A Design Method for Glass Fiber Composite Crack Stopper Used in x100 Gas Pipeline

A glass fiber and composite material technology, applied in the direction of pipeline damage/wear prevention, pipeline protection, pipeline system, etc., can solve the problems of limiting the application of glass fiber composite material crack arrester, lack of design methods, etc., to achieve large-scale application, The design process is simple and easy to implement, and the effect of improving design accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0056] The present invention is used for the design method of glass fiber composite crack stopper of X100 gas transmission pipeline, comprises the following steps:

[0057] 1) Calculate the pipe stress ratio according to the pipe structure and stress parameters;

[0058] Calculate according to the following formula:

[0059]

[0060] Among them, F is the stress ratio of the pipeline; P is the internal pressure of the pipeline; D is the diameter of the pipeline; R t0.5 is the yield strength of X100 steel pipe, and t is the pipe wall thickness. R t0.5 It shall be obtained by steel pipe transverse round bar tensile test according to ASTM A370.

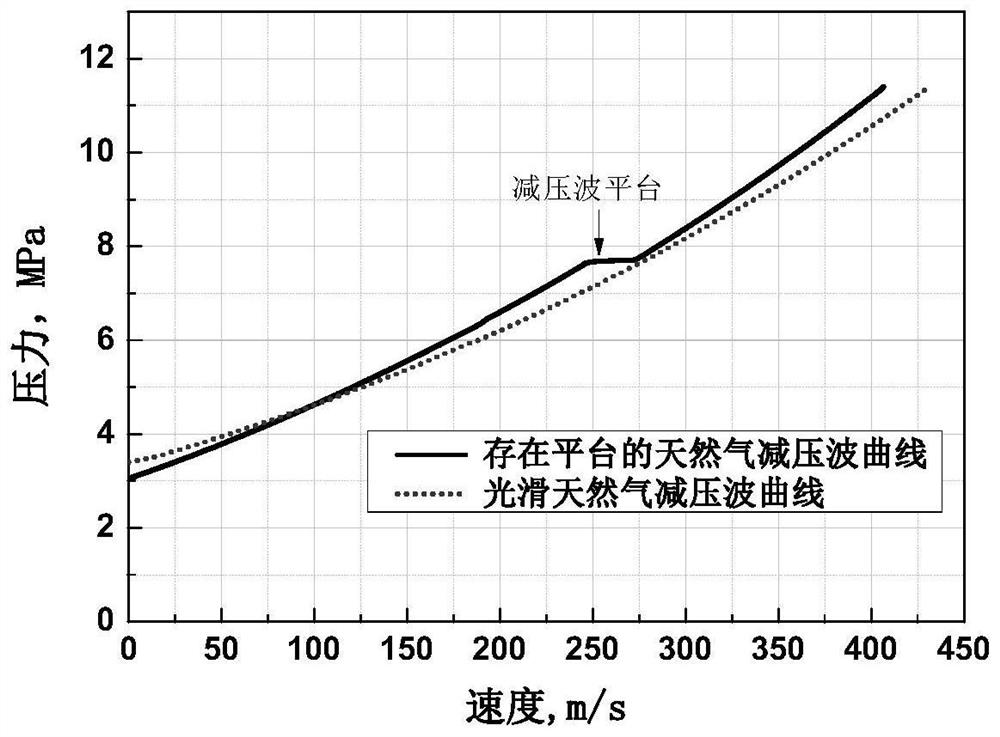

[0061] 2) According to the pipeline tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com