Gear arrangement

A technology for configuring components and gears, which is applied to transmission parts, components with teeth, belts/chains/gears, etc., can solve problems such as disturbing noise, improve tooth wear, reduce noise generation, and simplify manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] As an introduction, it should first be stated that in the various embodiments described differently, the same reference numerals or the same component names are assigned to the same components, wherein the disclosure content contained in the entire description can be used according to the meaning to the same part provided with the same reference number or the same component name. Furthermore, the orientation instructions selected in the specification, such as up, down, sideways, etc., are relative to the direct description and shown drawings, and when the orientation changes, they can be transferred to the new orientation according to the meaning.

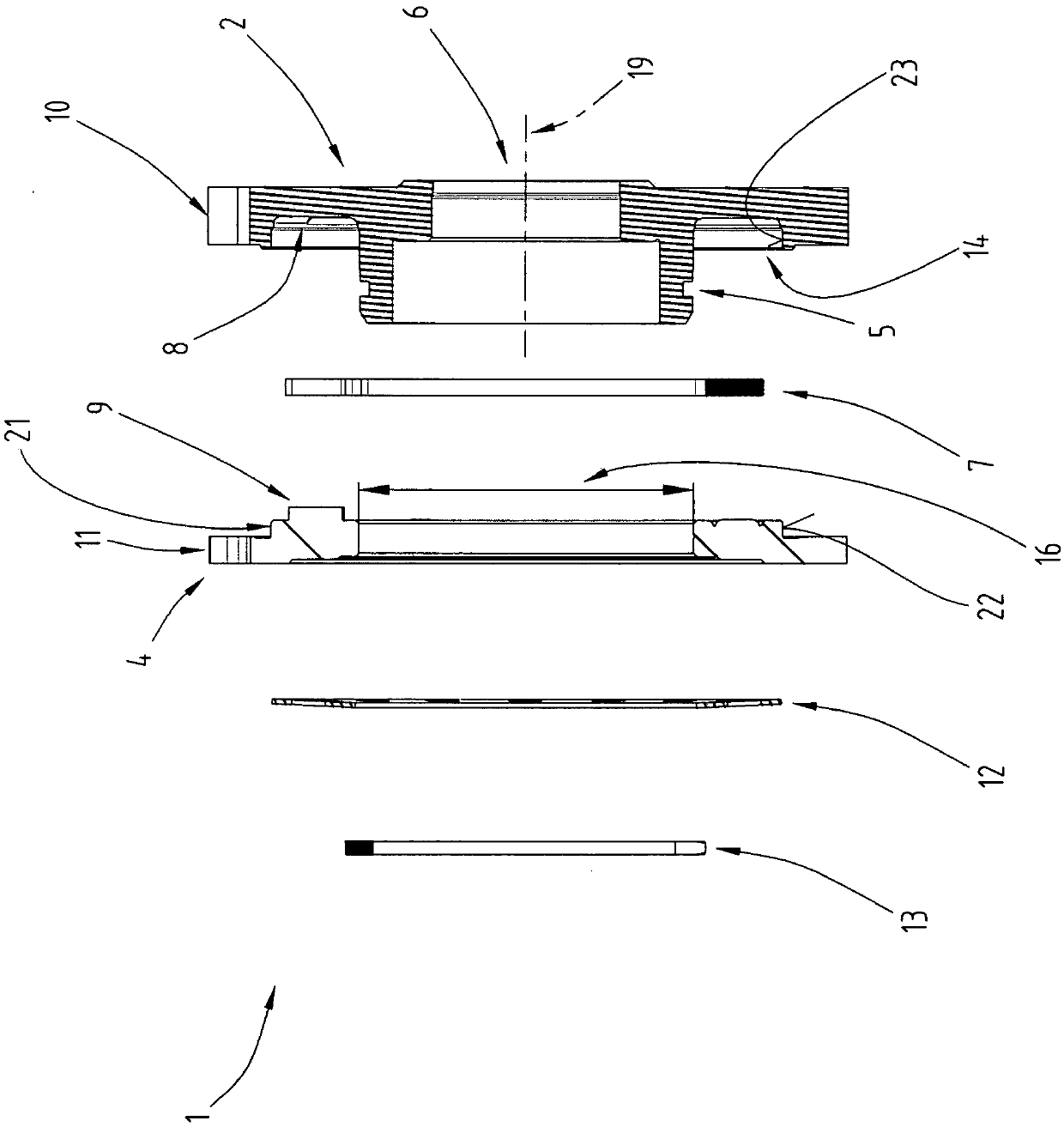

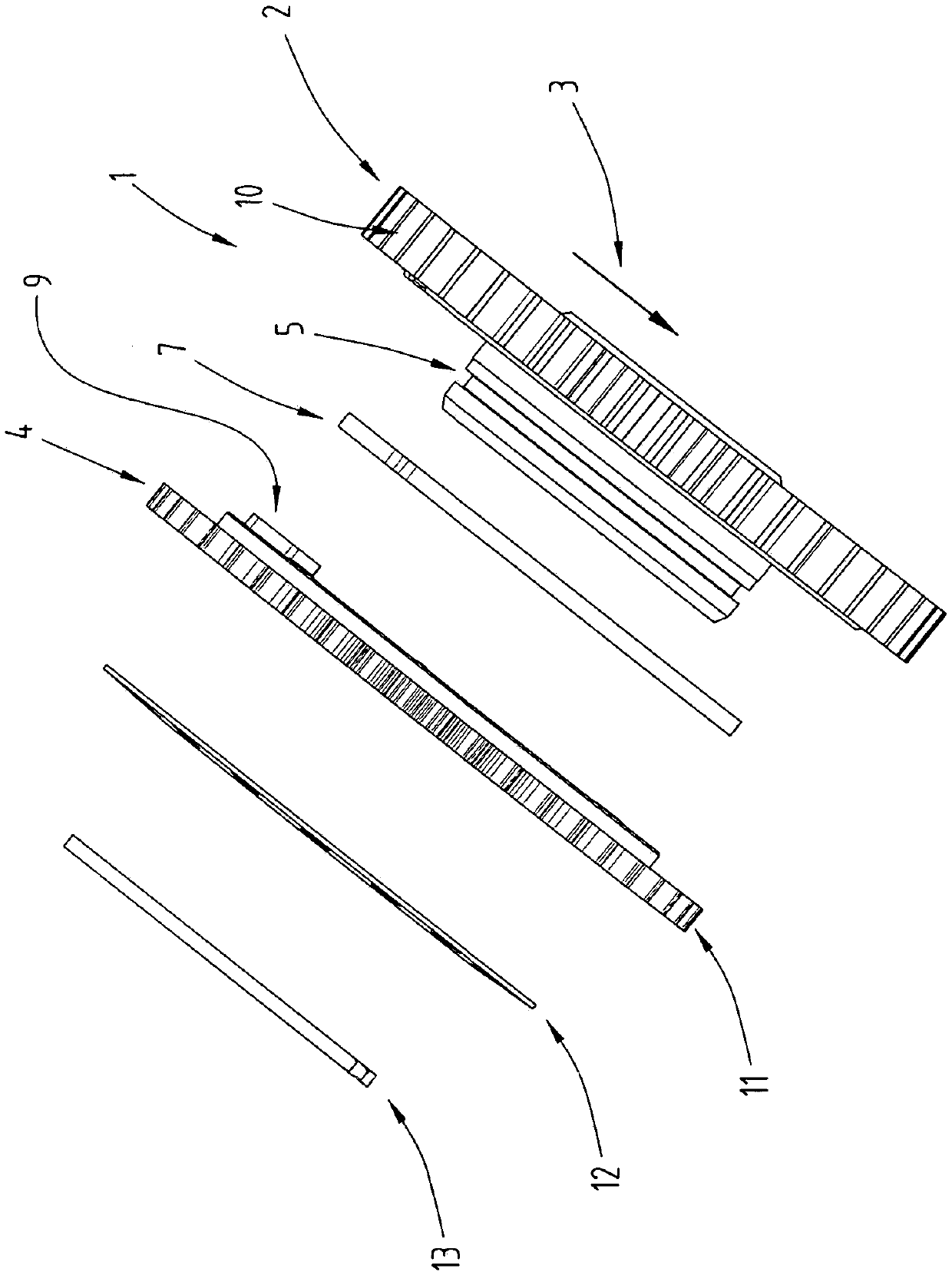

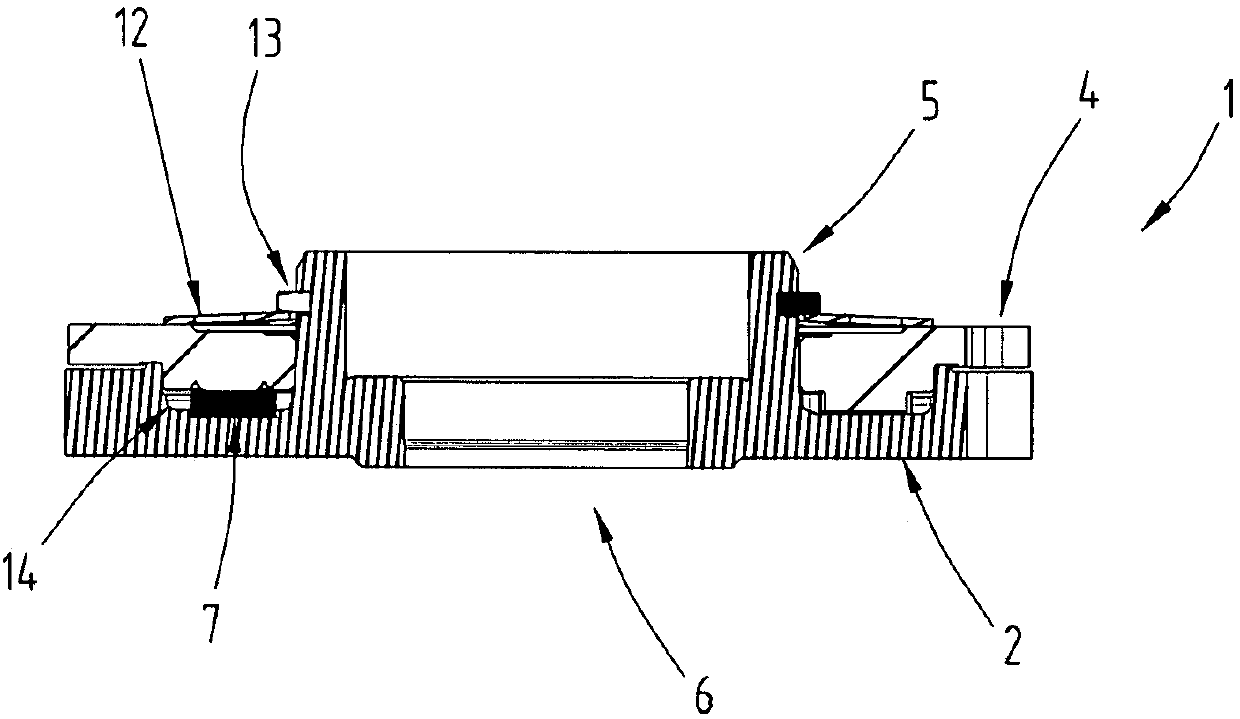

[0018] Figures 1 to 3 Shown is an exploded or cross-sectional view of the gear arrangement 1 . This gear arrangement 1, also referred to as a "split gear", has a main gear 2 and a gear 4 which is oppositely rotatable in the circumferential direction 3, wherein the main gear 2 has a hub 5 which In particular, it is integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com