A Method for Identifying Critical Damage in Plastic Compression Forming

A compression forming and identification method technology, applied in design optimization/simulation, special data processing applications, etc., can solve the problems of compression plastic forming calculation and analysis, large critical damage strain error, and less critical damage research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

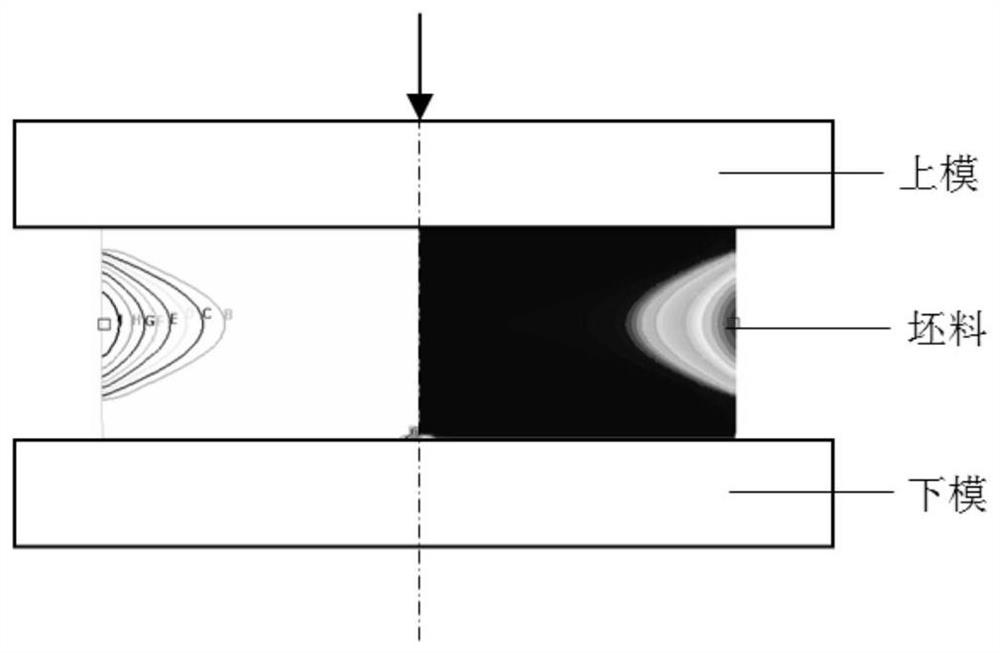

[0022] Isothermal and constant strain plastic compression forming of pure copper such as figure 1 As shown, the original size of the blank is 8mm in diameter and 12mm in height, respectively at a deformation temperature of 800°C and a strain rate of 0.001s -1 、0.01s -1 , 0.1s -1 、1s -1 Under the condition of The parameters of the function are set to perform plastic compression deformation on the blank.

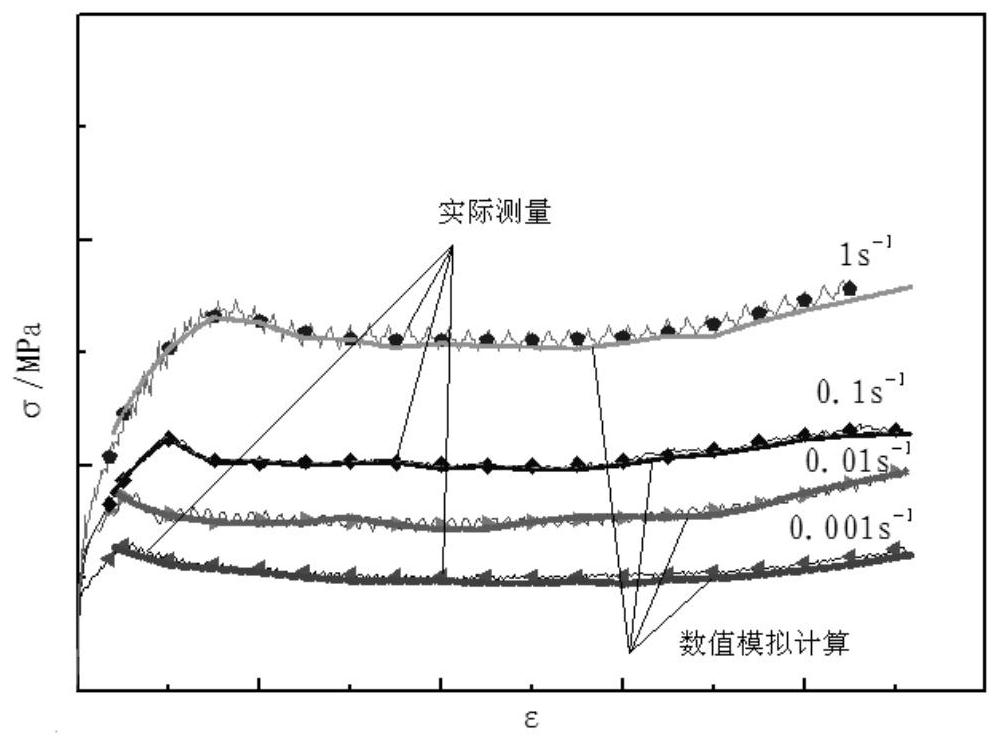

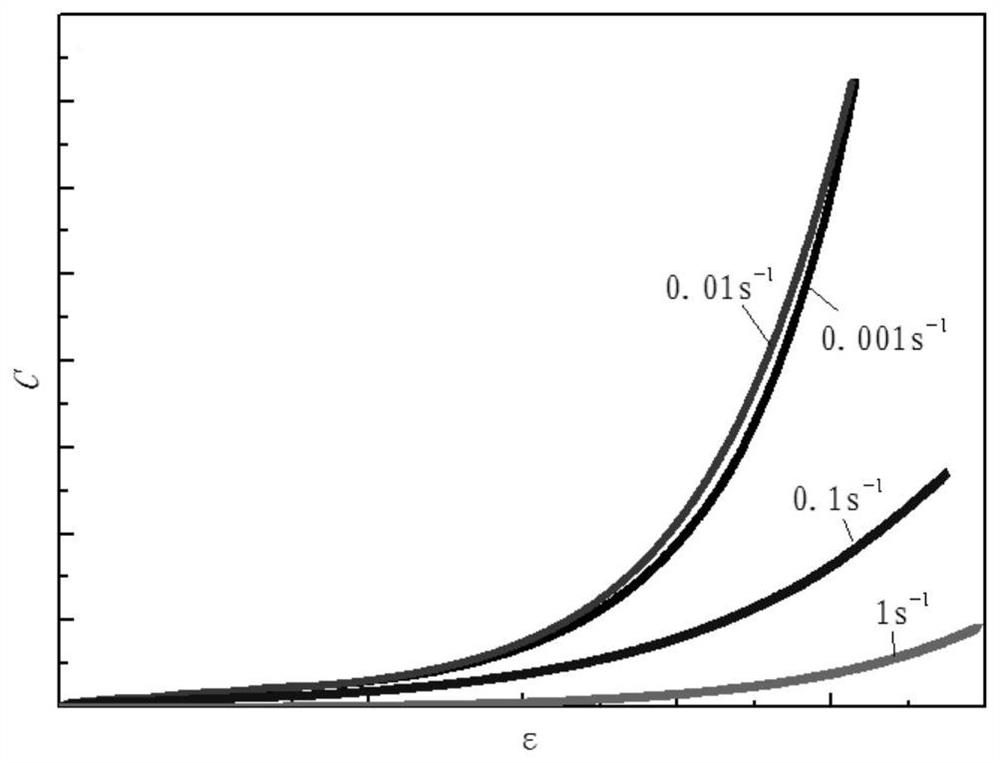

[0023] figure 2 The equivalent stress and strain curves calculated by numerical simulation and actual measurement are basically consistent, indicating that the set movement speed of the upper mold is reliable. On this basis, extract the internal stress during the blank deformation process, such as the principal stress, etc., using Calculate the cumulative damage, and obtain the relationship curve between cumulative damage and strain as follows: image 3 , and establish the piecewise function relationship between the polynomial and exponential terms of cumulative dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com