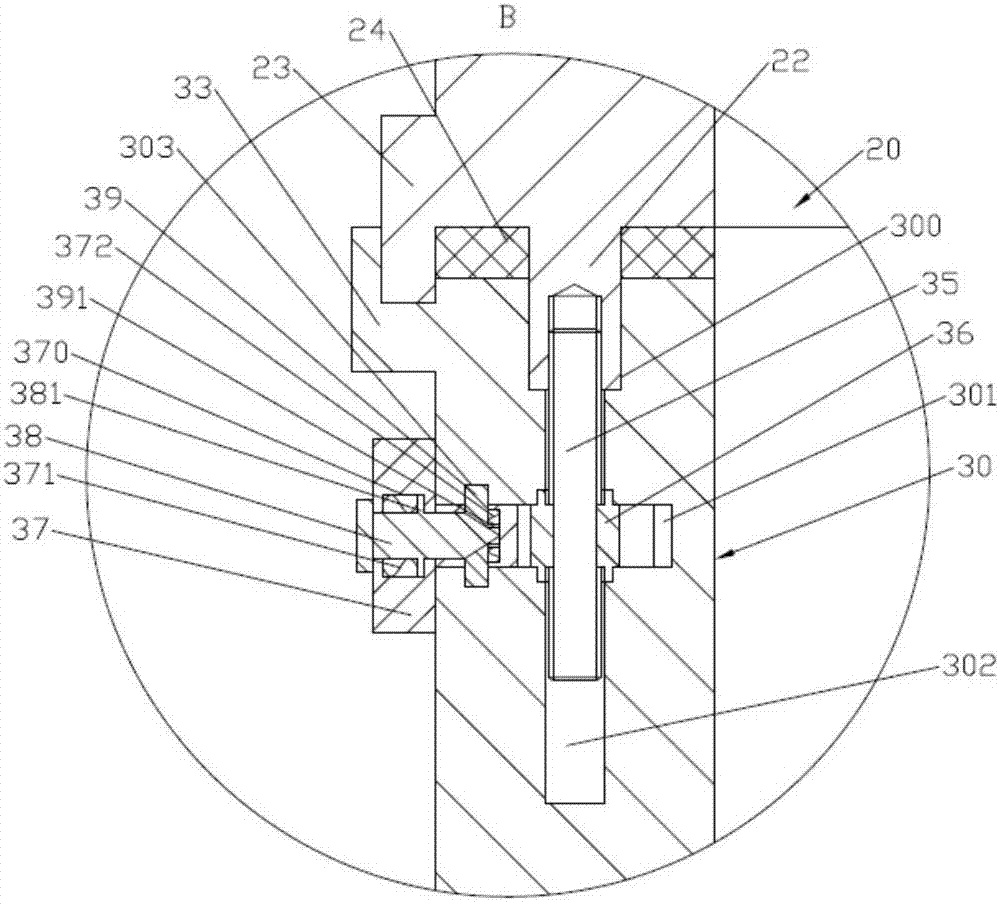

[0018] Such as Figure 1 ~ Figure 3 As shown, a combined chemical storage tank includes an upper cover 10, several middle tank bodies 20 and a lower cover 30; the middle tank body 20 is a ring; some middle tank bodies 20 are distributed from top to bottom; the upper seal The cover 10 is arranged above the uppermost middle tank body 20; the lower cover 30 is arranged below the lowermost middle tank body 20; the top of the upper cover 10 is provided with a feed pipe 11; There is a discharge pipe 32; the bottom of the lower cover 30 is evenly provided with a number of support feet 31; the upper part of the middle tank 20 is provided with an upper connection device; the upper part of the lower cover 30 is provided with a lower connection device; the number of middle tanks 20 at least one.

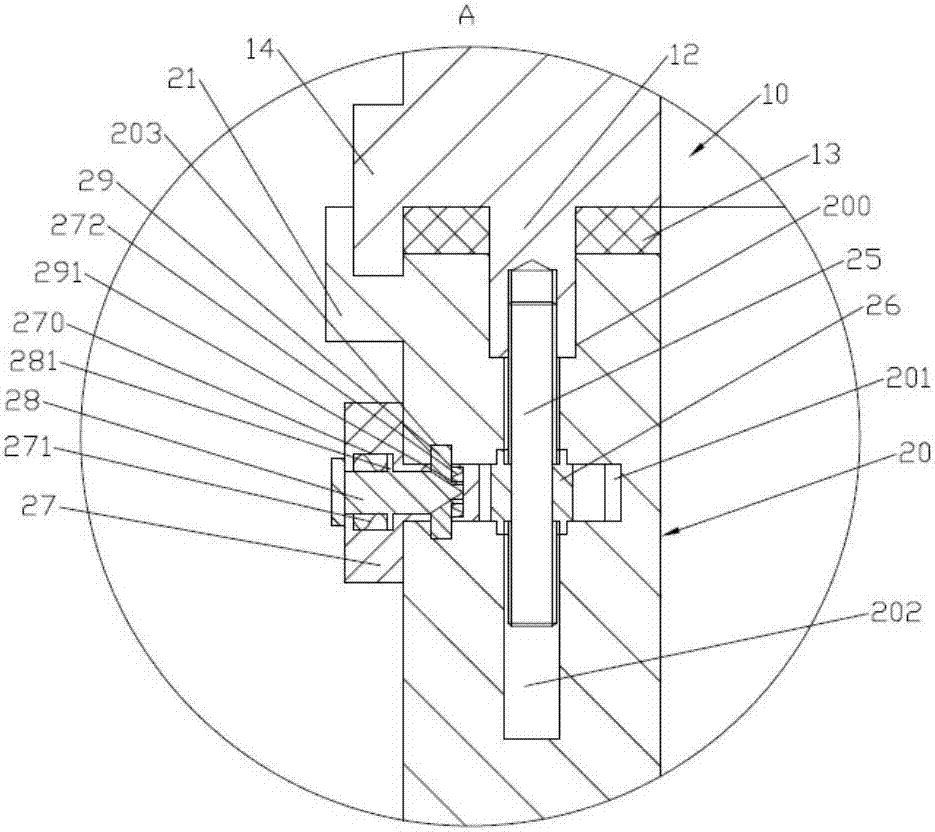

[0019] Such as figure 1 , figure 2 As shown, an annular upper connecting ring 12 is formed on the lower end surface of the upper cover 10; several threaded holes are formed on the lower end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap