Full steering chassis

A full-steering, chassis-based technology, applied to steering mechanisms, steering rods, electric steering mechanisms, etc., to achieve high-speed feed, easy-to-understand design process, and easy-to-understand design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

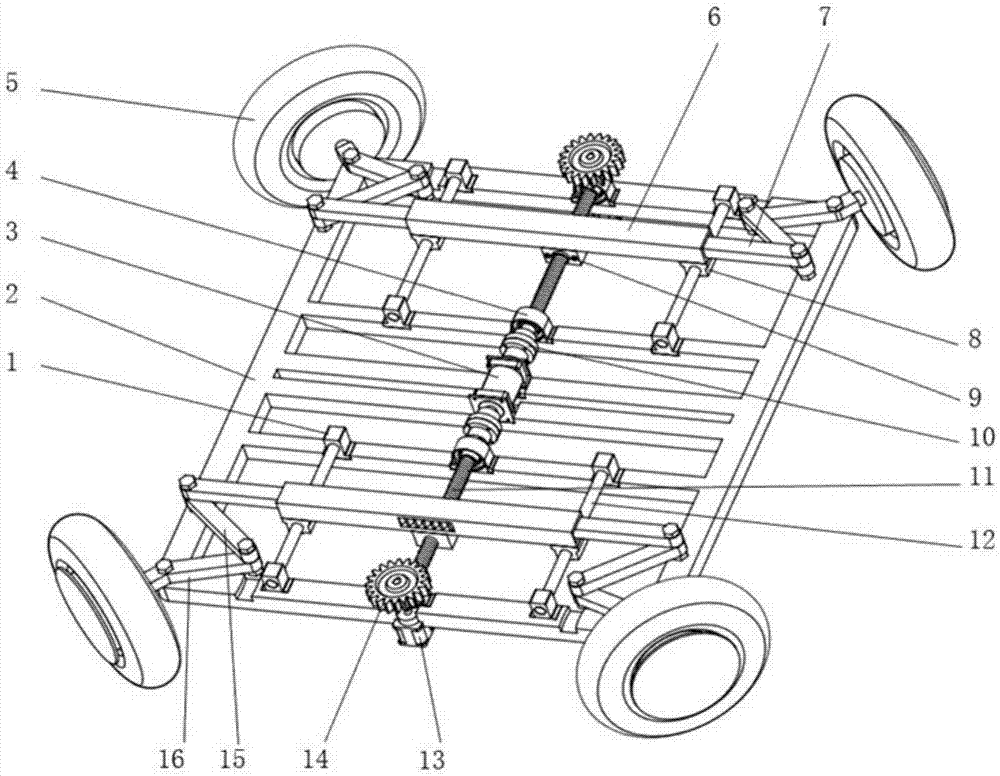

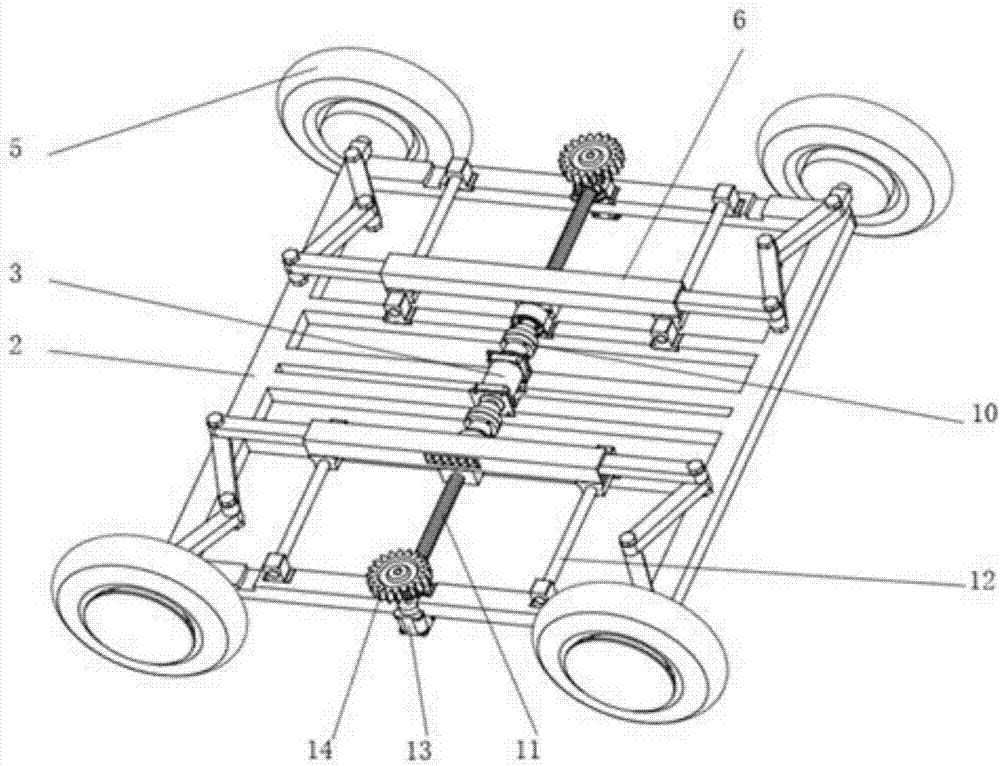

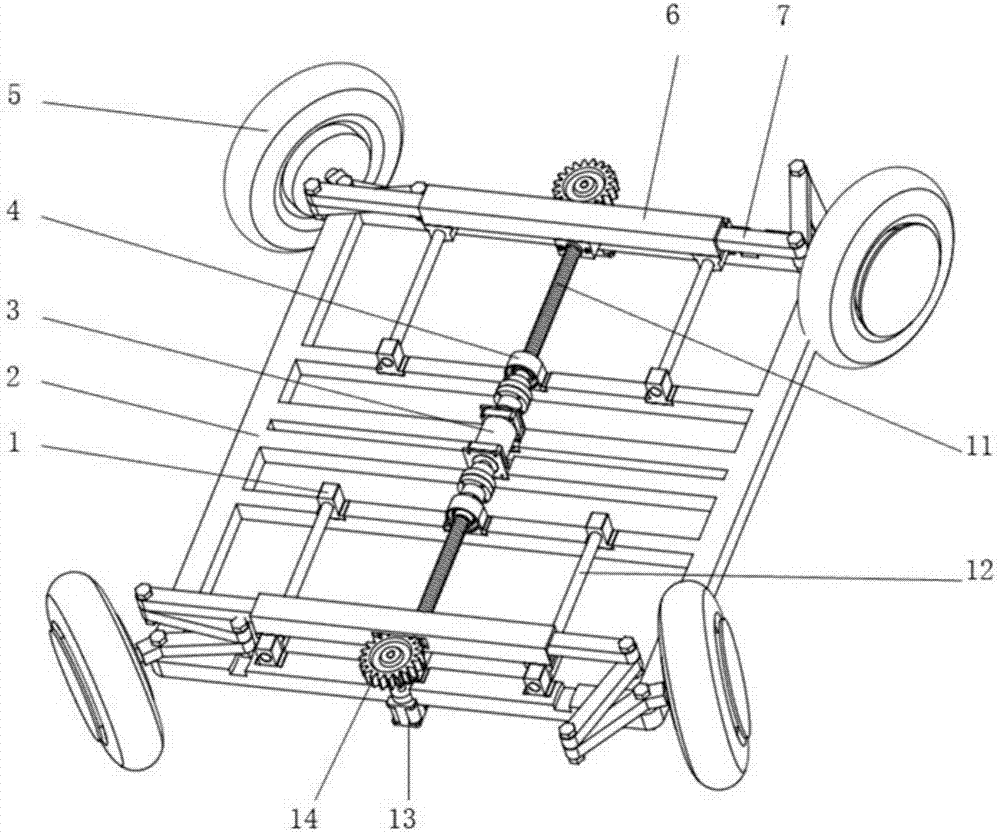

[0026] A full-steering mechanism of an intelligent inspection vehicle for an underground pipe corridor, the mechanism includes a guide rail support 1, a chassis 2, a first stepping motor 3, an angular contact ball bearing with a vertical seat 4, a hub motor and a brake disc Wheel 5, rack sleeve 6, rack 7, slider 8, nut slider 9, coupling 10, lead screw 11, longitudinal guide rail 12, second stepping motor 13, gear 14, connecting rod 15, curved Rod 16. Its main technical solution is: the chassis 2 has a square structure, and the first stepper motor 3 with double output shafts is installed longitudinally in the middle, and the motor shaft and the lead screw 11 are connected through a coupling 10; angular contact ball bearings 4 with vertical seats and The guide rail support 1 is fixed on the chassis 2, the lead screw 11 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com