A method for preventing and arresting cracking at right-angled corners of openings in enclosures of ship metal structures

A metal structure and wall technology, which is applied in ship construction, ship design, ship parts, etc., can solve the problems of increased plate thickness, difficult grinding, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

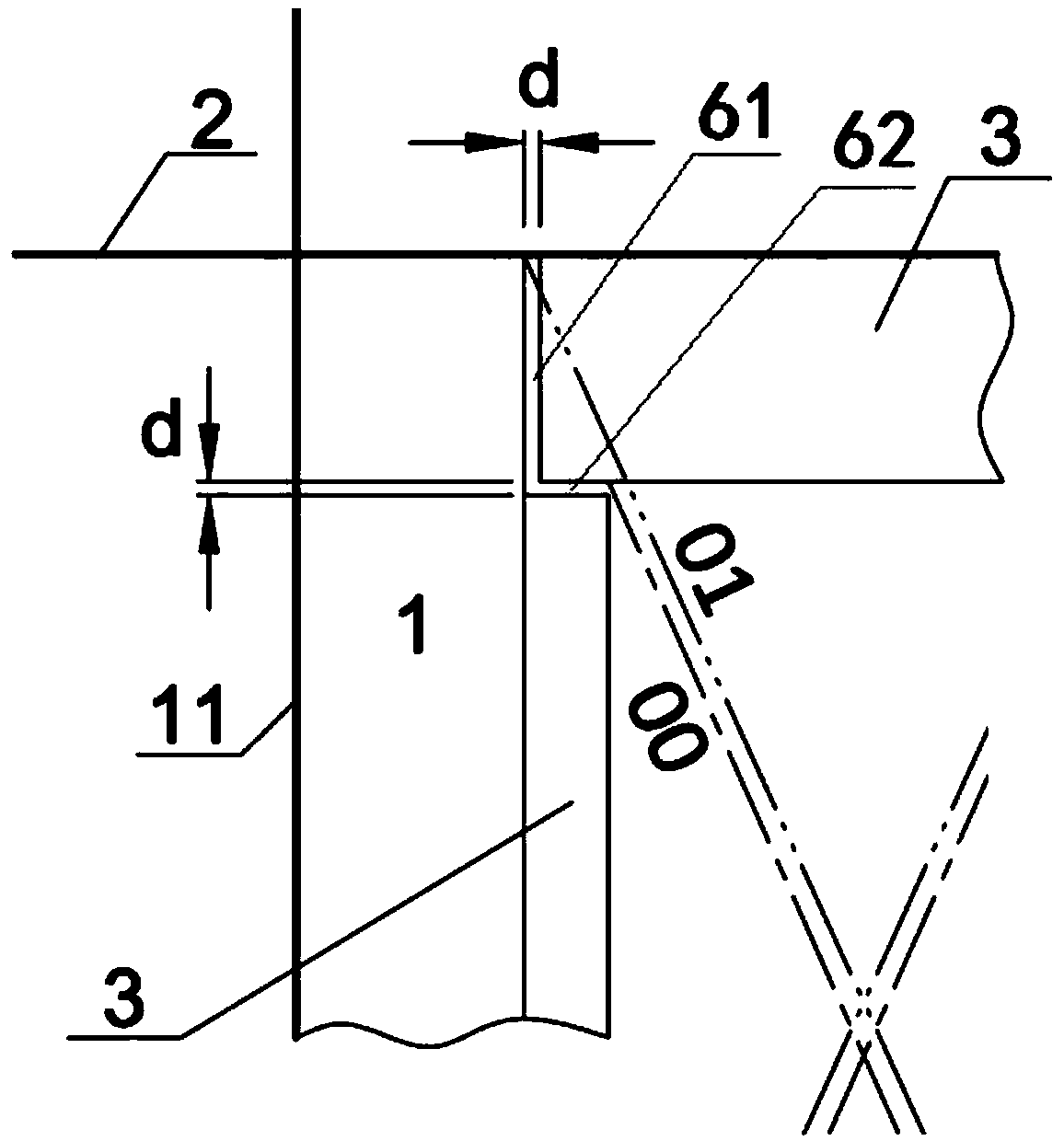

[0147] Such as figure 2 As shown, it is the basic node form of the stress transfer mode in this embodiment. The method for crack prevention and crack arrest at right-angled corners of the opening of the metal structure enclosure of the ship in this embodiment includes the following steps:

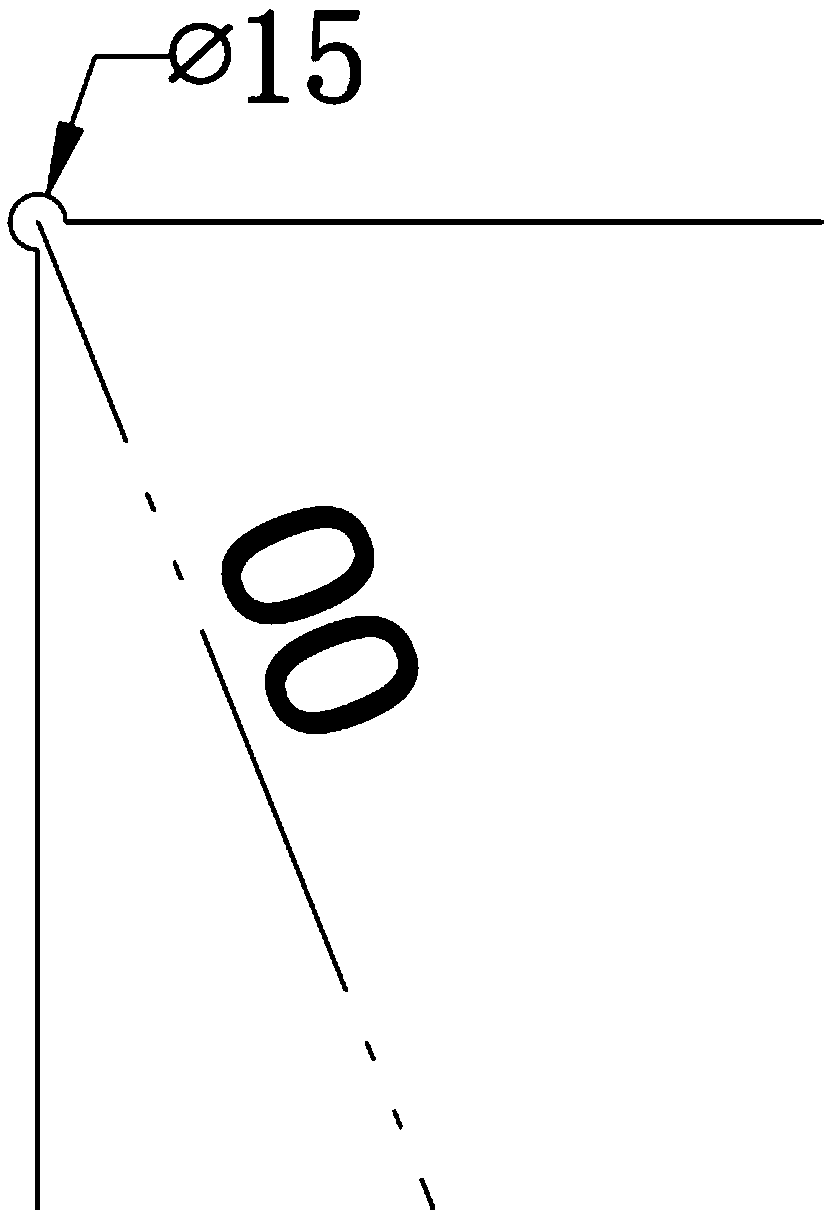

[0148] Step 1. Expand the designed opening 00 of the surrounding wall 1 until the upper deck 2 or / and the lower deck 20 form a through-shaped enlarged opening (hereinafter referred to as "through opening");

[0149] Step 2. Along the edge of the through opening 01, according to the position and size of the designed opening 00, respectively weld the slats 3 filled with homogeneous materials;

[0150] Step 3, a vertical anti-crack 61 is left between the slat 3 and the edge of the through opening 01, and a transverse anti-crack 62 is left between adjacent slats 3;

[0151] Step 4. Carry out corresponding finite element calculation and analysis on the through opening 01 and its directly relat...

Embodiment 2

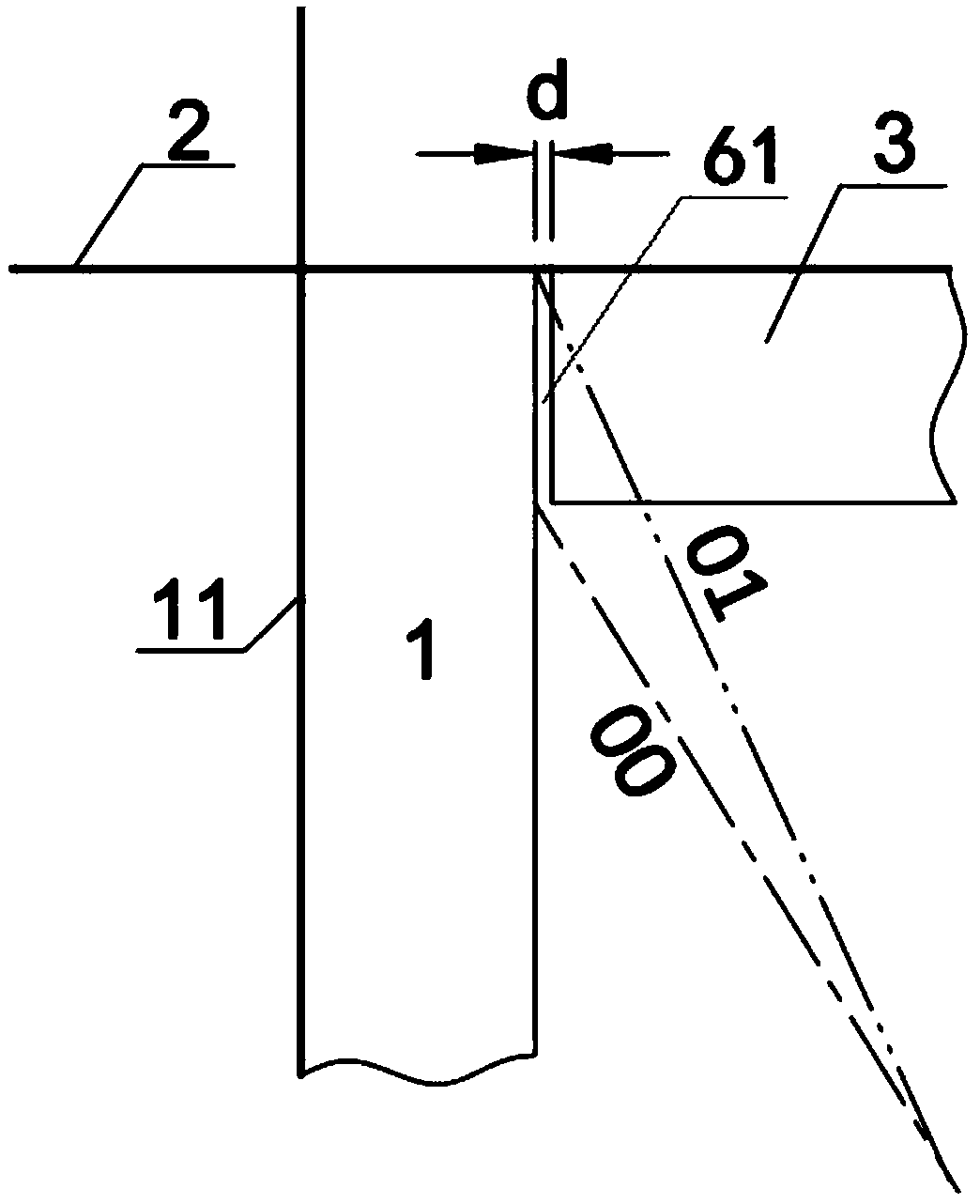

[0158] Such as image 3 As shown, this embodiment is a simplified variant of the above-mentioned stress transfer basic node form. The method for preventing and arresting cracks at right-angled corners of the enclosure wall openings of ship metal structures in this embodiment includes the following steps:

[0159] Step 1. Expand the opening of the surrounding wall 1 with the same width as the designed opening 00 until the upper deck 2 or / and the lower deck 20 form a through opening 01;

[0160] Step 2, along the upper (and / or lower) edge of the through opening 01, respectively weld the slats 3 filled with homogeneous materials according to the height dimension of the designed opening 00;

[0161] Step 3, a vertical crack 61 is left between the slat 3 and the edge of the through opening 01;

[0162] Step 4. Carry out corresponding finite element calculation and analysis on the through opening 01 and its directly related structures formed in the above step 3, and calculate the s...

Embodiment 3

[0168] Such as Figure 4 As shown, it is a lateral steering variant of the aforementioned stress transfer basic node form. The method for crack prevention and crack arrest at right-angled corners of the ship metal structure enclosure wall opening in this embodiment includes the following steps:

[0169] Step 1. Expand the designed opening 00 of the surrounding wall 1 until the left intersecting surrounding wall 11 or / and the right intersecting surrounding wall 12 form a through opening 01;

[0170] Step 2, along the edge of the through opening 01, weld the slats 3 filled with homogeneous materials according to the position and size of the designed opening 00;

[0171] Step 3: A horizontal anti-crack 62 is left between the slat 3 and the edge of the through opening 01, and a vertical anti-crack 61 is left between adjacent slats 3;

[0172] Step 4. Carry out corresponding finite element calculation and analysis on the through opening 01 and its directly related structures forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com