Inclined lifting pin fixing structure easy to maintain

A technology of pin fixing and slanting top, which is applied in the field of machinery, can solve problems such as damaged molds, pins falling out, accidents and cost increases, and achieve the effect of reducing costs and accident rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

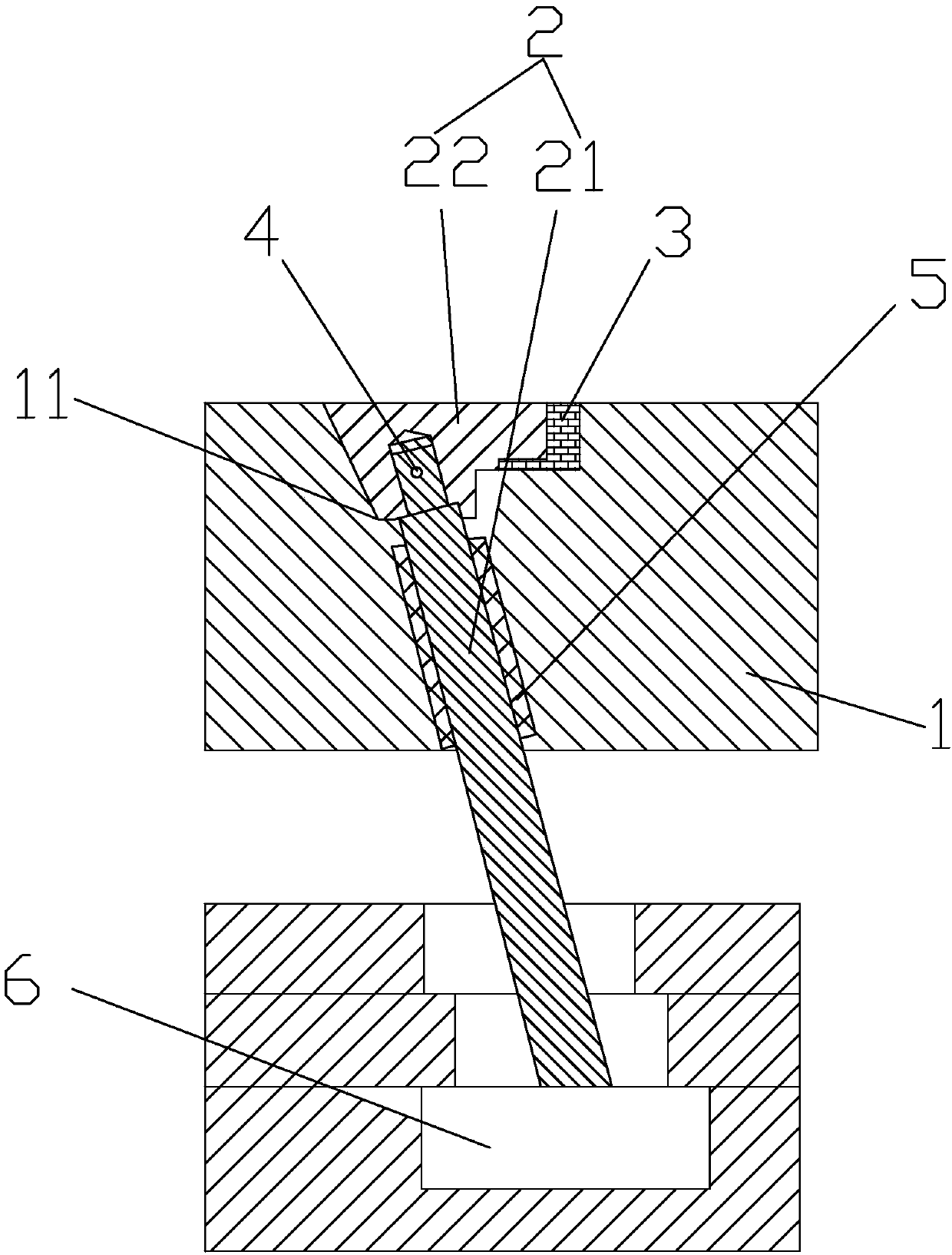

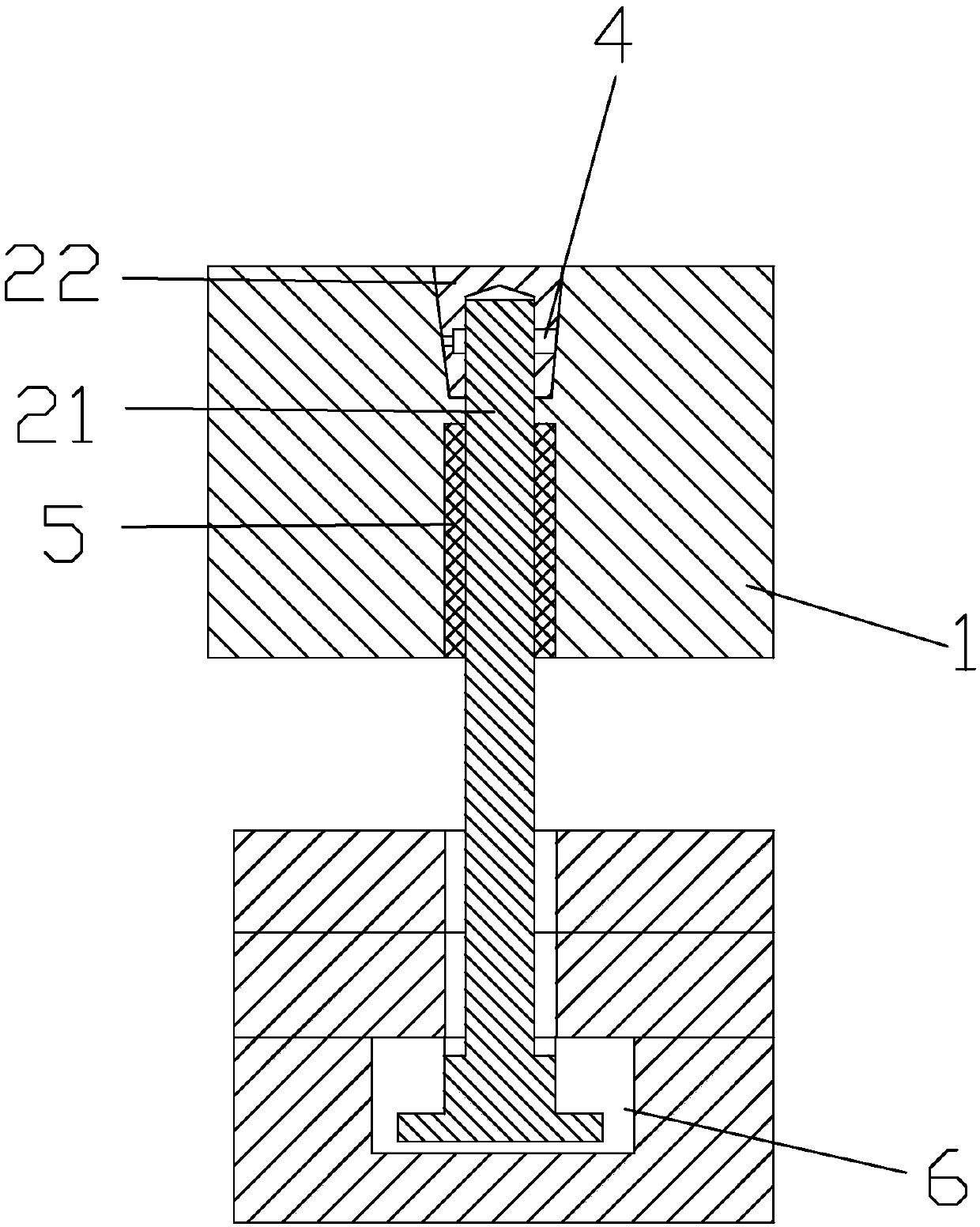

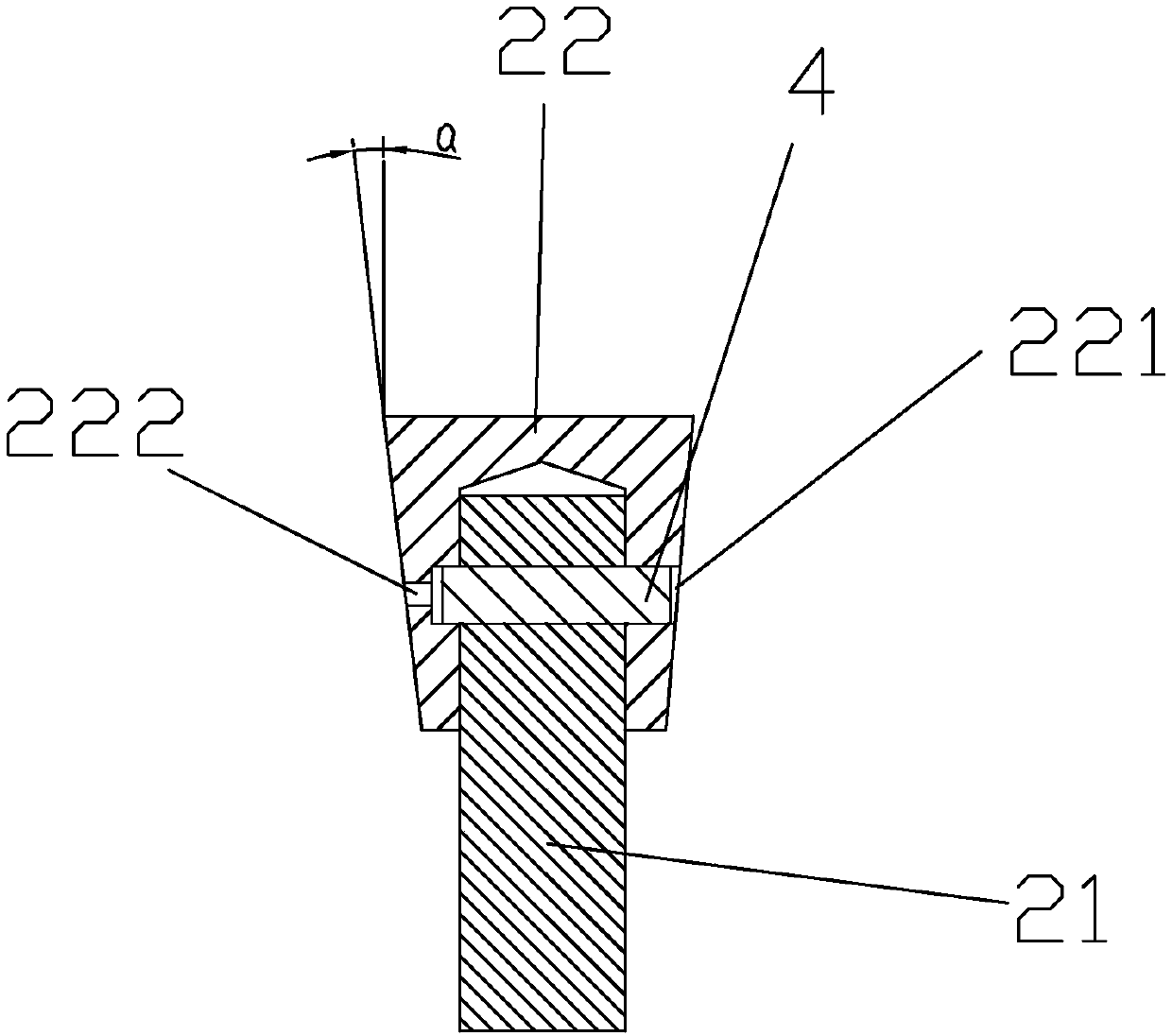

[0017] Such as Figure 1 to Figure 3 As shown, in this embodiment, an easy-maintenance tilting pin fixing structure is characterized in that it includes a lower mold 1, and the lower mold 1 is provided with a slope groove 11, and the slope groove 11 is equipped with a groove for The inclined roof 2 ejected from the product 3 on the lower mold 1, the inclined roof 2 comprises an inclined ejector rod 21 and an inclined ejector block 22, the inclined ejector block 22 is fixed on one end of the inclined ejector rod 21 by a latch 4, and the inclined ejector One side of the block 22 is provided with a through hole 221 for inserting the latch 4 and fixing the inclined ejector rod 3, and the other side of the inclined ejector block 22 is provided with an ejection hole 222 communicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com