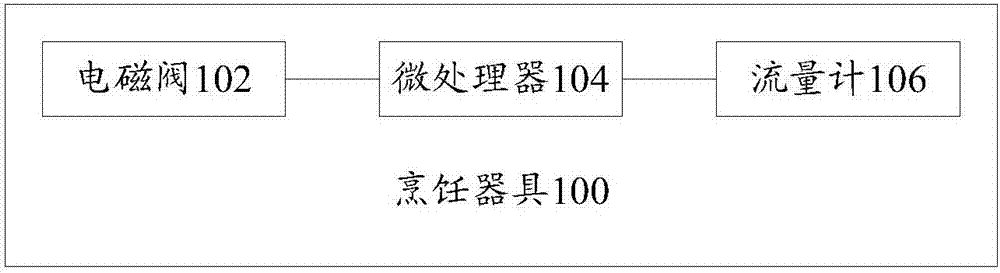

Cooking appliance, flow control method and flow control device

A technology of cooking utensils and flow value, which is applied to cooking utensils, household utensils, kitchen utensils, etc., can solve the problems of control process deviation and poor flexibility in the cooking process, and achieves fast action, sensitive response, and reduces the possibility of dry burning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

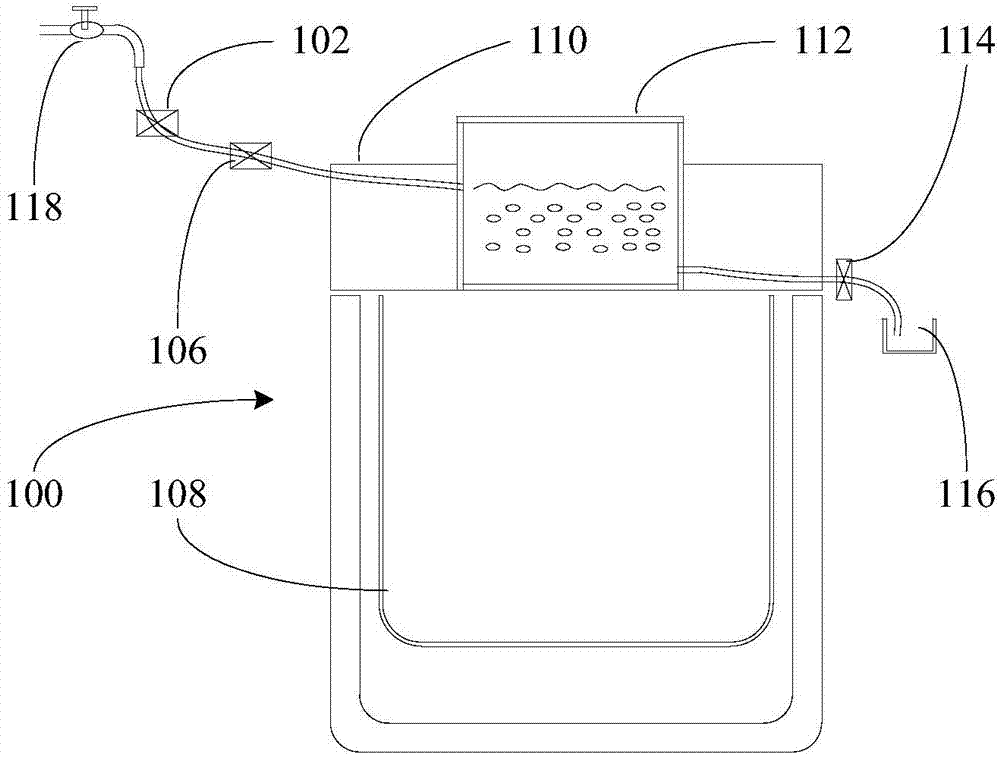

Embodiment 1

[0062] When the microprocessor 104 controls the pulse solenoid valve 102 to open and the frequency of the unit pulse signal is 10 Hz, the microprocessor 104 counts 600, and the flow rate is 2L.

Embodiment 2

[0064] When the microprocessor 104 controls the pulse solenoid valve 102 to open and the frequency of the unit pulse signal is 20 Hz, the flow rate is 2L when the microprocessor 104 counts 600, and the flow rate is 4L when the microprocessor 104 counts 1200.

Embodiment 3

[0066] When the microprocessor 104 controls the pulse solenoid valve 102 to open and the frequency of the unit pulse signal is 30 Hz, the flow rate is 2L when the microprocessor 104 counts 600, and the flow rate is 6L when the microprocessor 104 counts 1800.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com