A supersonic mandibular air intake front plug

An air intake and supersonic technology, applied in the field of ramjet engines, can solve problems such as high cost, dangerous aircraft platform, and air intake surge, and achieve the effects of low research and development costs and improved reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

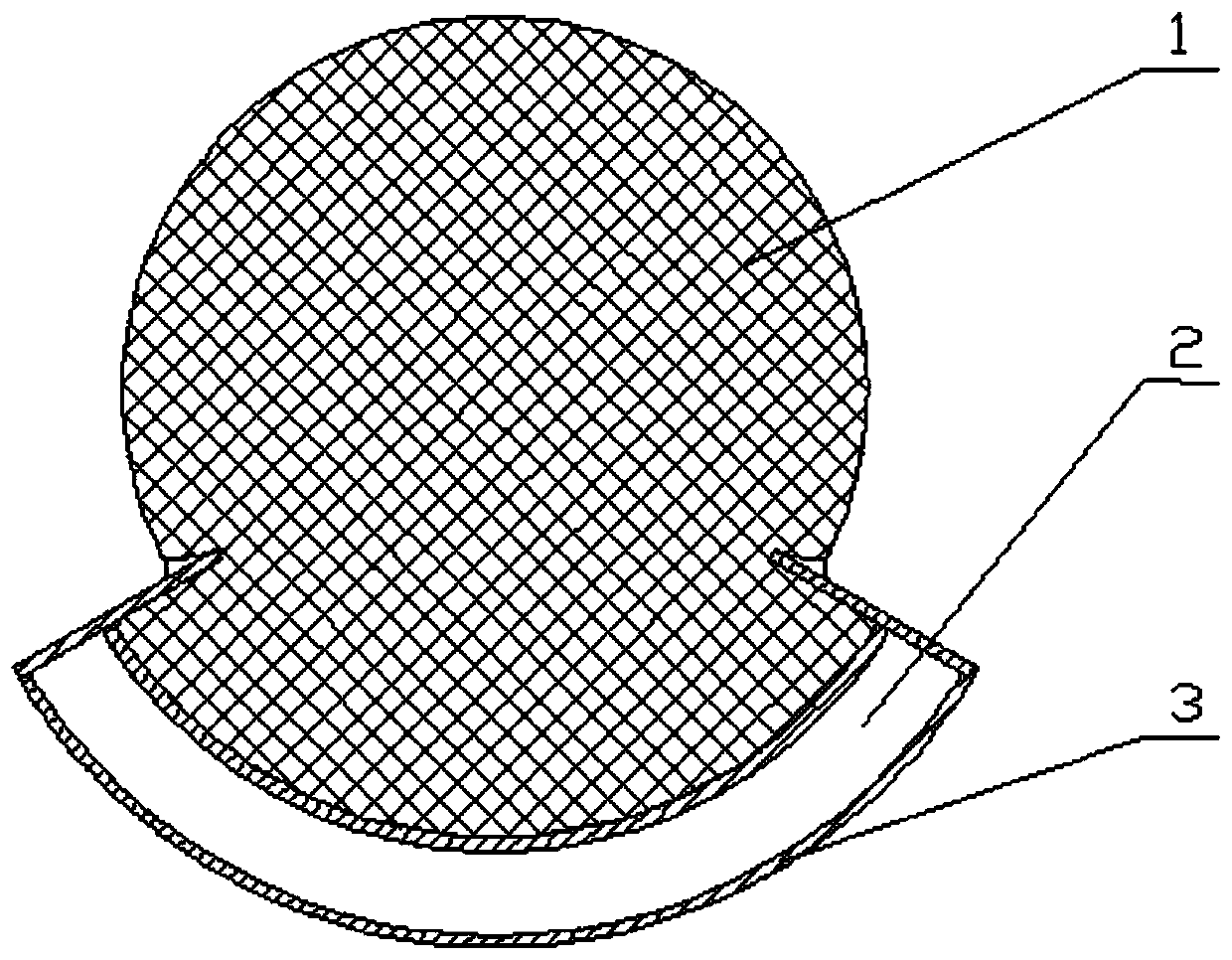

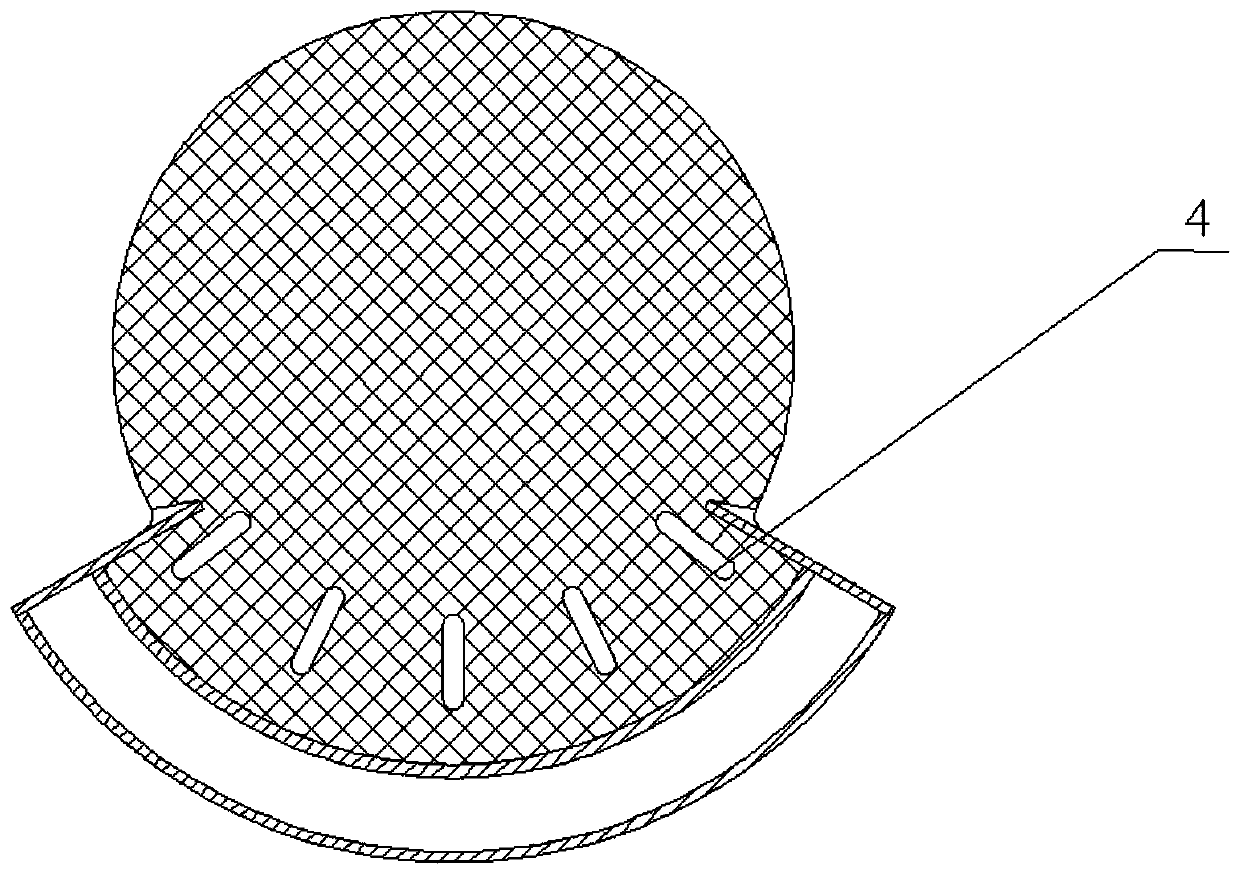

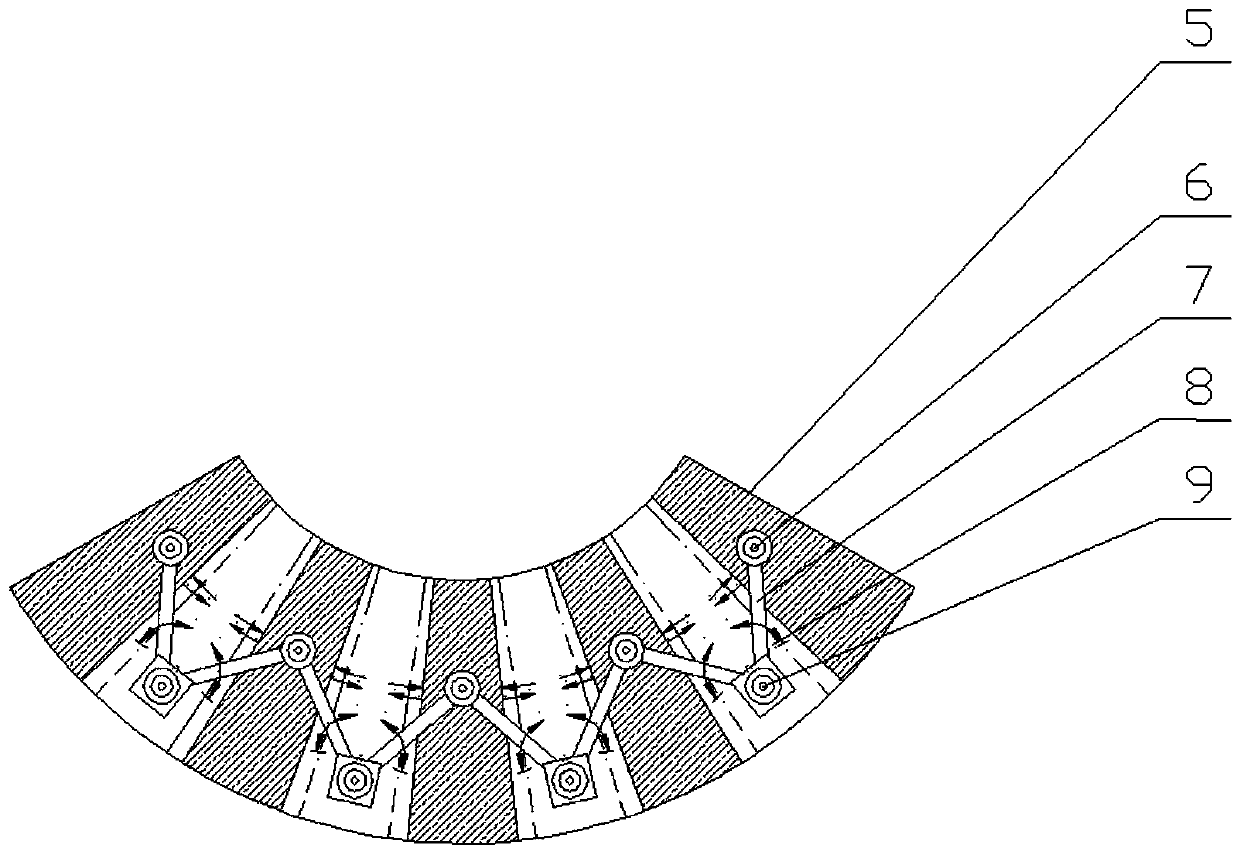

[0019] Please also see figure 2 , the supersonic mandibular air intake front plug of the present invention is installed on the aircraft head 1 and the air intake lip 3, and is used to close and open the air intake cavity 2, which includes a plurality of first regulating pieces 5, sliding pins 6 , connecting rod 7, some second adjusting pieces 8 and fixed pin 9. Wherein the first adjusting piece 5 and the second adjusting piece 8 are interlaced with each other, and all the first adjusting pieces 5 are on the same plane, and all the second adjusting pieces 8 are on another same plane, the first adjusting piece There is a height difference between the planes where the 5 and the second regulating piece 8 are located so as to be staggered from each other. In addition, the first adjusting piece 5 and the second adjusting piece 8 have the same width, so as to red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com