Electric power warning bar

A security fence and power technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of damage to the cable insulation, crushing of the security fence, difficult to carry, etc., and achieve the effect of strong anti-hook rolling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

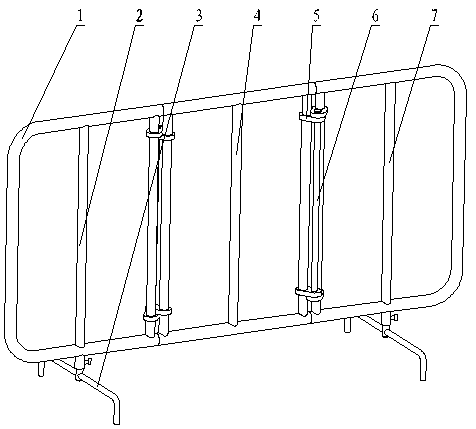

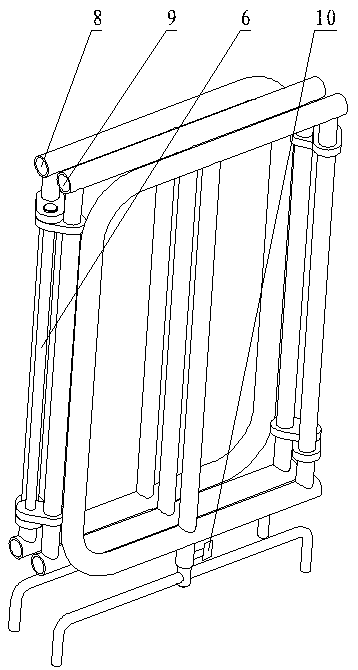

[0019] As shown in the figure, it includes a right side column 2, a middle column 4, and a left side column 7. Between the right side column 2 and the middle column 4, between the middle column 4 and the left side column 7 are hinged to form three Folding guard rail; the upper and lower ends of the right side rail 2 and the left side rail 7 are provided with rounded corners 1, and the upper and lower inner sides of the right side rail 2 and the left side rail 7 are provided with hinge plates 5 in the hinge The bottom of the right column 2 and the left column 7 is provided with a rotary bracket 3; the two sides of the middle column 4 are provided with another hinge plate in the hinge; the hinge plate 5 in the hinge is inserted between the hinge plate and the other hinge plate. Hand 6 forms a hinge part with dual functions of hinge and hand guard, and the hand guard is exposed on both sides of the guardrail after folding.

[0020] The rotary bracket 3 is provided with guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com