Certificate installation device

A technology for installing devices and certificates, applied in the field of assembly equipment, can solve problems such as increased production costs, potential safety hazards, and impacts on production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

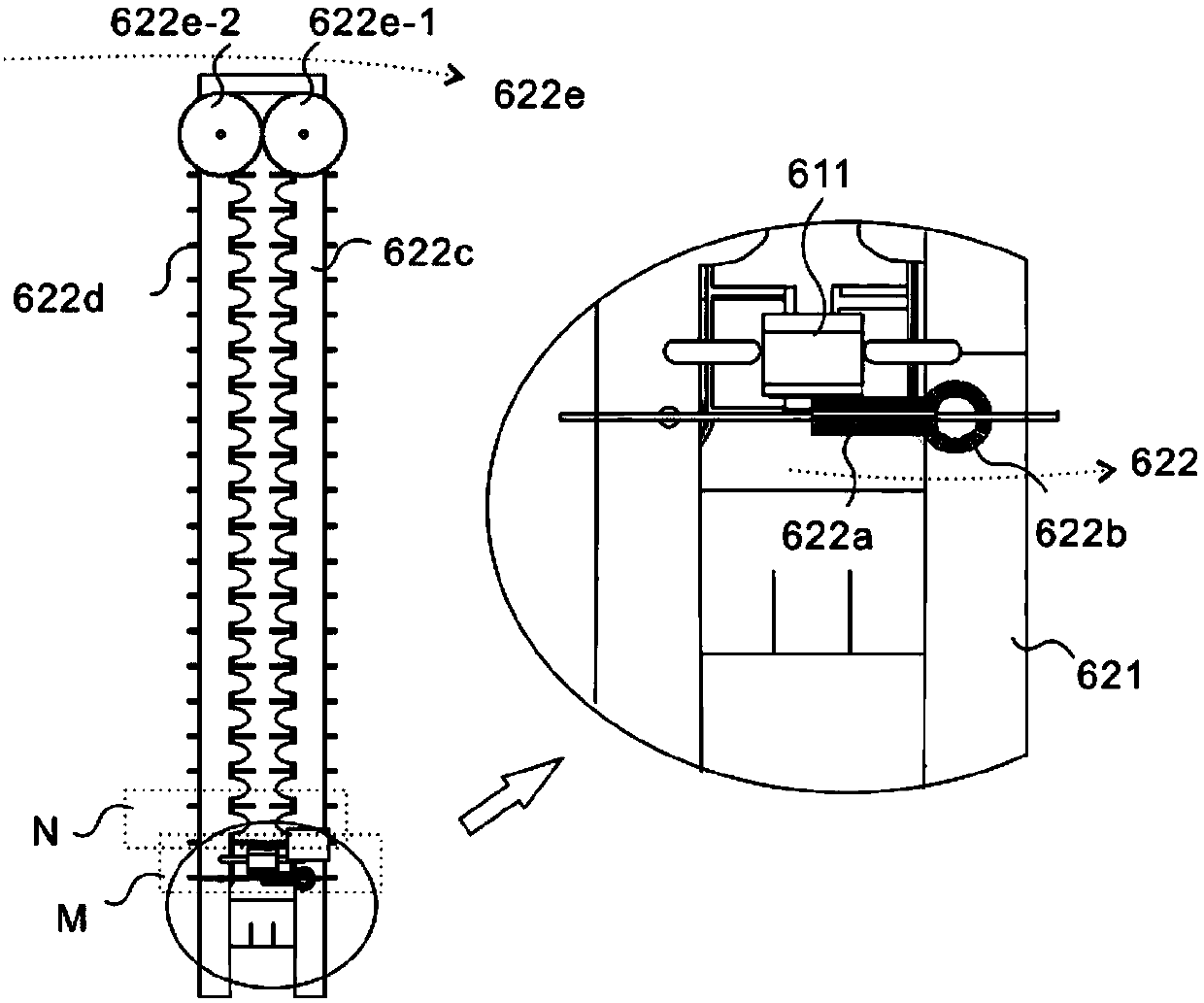

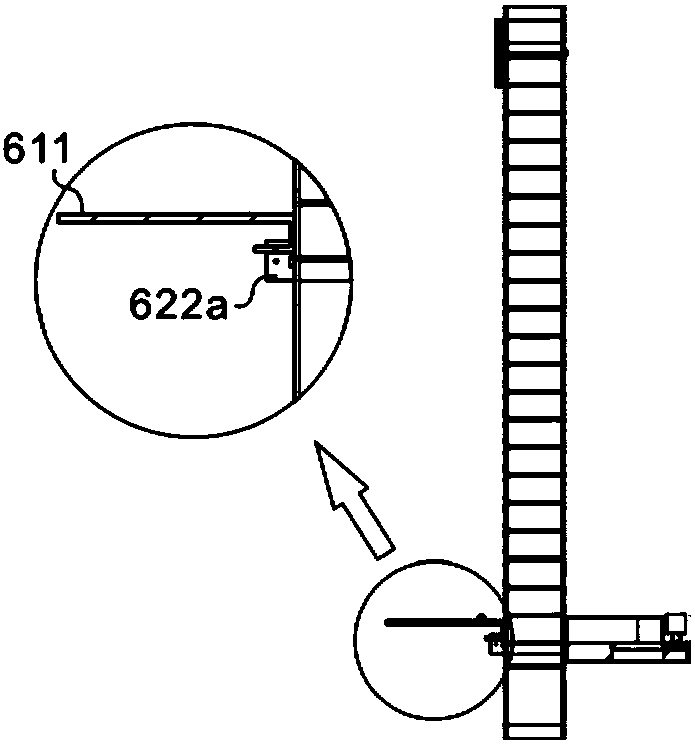

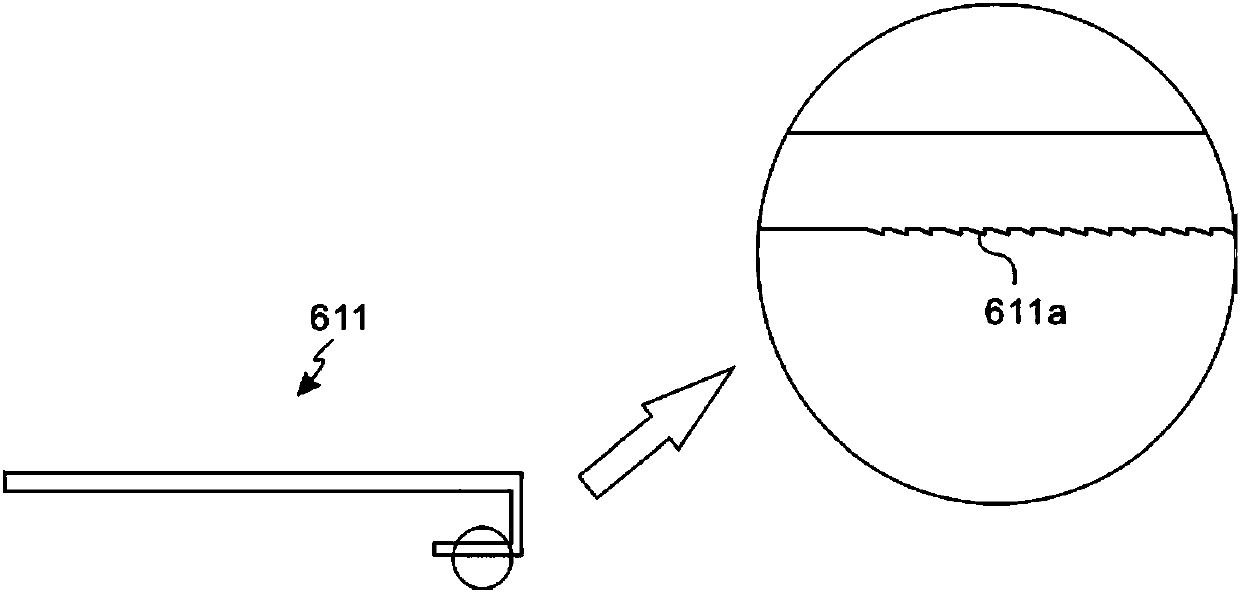

[0029] refer to figure 1 and image 3 , is the second embodiment of the certificate installation device of the present invention. This embodiment is different from the first embodiment in that: the certificate conveyor belt 1401 is provided with a baffle plate 1401a, and the baffle plate 1401a equidistantly places the certificate The conveyor belt 1401 separates independent spaces one by one, and a certificate of conformity is placed in each independent space. This setting is reasonable to avoid placing multiple certificates in one place during the transmission process, because each certificate has its own independent space, when a certificate is placed, it will go to the next independent space, and the certificate in the next space Correspondingly placed in the box at the next position.

[0030] Specifically, the main body of the device includes a third conveying assembly 1400, and the third conveying assembly 1400 includes a certificate conveyor belt 1401 and a certificate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap