Vibration-resistant electromagnet

A technology of electromagnets and magnetic blocks, which can be used in the direction of electromagnets with armatures, electromagnets, locks operated by non-mechanical transmission, etc., and can solve problems such as poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention, but this does not limit the protection scope of the present invention.

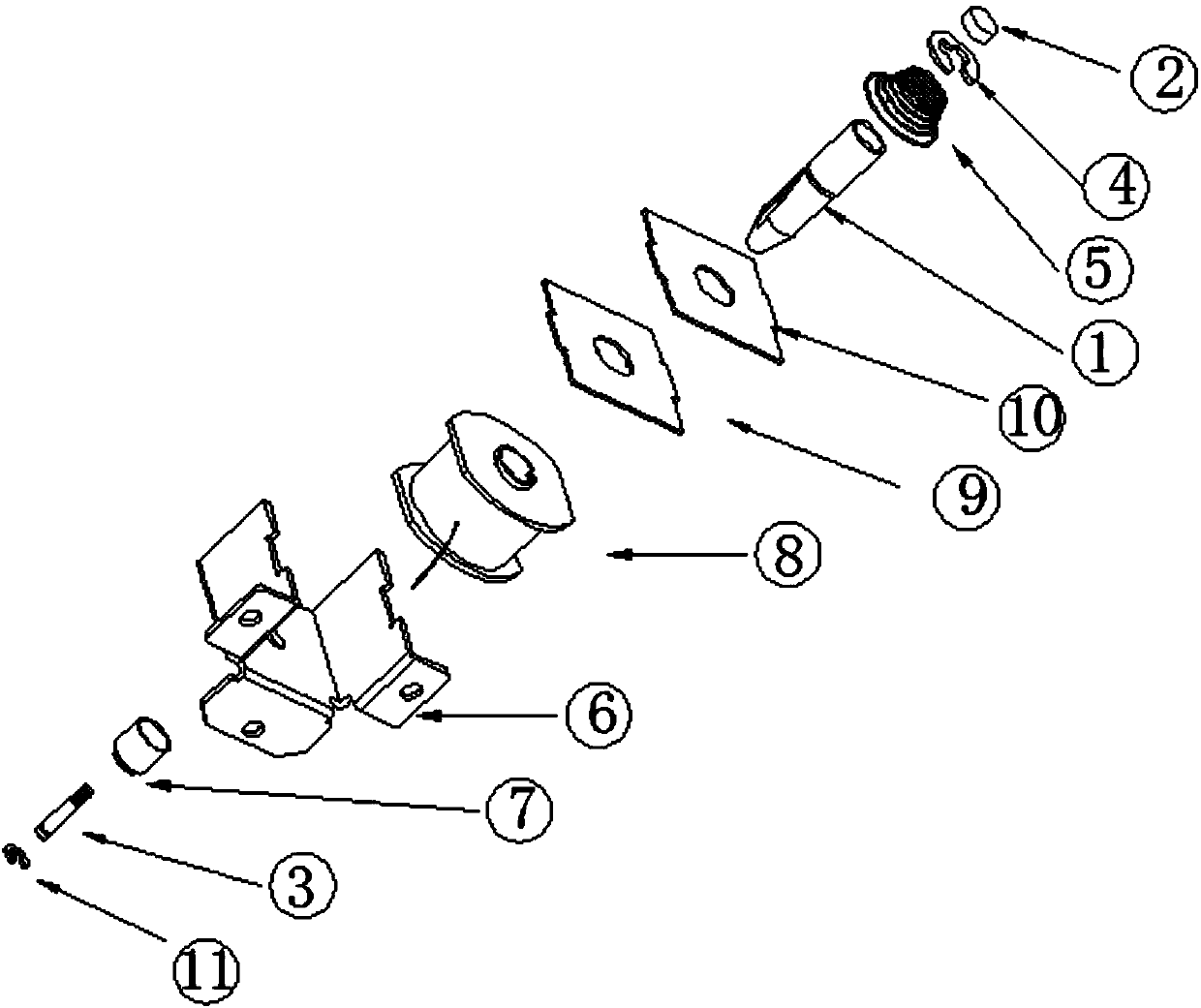

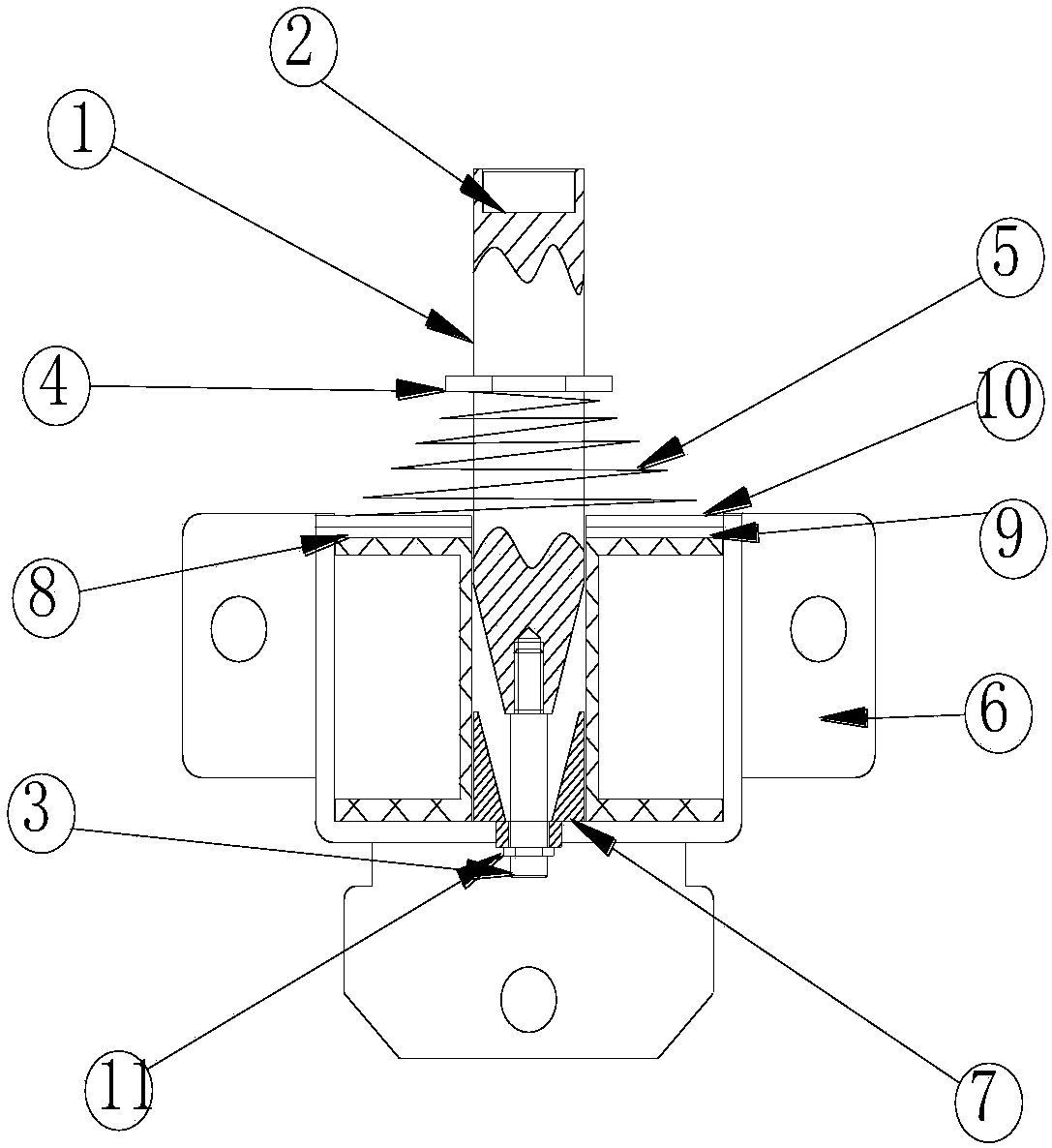

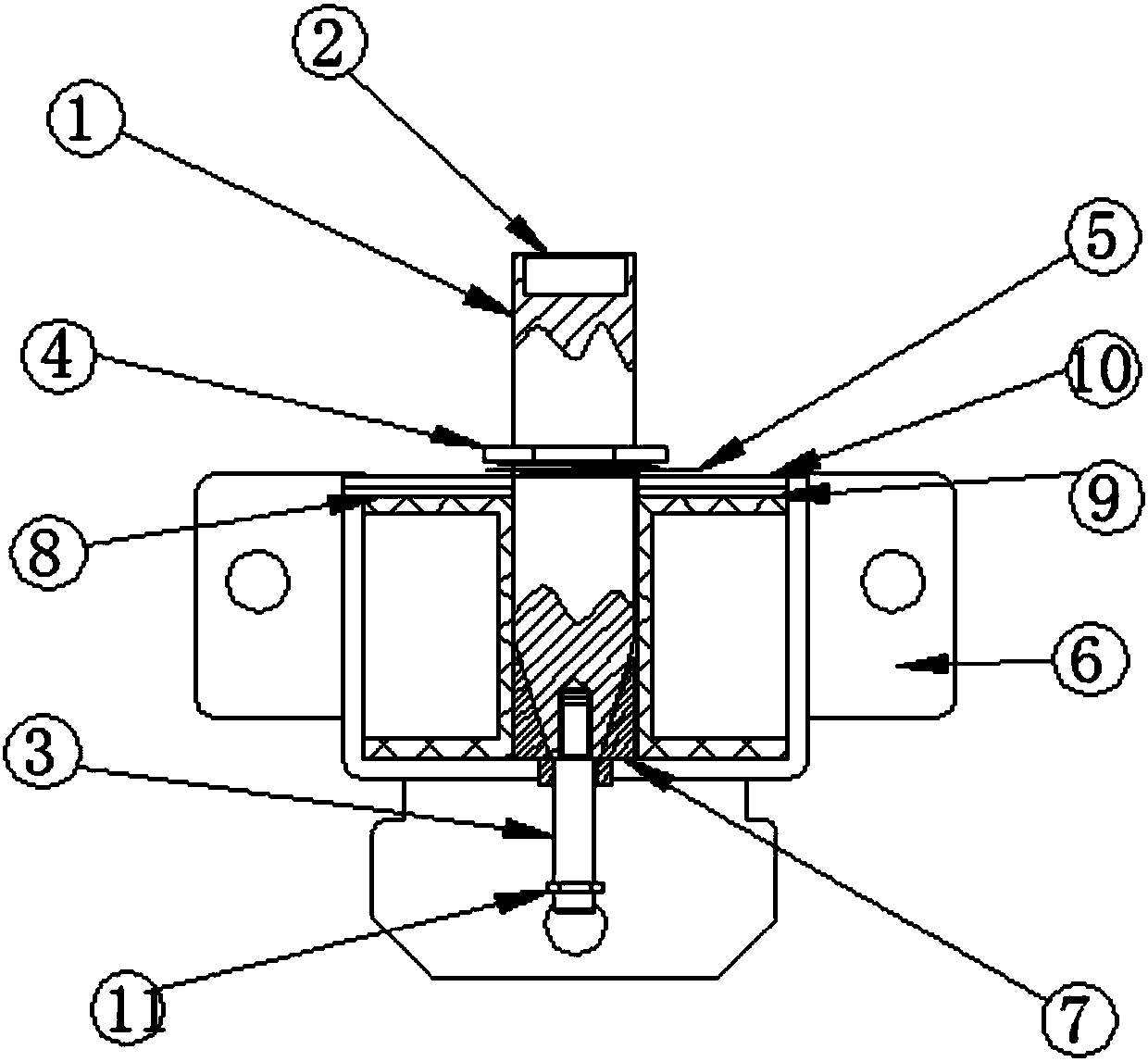

[0014] Such as figure 1 As shown, an anti-vibration electromagnet includes a magnetic block 2, an upper collar 4, a spring 5, a slide rod 1, a first cover plate 10, a second cover plate 9, a coil 8, and a casing 6 connected sequentially from top to bottom. , iron core 7, ejector rod 3, and lower collar 11, wherein the spring 5 and the upper collar 4 are sleeved on the upper part of the slide bar 1, and the magnetic block 2 is installed on the upper end of the slide bar 1, The lower part of the slide bar 1 passes through the first and second cover plates 10, 9 and the coil 8 and is installed in the housing 6 together with the first and second cover plates 10, 9 and the coil 8, The push rod 3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com