Low pressure pressure preparation method of alumina ceramic fiber/particle reinforced metal matrix composites

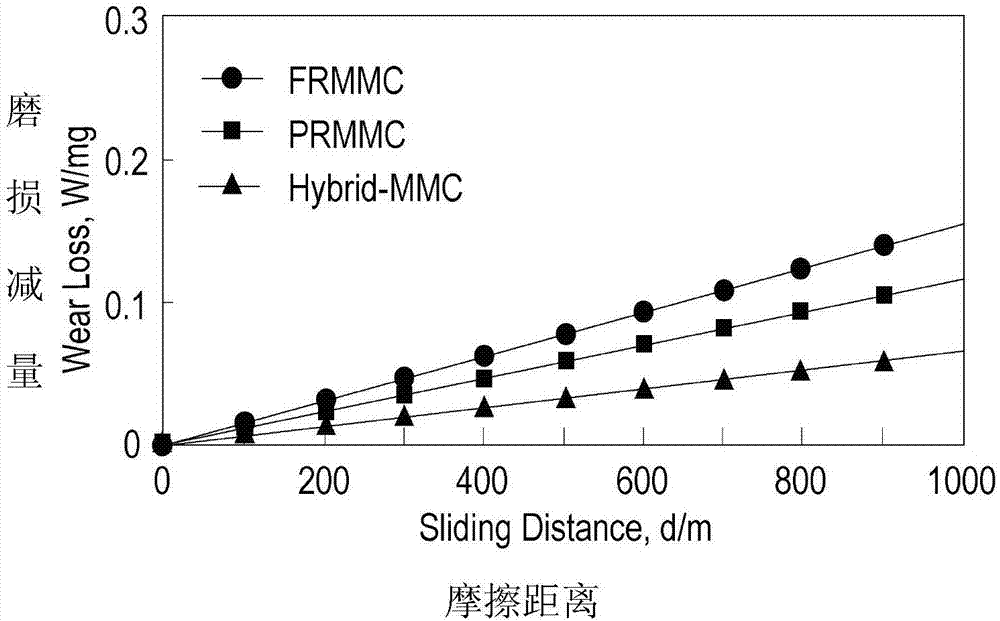

A technology of alumina ceramics and composite materials, which is applied in the field of low-pressure pressurized preparation of alumina ceramic fiber/particle reinforced metal matrix composites, achieving high efficiency, low cost, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Al of this embodiment 2 O 3 The ceramic fiber / particle reinforced metal matrix composite material was prepared as follows: 2g of binder PEG was added to a beaker filled with 20ml of ethanol, and when the test tube size was 15mm in diameter to make a cylindrical material with a height of 1cm, more than 2g The amount of addition will cause volume expansion when the embryo body is formed. When the addition amount is less than 2g, the bonding effect cannot be achieved effectively.

[0024] After the complete dissolution, take the volume fraction of 12.5vol.% Al 2 O 3 Fiber, volume fraction 7.5vol.%Al 2 O 3 Particles, 0.8 g of Al particles were put into a beaker and stirred. Put the mixed sample into a test tube with a diameter of 15mm, compress both ends of the test tube, compress it into a cylinder with a height of 10mm, and put it into an electric furnace and heat it to 773K for 1 hour to make Al. 2 O 3 Ceramic body.

[0025] Al-based alloy is used as base materi...

Embodiment 2

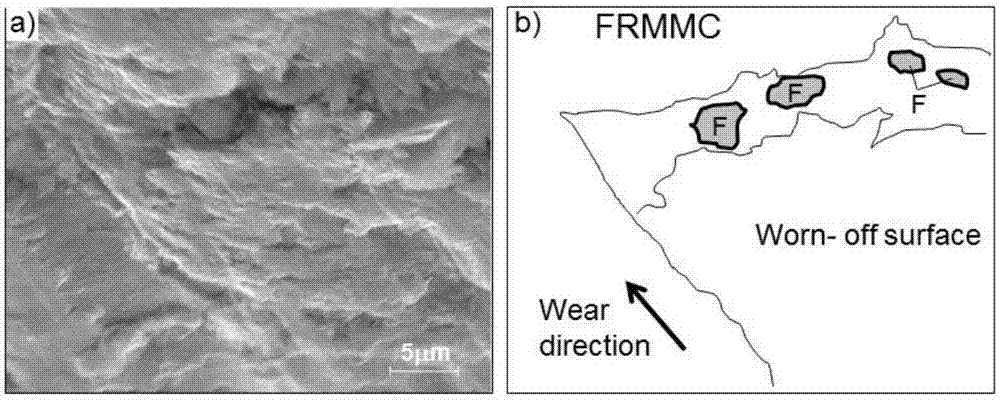

[0028] The difference between this embodiment and Embodiment 1 is that the composition of the ceramic body is different, and this embodiment only uses Al 2 O 3 Fiber-reinforced metal matrix composites. Add 2g of adhesive PEG to the beaker containing 20ml of ethanol, and after it is completely dissolved, take the volume fraction of Al 2 O 3 Fiber 20vol.% is placed in a beaker and stirred. Put the mixed sample into a test tube with a diameter of 15mm, compress both ends of the test tube, compress it into a cylinder with a height of 10mm, and put it into an electric furnace and heat it to 773K for 1 hour to make a ceramic green body. Using Al-based alloy as the base material, the metal matrix composite material is made by compounding the ceramic body and the alloy through a high-frequency heater.

Embodiment 3

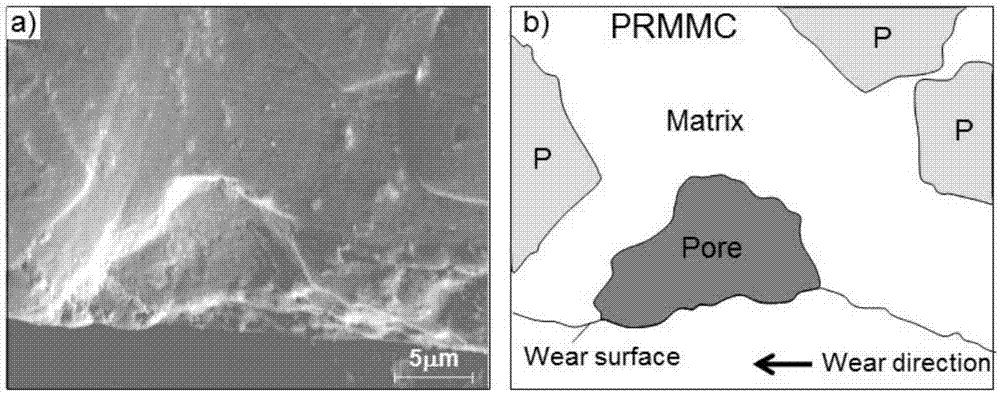

[0030] The difference between this embodiment and Embodiment 1 is that the composition of the ceramic body is different. In this embodiment, Al is used. 2 O 3 Particle Reinforced Metal Matrix Composites. Add 2g of adhesive PEG to a beaker containing 20ml of ethanol, and after it is completely dissolved, take a volume fraction of 20vol.% Al 2 O 3 The particles are placed in a beaker and stirred. Put the mixed sample into a test tube with a diameter of 15mm, compress both ends of the test tube, compress it into a cylinder with a height of 10mm, and put it into an electric furnace and heat it to 773K for 1 hour to make a ceramic green body. Using Al-based alloy as the base material, the metal matrix composite material is made by compounding the ceramic body and the alloy through a high-frequency heater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com