The storage compartment partition with a partition part with a hinged sleeve part

A technology for storage compartments and partitions, applied in vehicle parts, interior accessories, transportation and packaging, etc., can solve the problems of not meeting the various needs and applications of vehicle operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

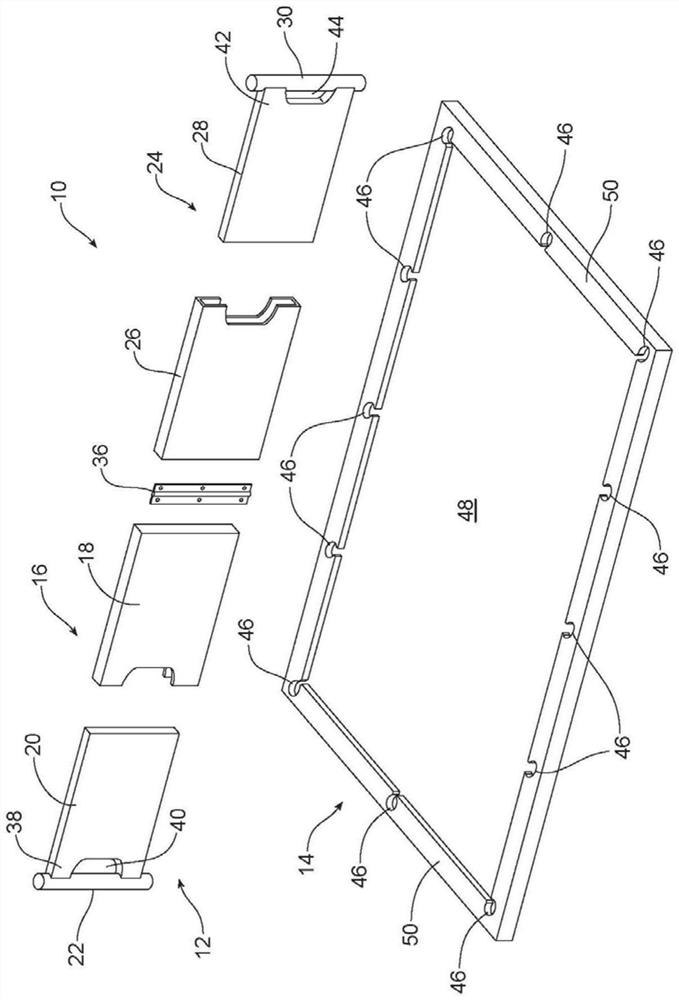

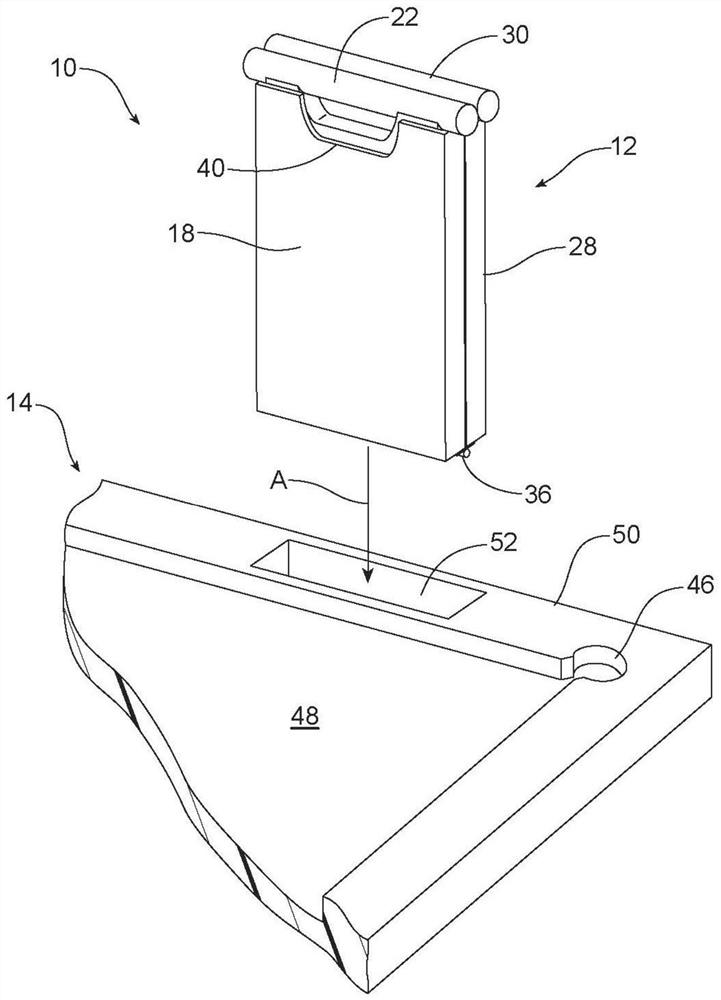

[0020] reference now Figure 1-7 , the storage compartment divider 10 is shown. Storage compartment divider 10 includes a bulkhead, generally designated by reference numeral 12 , and a base, generally designated by reference numeral 14 .

[0021] Separator 12 includes a first portion 16 that includes a first divider panel 18 and a first telescopic extension panel 20 . The first stud 22 is carried on the first telescopic extension plate 20 .

[0022] The bulkhead 12 also includes a second portion 24 that includes a second divider panel 26 and a second telescopic extension panel 28 . The second stud 30 is carried on the second telescopic extension plate.

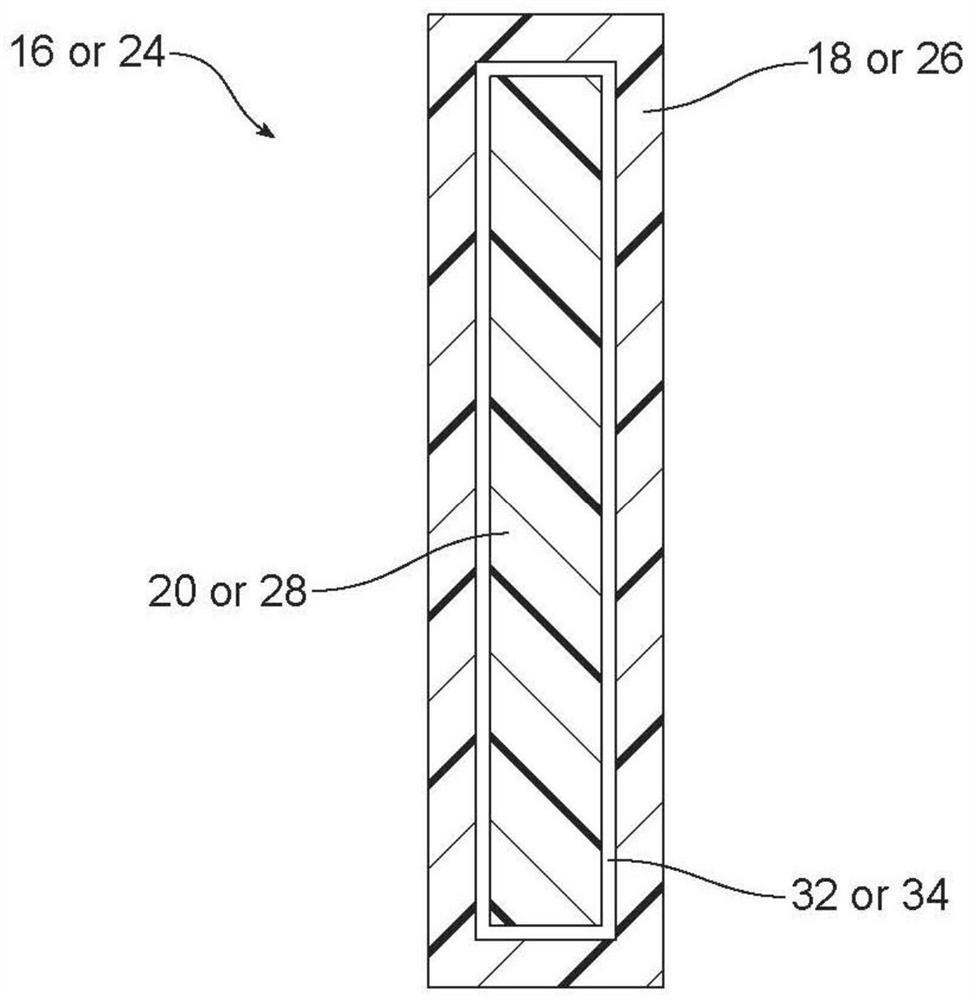

[0023] like figure 2 As best shown, the first divider plate 18 includes a first groove 32 . The first telescopic extension plate 20 is received and slid in the first groove 32 to allow adjustment of the overall length of the first portion 16 of the bulkhead 12 . continue as figure 2 As shown, the second divider plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com