Flexible Spring Mounting Device

An installation device and a flexible spring technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low spring installation work efficiency, and achieve the effect of reducing labor workload, improving work efficiency, and shortening installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

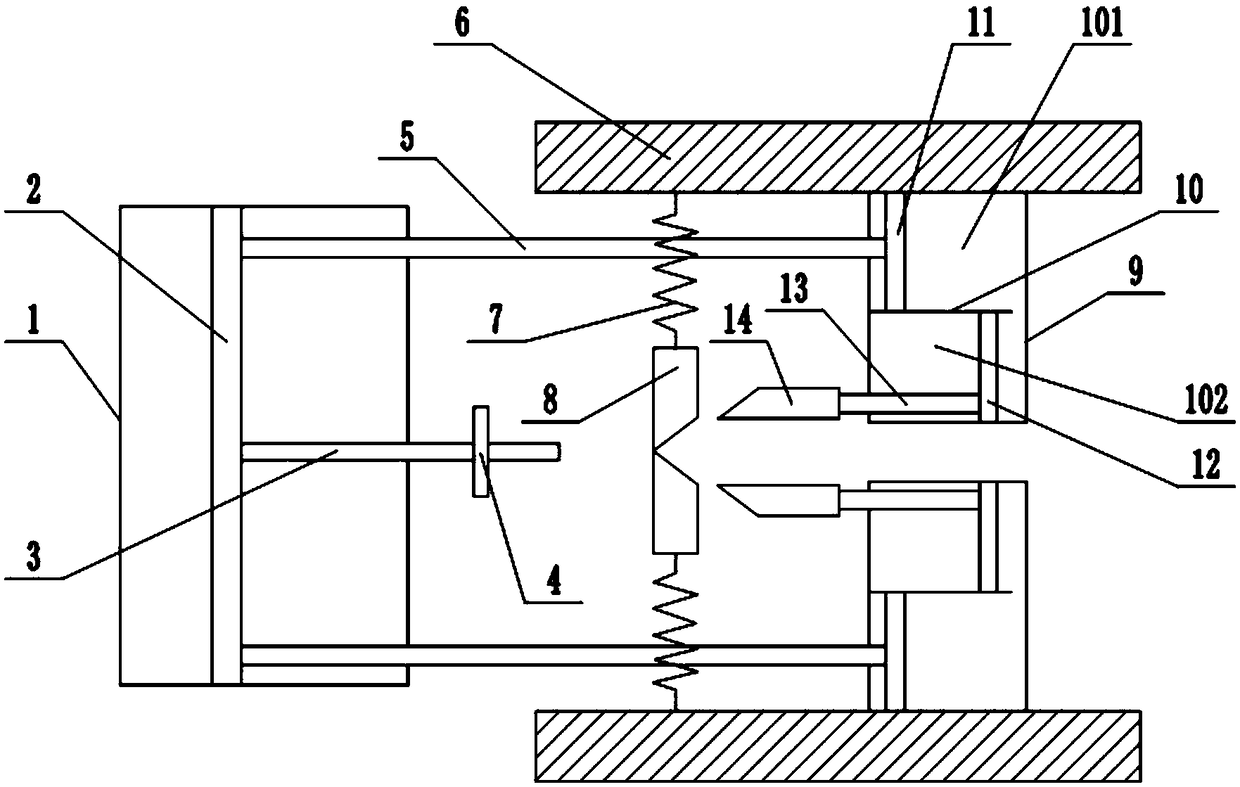

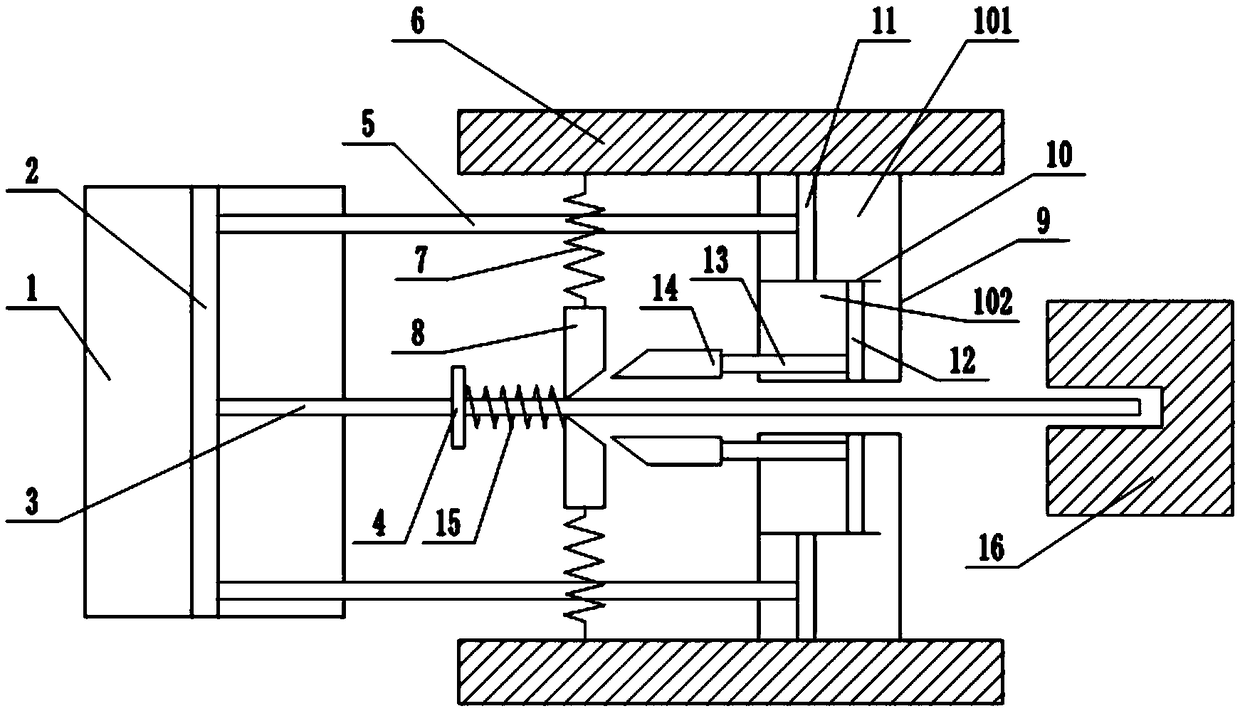

[0019] Such as figure 1 A flexible spring mounting device shown includes a first cylinder 1 , a fixed wall 6 , a wedge-shaped stop 8 and a wedge-shaped push block 14 . First cylinder 1 is provided with piston 2, and the right side of piston 2 is connected with spring guide rod 3 and two piston rods 5, and two piston rods 5 are positioned at the both sides of spring guide rod 3 respectively; Spring guide rod 3 is telescopic rod, And spring guide rod 3 is provided with baffle plate 4; A pair of fixed wall 6 is arranged on the both sides of spring guide rod 3 with spring guide rod 3 as central axis symmetry, and each side fixed wall 6 is provided with spring successively from left to right. 7 and the second cylinder 9; the spring 7 links to each other with the wedge-shaped block 8, and the wedge-shaped block 8 is provided with an arc groove 81 and a slideway 82, and the radius of the arc groove 81 is greater than or equal to the radius of the spring guide rod 3, Two wedge-shaped...

Embodiment 2

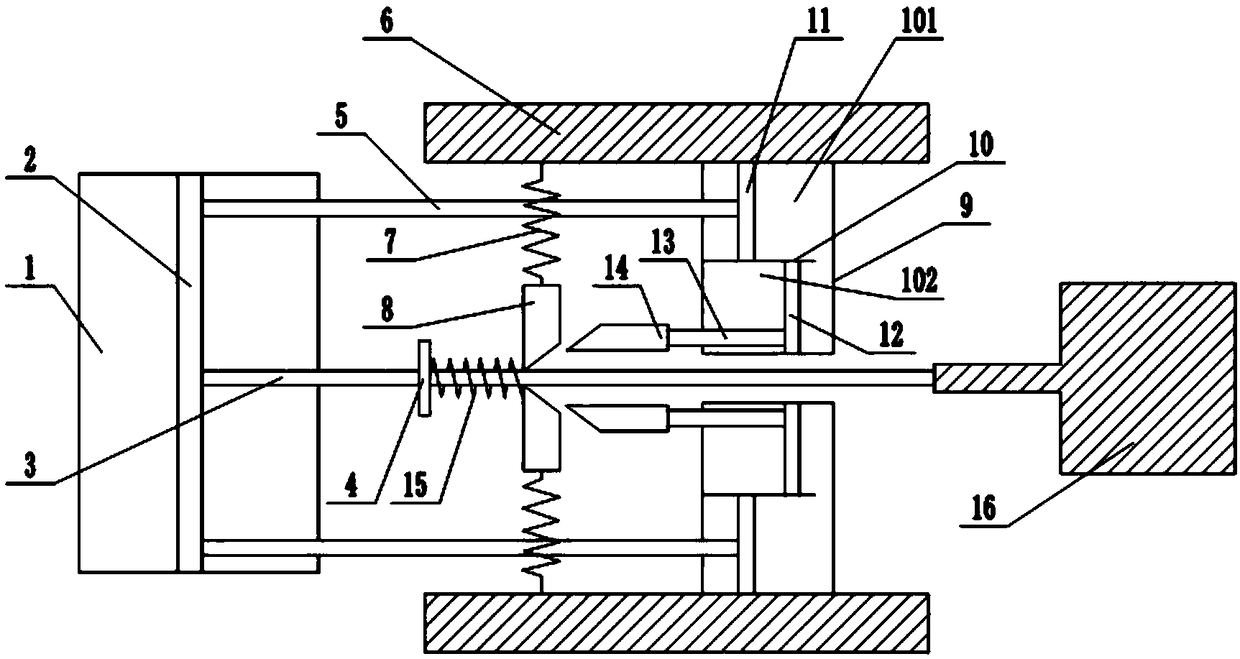

[0022] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, when the flexible spring 15 is installed on the shaft of the workpiece 16, the rightmost end of the spring guide rod 3 is against the shaft of the workpiece 16, and when the first cylinder 1 pushes the spring guide rod 3, due to the front end of the spring guide rod 3 and the When the shafts are offset, the spring guide rod 3 shrinks, so that the stroke path of the flexible spring 15 is shortened, and the installation time of the flexible spring 15 is shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com