Device for realizing penetration of cable in pipe

A pipe-piercing device and cable technology, applied in cable installation, cable installation device, cable laying equipment, etc., can solve the problems of high labor cost, large manpower requirement, high labor intensity, etc., and achieve improved work efficiency and simple operation The effect of saving labor and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

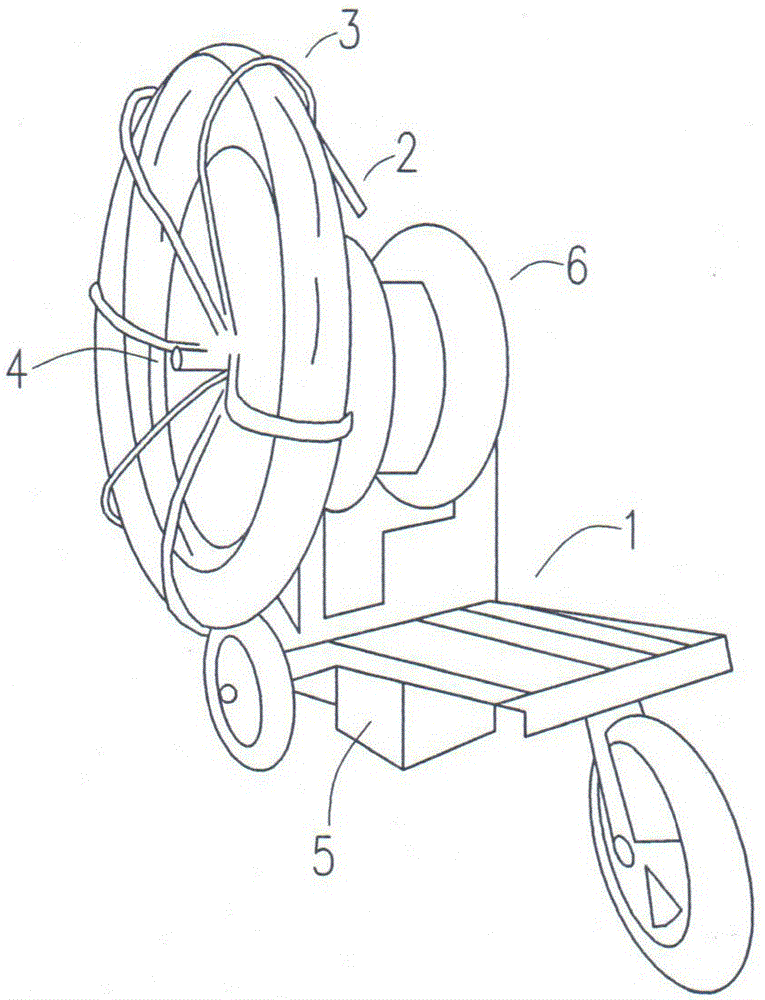

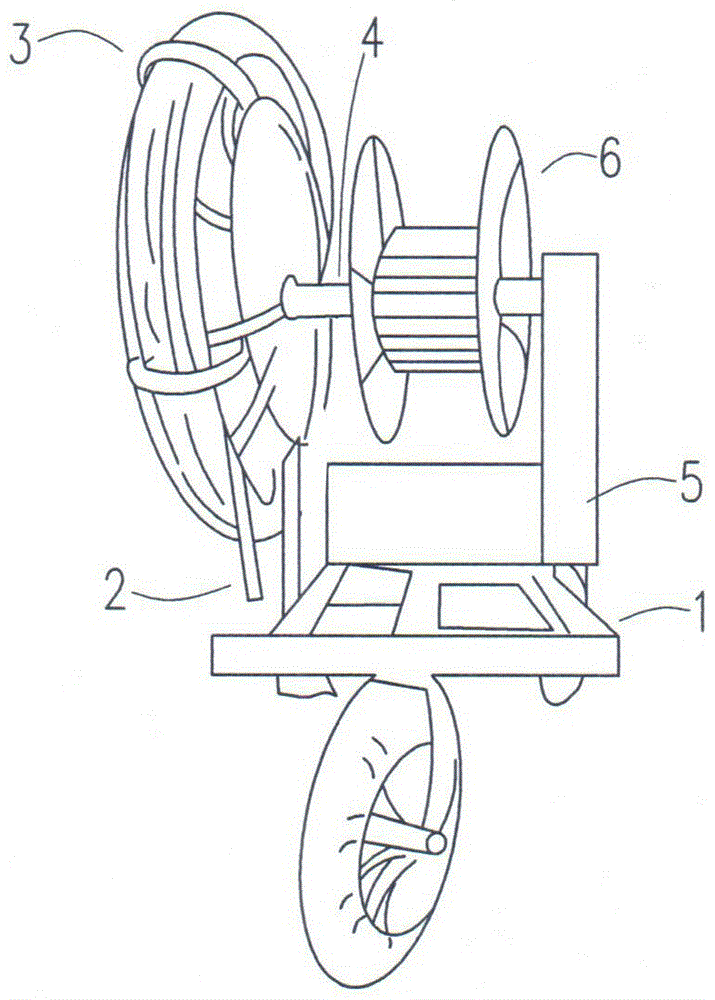

[0014] Such as figure 1 , figure 2 , image 3 As shown, an embodiment of the present invention includes a frame 1 with casters, a pipe-through drawbar 2, and a wheel disc 3, and the wheel disc 3 is arranged on the frame 1 through a rotating shaft 4, and the pipe-through drawbar 2 Wrapped in the wheel 3, it also includes a power mechanism 5 connected with the rotating shaft 4. Its principle is: by connecting power, the wheel 3 can rotate at a low speed, and during the rotation, the tube-through drawbar 2 can realize mechanized pushing or winding. Its operation only needs manual assistance, the operation is simple and labor-saving, and the labor cost is saved by about 40%.

[0015] One improvement is that the power mechanism 5 is an electric motor, and also includes a speed reducer matched with the electric motor. Power mechanism 5 also can be diesel engine, gasoline engine etc.

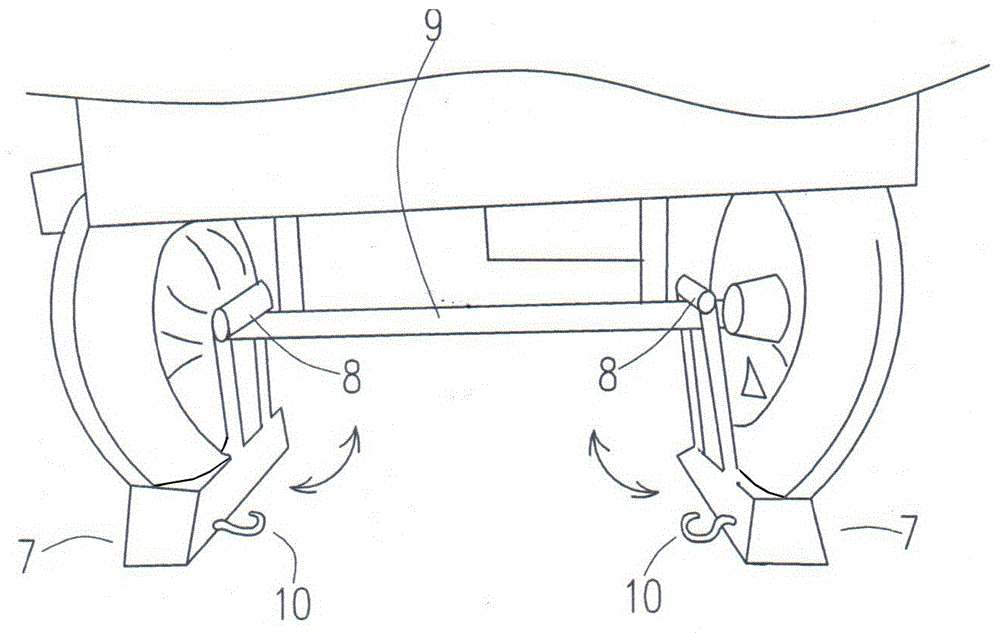

[0016] Such as figure 1 , figure 2 As shown, another improvement is to further include a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com