Hanging column with overhanging function and fixing method

A hanging column and functional technology, which is applied in the field of suspension function hanging column and fixing, can solve the problems of complex and laborious fixing process of keel and fixed beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

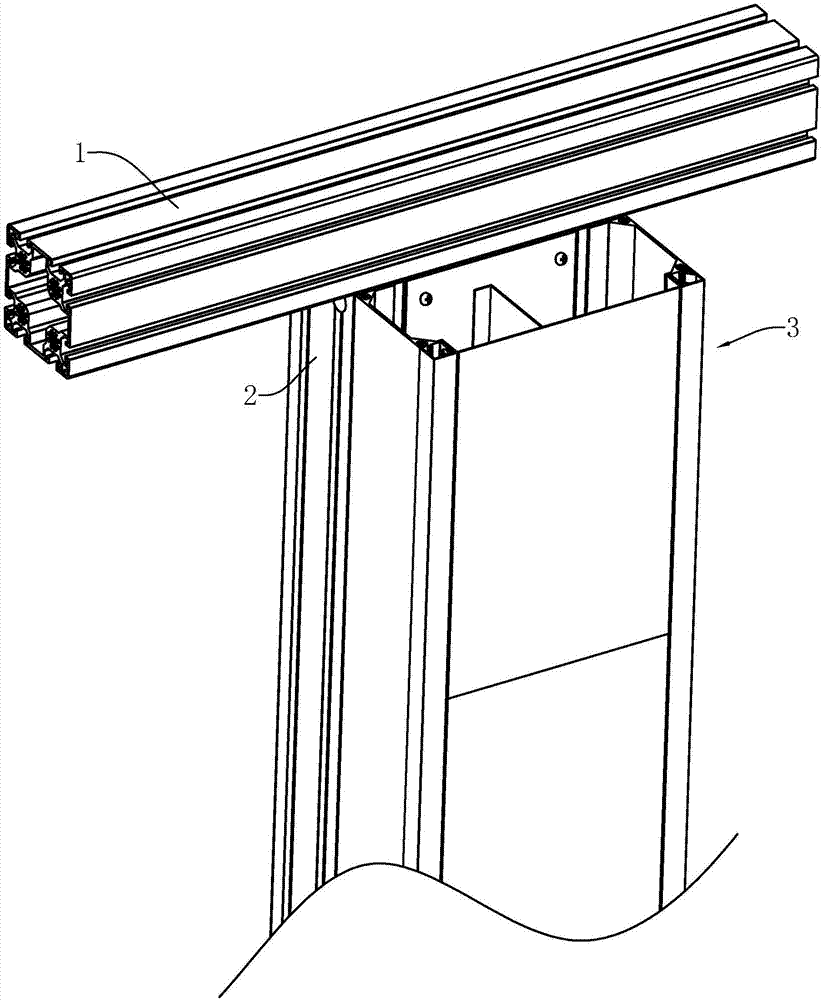

[0047] Such as figure 1 As shown, a suspension functional column includes two fixed beams 2 and a plurality of functional boxes 3, the two fixed beams 2 are vertically arranged, the functional boxes 3 are hollow tubular, and the functional boxes 3 are spliced with each other up and down, the function The box 3 is fixedly connected with the fixed beam 2, and both sides of the fixed beam 2 can be provided with a functional box 3, and the lines and pipelines are located inside the functional box 3. A keel 1 is arranged on the top of the laboratory, and two fixed beams 2 are fixedly connected to the keel 1 . After setting in this way, the circuits and pipelines in the laboratory can be protected by the function box 3 to ensure that the circuits are neat and safe.

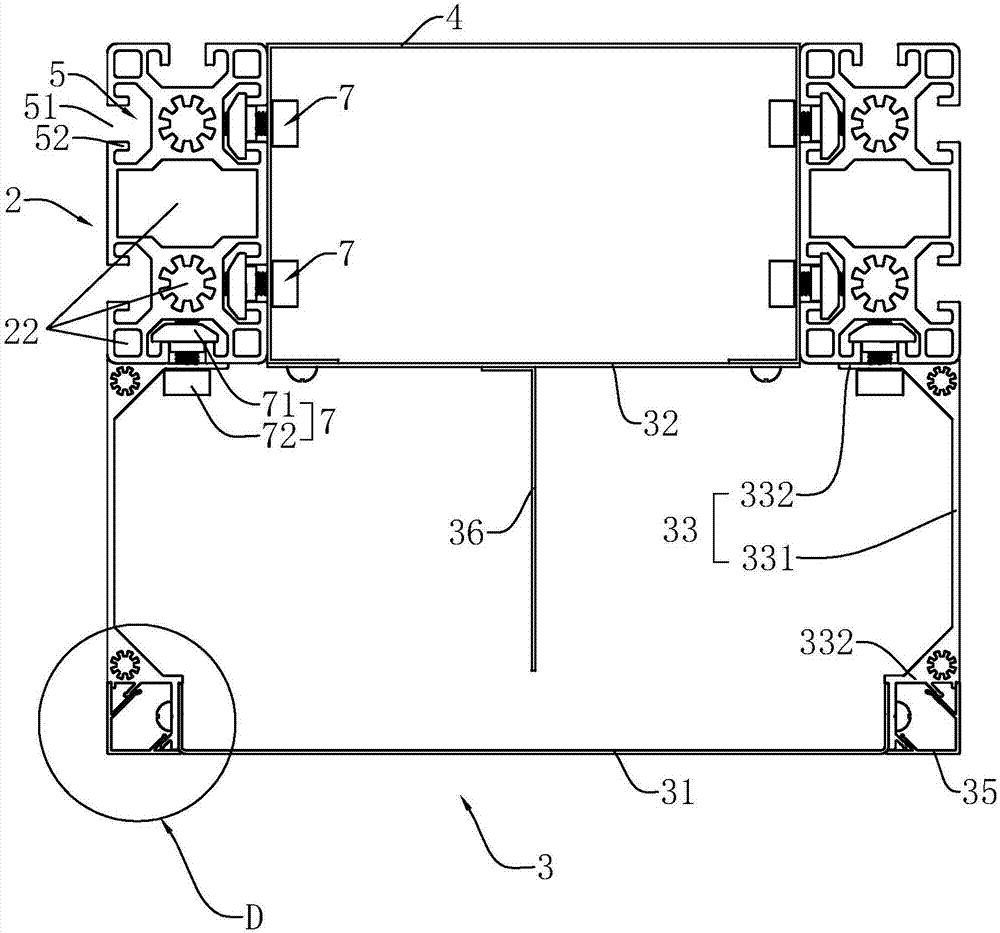

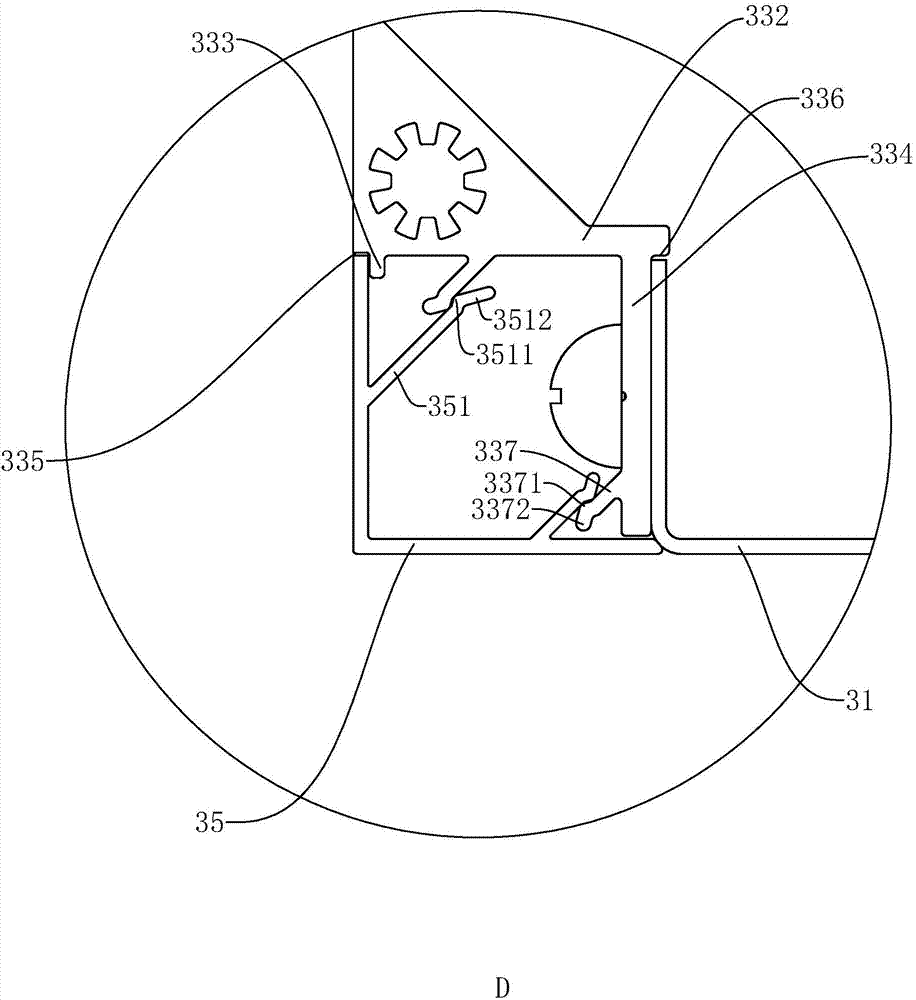

[0048] Such as figure 2 As shown, the section of the fixed beam 2 is rectangular, and the section of the fixed beam 2 is symmetrical to each other up and down. The section of the fixed beam 2 is provided with a spe...

Embodiment 2

[0070] The difference from the first embodiment is that the support 4 is a plurality of horizontally arranged boards, and the connection method between the support 4 and the fixed beam 2 and the functional box 3 is also different from that of the first embodiment.

[0071] Such as Figure 5 As shown, the upper surface and the lower surface of the support member 4 are provided with sinking grooves 6, and the upper and lower surfaces each contain four sinking grooves 6, and the sinking grooves 6 correspond to the special-shaped grooves 5 on the fixed beams 2 on the left and right sides respectively. , the support 4 is affixed to the fixed beam 2 through the second fastener 8; the front and rear sides of the support 4 are horizontally provided with special-shaped grooves 5, and the back plate 32 of the functional box 3 and the support 4 pass through the first fastening Firmware 7 is connected. The structure of the special-shaped groove 5 is as in the first embodiment.

[0072] ...

Embodiment 3

[0077] Such as figure 1 As shown, a suspension column with suspension function includes a keel 1, two fixed beams 2 and a plurality of functional boxes 3, the two fixed beams 2 are vertically arranged, the keel 1 is horizontally arranged on the top of the laboratory, and the two fixed beams 2 are fixed directly under the keel 1, the functional box 3 is hollow tubular, and the functional boxes 3 are spliced with each other up and down, the functional box 3 is fixedly connected with the fixed beam 2 through bolts, and the lines and pipelines are located inside the functional box 3 A support 4 is arranged between the two fixed beams 2 , and the support 4 is respectively fixed to the two fixed beams 2 and the functional box 3 .

[0078] The structure of fixed beam 2 and functional box 3 adopts the structure of fixed beam 2 and functional box 3 in embodiment one and embodiment two, and support member 4 can adopt the form of any one support member 4 in embodiment one or embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com