Piling car structure with side bumpers

A stacker truck and bumper technology, applied in the field of stacker truck structure, can solve problems such as inconvenience in removing goods, and achieve the effect of good anti-side collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

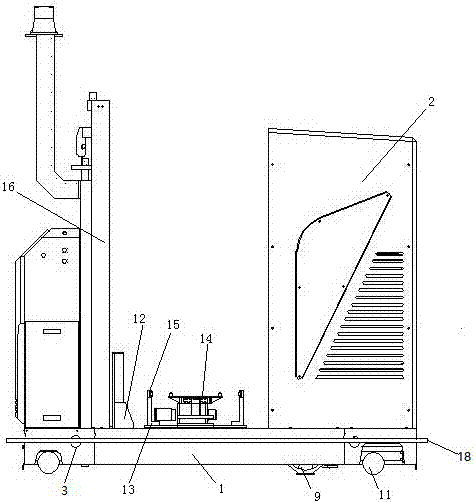

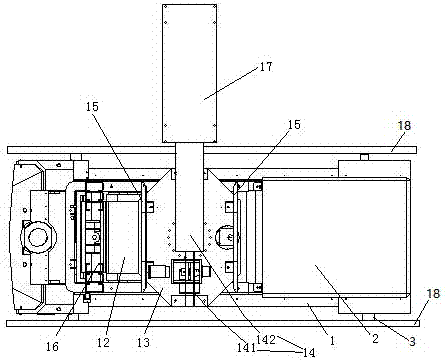

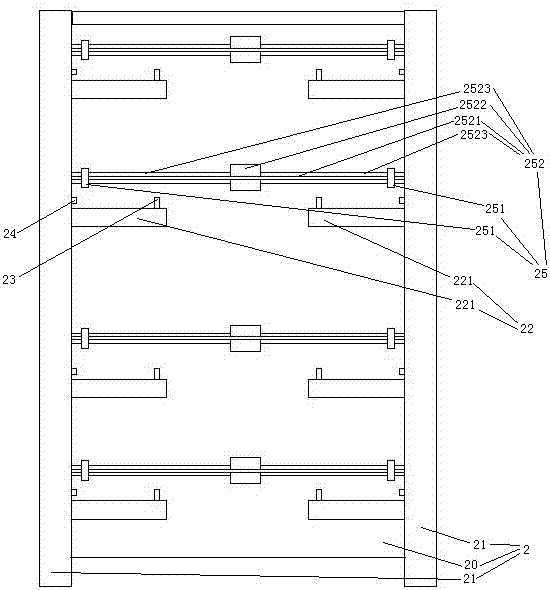

[0030] see figure 1 , a stacker truck structure with side bumpers, including two side bumpers 18, wheels 11, a base 1 supported on the wheels and a power source for driving the wheels. The power source is the drive motor 6. The base 1 can certainly turn along the left and right directions when walking. The middle part of the base 1 is provided with a lifting seat 12 . The lifting base 12 is provided with a rotating base 13 and a rotating structure (not shown in the figure) that drives the rotating base to rotate on a horizontal plane. The rotating base 13 is provided with a telescopic slide rail 14 capable of outputting the rotating base, a telescopic structure (not shown in the figure) that drives the telescopic slide rail to slide, and two limit slide rails 15 located on both sides of the telescopic slide rail. The rear end of the base 1, namely t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com