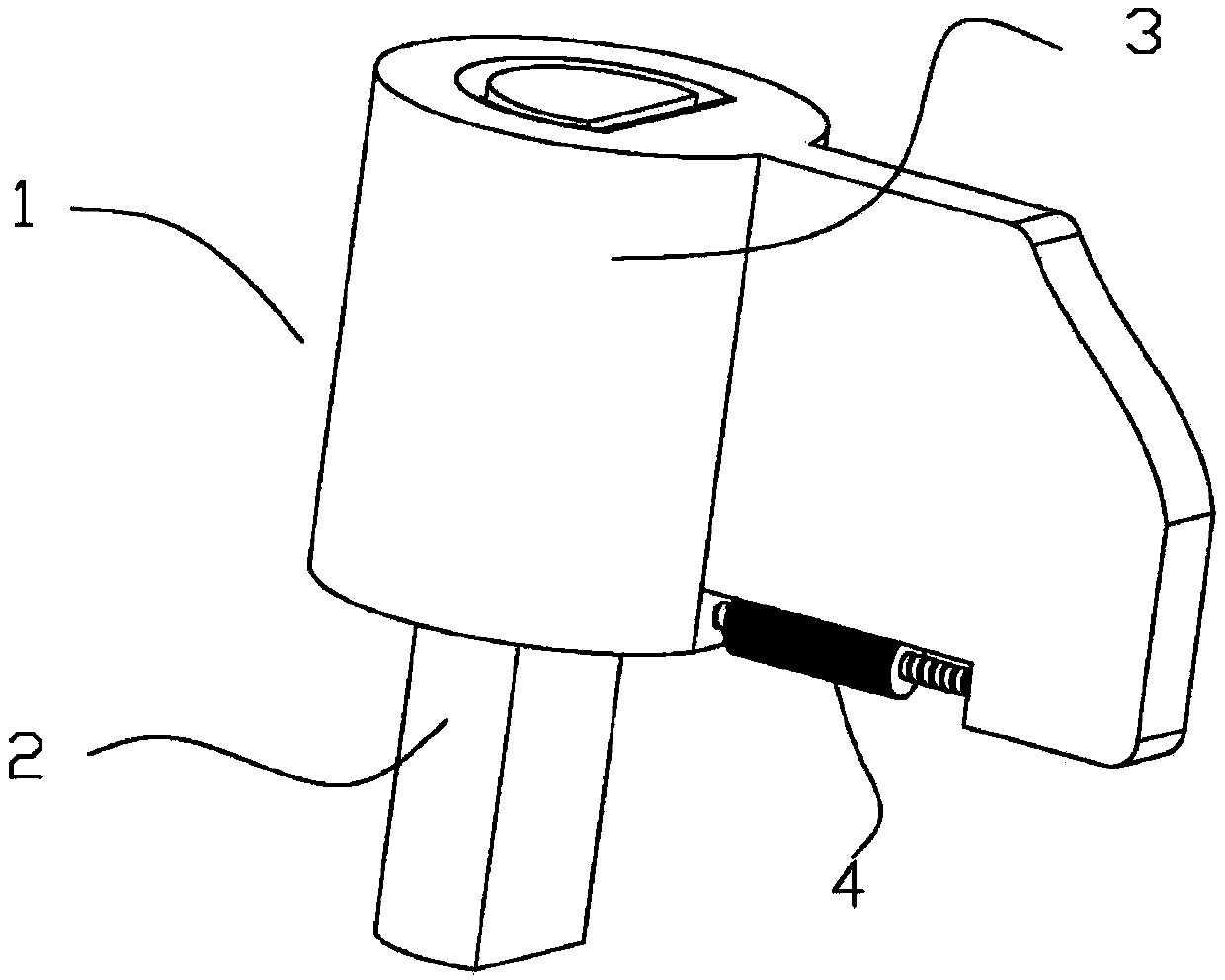

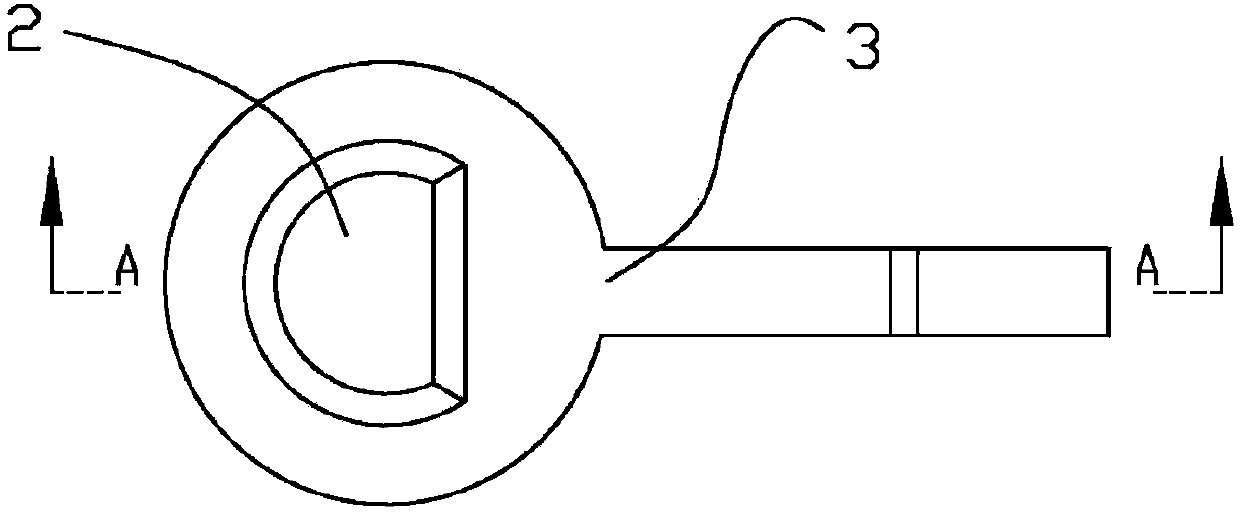

Bread maker stirring device with locking structure

A mixing device and locking structure technology, applied in dough mixers, structural components of mixing/kneading machines, baking, etc., can solve problems such as falling off of the mixing head, falling out of the mixing head, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

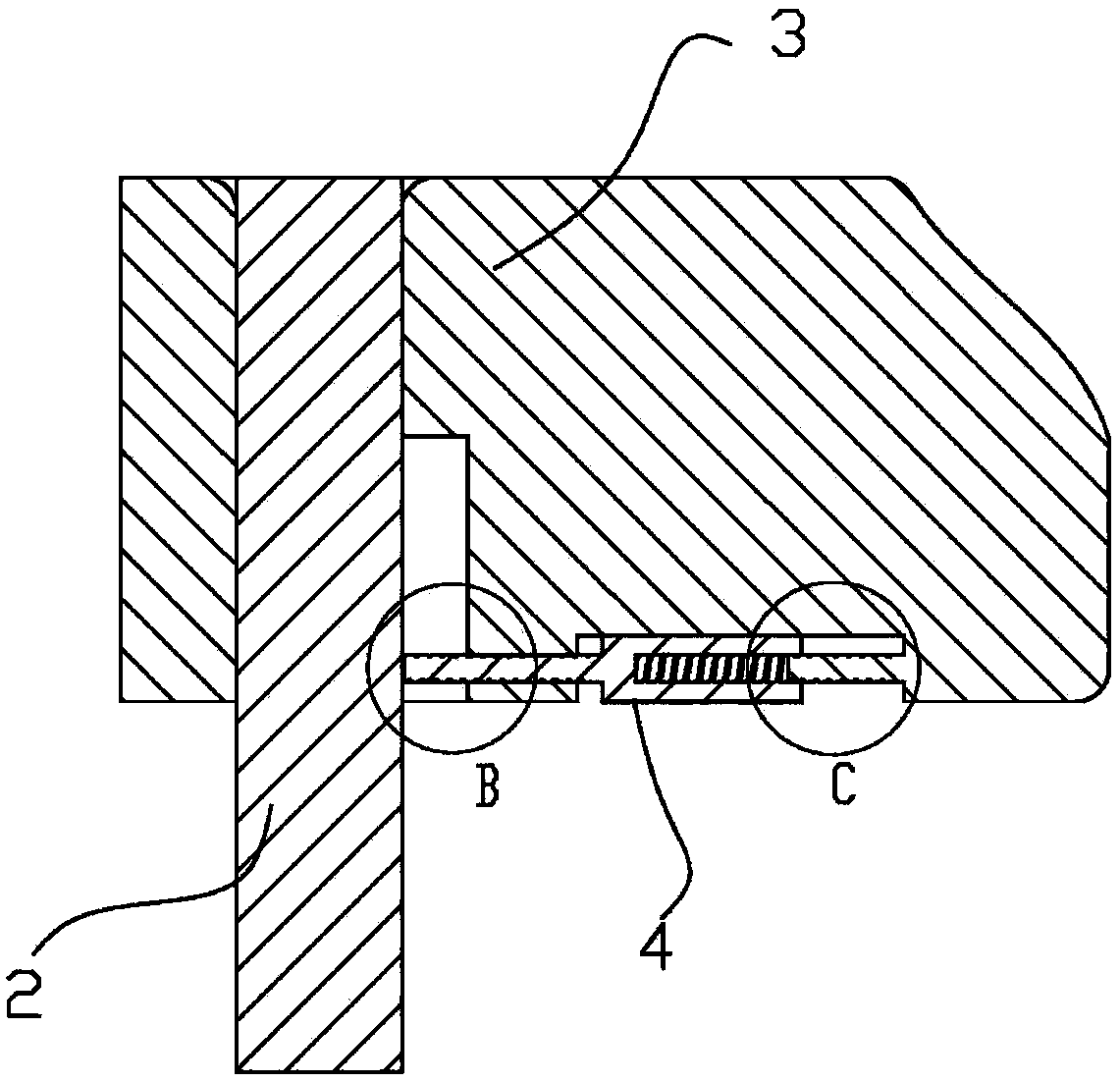

[0039] Such as Figure 14 As shown, it is the third embodiment of the mixing device for bread machine with locking structure of the present invention. The difference from the second embodiment is that a circular positioning sinker 221B is provided in the middle of the stirring shaft 2B. The diameter of the positioning sinker 221B is larger than the outer diameter of the second locking shaft 42 of the locking head 4 .

[0040] When the locking head 4 is dialed to the locking position, the second locking shaft body 42 of the locking head 4 extends into the positioning sinker 221B. It should be noted that the head of the second locking shaft 42 does not directly contact the bottom of the positioning sinker 221B.

[0041] After the baking is finished, during the demoulding process of the bread, since the second locking shaft body 42 of the locking head 4 is always restricted in the positioning sinker 221B, the stirring head 3 will not come out along with the bread.

[0042] Beca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap