Fast Calculation Method of Concrete Curing and Surface Humidity in Complex Environment

A technology for concrete surface and complex environment, which is applied in the field of rapid calculation of surface humidity and concrete maintenance of complex environmental structures. , The effect of strong real-time performance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Quick Calculation Method for Concrete Curing and Surface Humidity in Complicated Environments

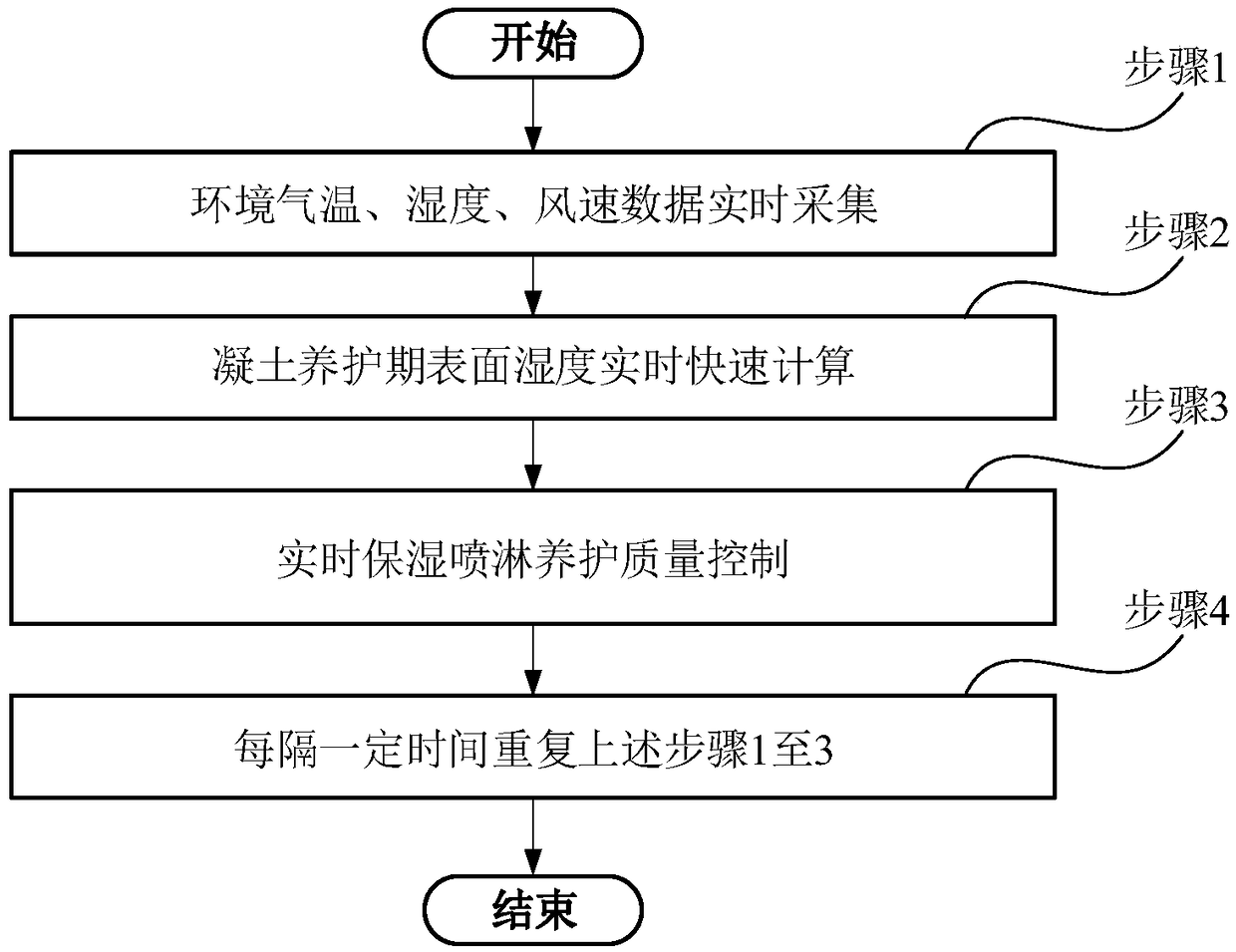

[0040] Such as figure 2 As shown, the complex environment structural concrete maintenance method provided by the first embodiment includes the following steps:

[0041] Step 1. Real-time collection of ambient air temperature, humidity, and wind speed data; in the present embodiment, it is at the concrete curing site, and the construction maintenance personnel (or supervisors when inspecting and supervising) are to measure the ambient air temperature and humidity on the concrete curing surface with a thermo-hygrometer , and the wind speed is taken according to the weather forecast of the day. All measurements shall be kept in construction records.

[0042] Step 2. Real-time and rapid calculation method of surface humidity during the concrete curing period:

[0043] Substitute the data collected in real time in step 1 into formula 1 to calculate the concrete surface humidi...

Embodiment 2

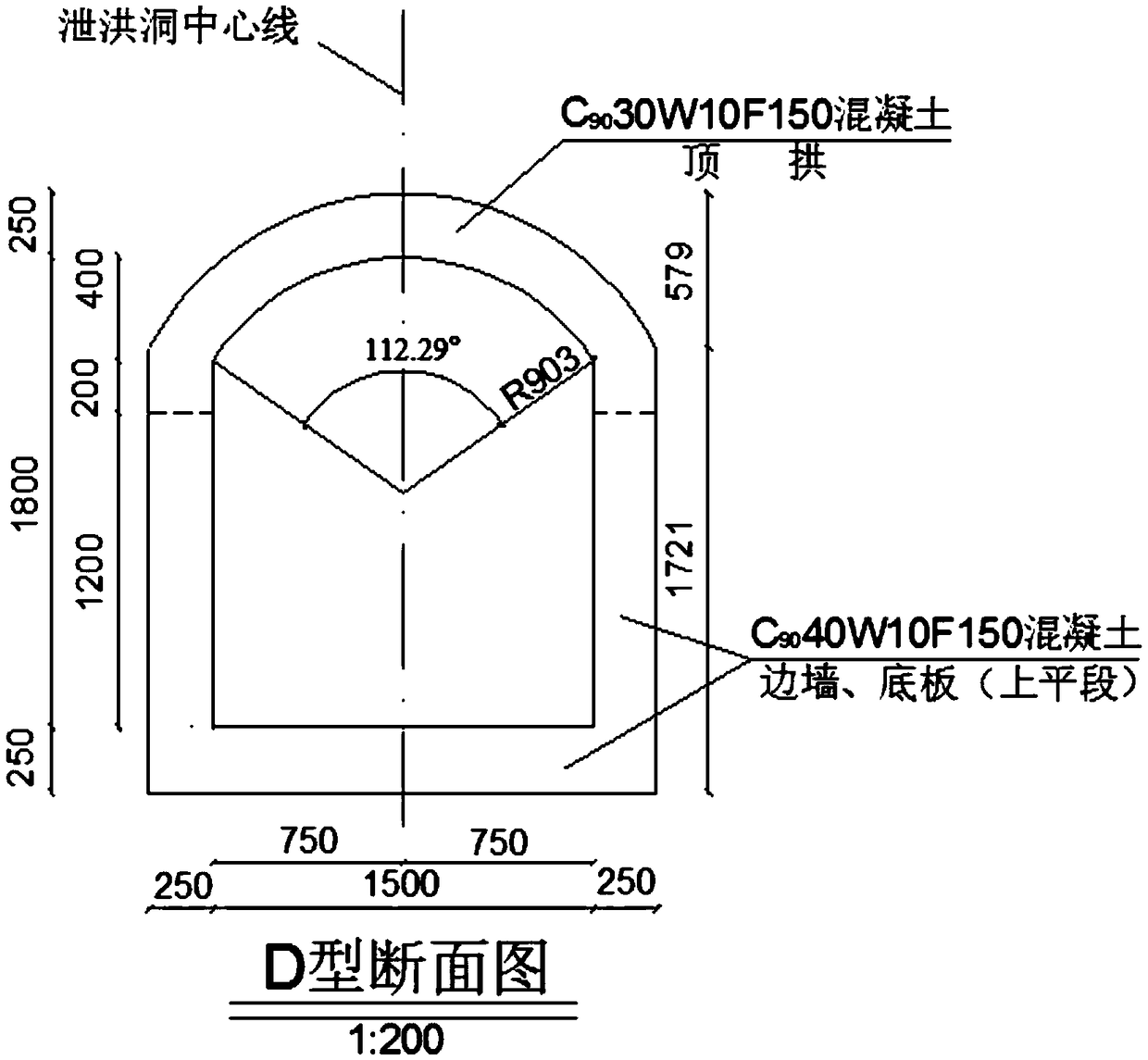

[0050] Real-time control of moisturizing and maintenance quality of lining concrete in the unpressurized section of the flood discharge tunnel of Baihetan Hydropower Station

[0051] (1) Basic information

[0052] The Baihetan Hydropower Station is located in Ningnan County, Sichuan Province, and Qiaojia County, Yunnan Province, on the lower reaches of the Jinsha River. It is a control project for the development and management of the Yangtze River. The installed capacity of the power station is 14,004MW, and the annual average power generation is 60.241 billion kW·h. It is the second largest hydropower station in the world (after the Three Gorges). The hub project is composed of main buildings such as barrage, flood discharge and energy dissipation buildings and water diversion power generation system. The barrage is a concrete hyperbolic arch dam with a maximum height of 289.0m. The flood discharge facilities include 6 surface holes of the dam, 7 deep holes and 3 flood di...

Embodiment 3

[0064] Concrete moisturizing and spraying maintenance of the dam of Baihetan Hydropower Station

[0065] The basic situation of Baihetan Hydropower Station is the same as above. The barrage is a concrete double-curvature arch dam with a crest elevation of 834.00m, a maximum dam height of 289m, a crown beam top width of 14m, a bottom width of 63m, and a maximum arch end thickness of 85.45m. The arc length of the center line of the dam crest is 709m, and it is divided into 31 dam sections. At 24:00 on April 11, 2017, the first warehouse concrete was poured, which is the 18# dam section at the bottom of the dam, with a length of 63m and a width of 24m. Then, the jump warehouse is poured in blocks.

[0066] Dam C 90 30 Low-heat cement concrete is cured with tap water at normal temperature. The maintenance period is 28 days, and the outer surface is maintained until completion.

[0067] (2) Concrete real-time moisturizing and spraying maintenance

[0068] Before the end of J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com