A rotating spindle crack detection device based on elastic wave detection

A rotating spindle, crack detection technology, applied in the direction of measuring device, generation of ultrasonic/sonic/infrasonic wave, analysis of solid by using sound wave/ultrasonic/infrasonic wave, etc. Problems such as the inability of the excitation device to be used directly to achieve the effect of avoiding safety risks and keeping the position consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

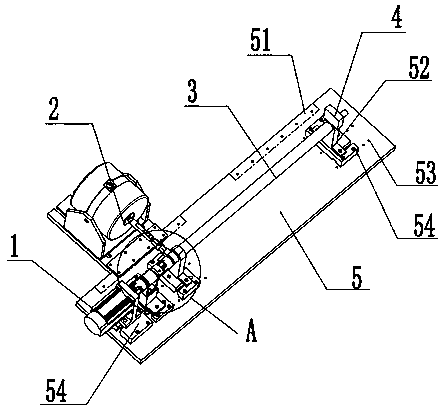

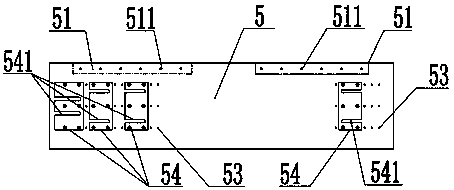

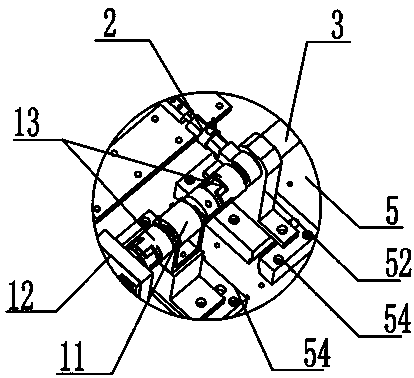

[0026] Such as figure 1 As shown, a rotating spindle crack detection device based on elastic wave detection includes a mounting plate on which a driving module 1 , an elastic wave excitation module 2 and an elastic wave receiving module 4 are detachably connected. The mounting plate includes a bottom plate and at least two rotating shaft fixing frames 52. The rotating shaft fixing frames 52 are used to fix the rotating shaft 3 to be tested, and the driving device is used to drive the rotating shaft to rotate at a high speed, so as to simulate the high-speed rotating shaft in the project in turn. . The drive module 1 and the rotating shaft fixing frame 52 are sequentially distributed along the length direction of the mounting plate 5 . The elastic wave excitation module 2 is located on one side of the mounting plate 5, excites the elastic wave and transmits it to the elastic wave receiving module 4 through the rotating shaft, and judges whether there is an inner part of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com