Device for treating, by heat tempering, a metal element of the tube or bar type having arched portions

A technology for heat treatment equipment and metal components, applied in heat treatment equipment, heat treatment furnaces, quenching devices, etc., can solve problems such as the complexity limitation of metal components, and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

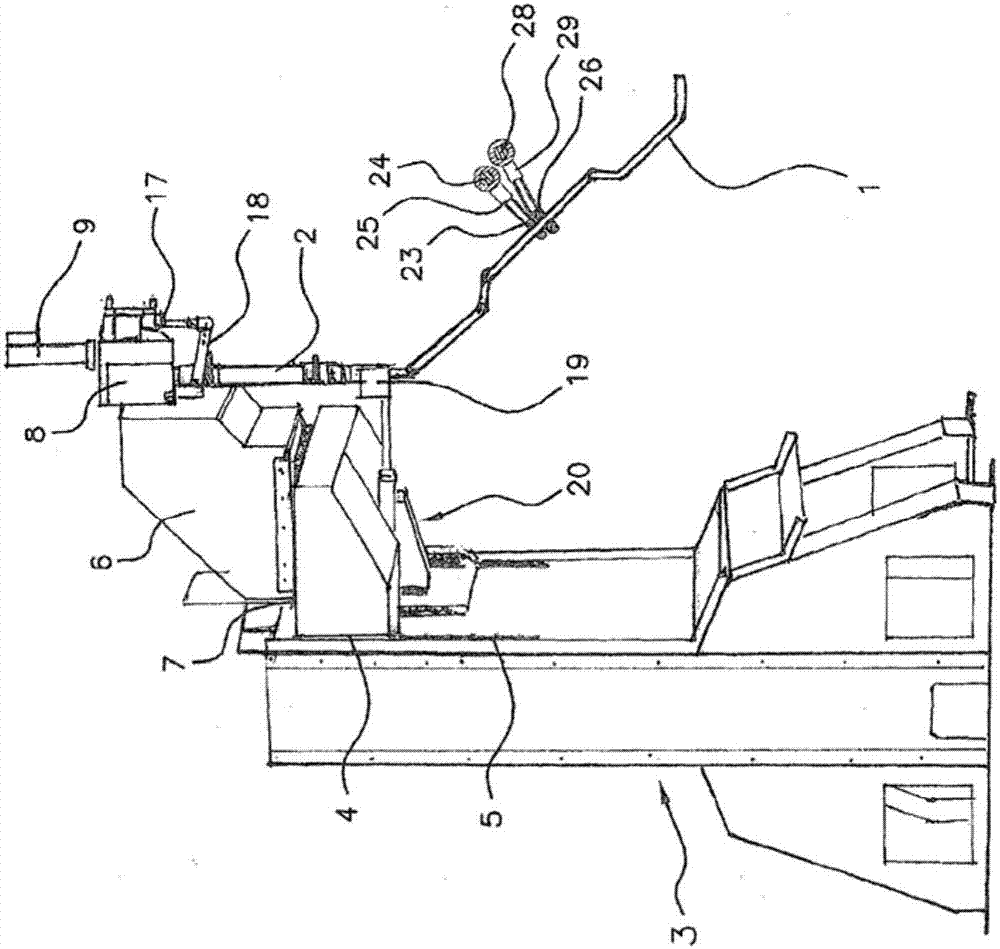

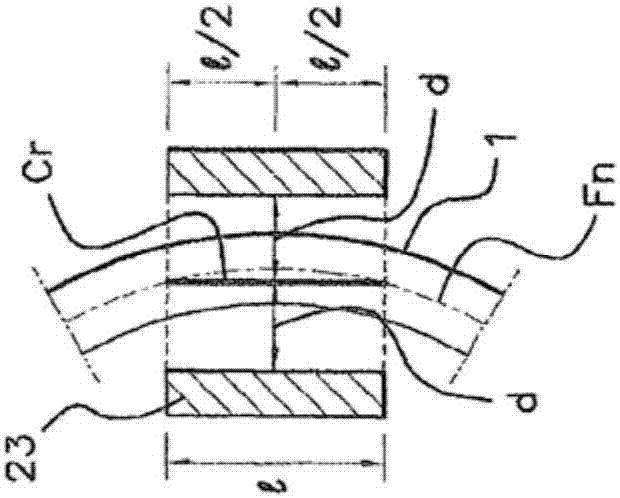

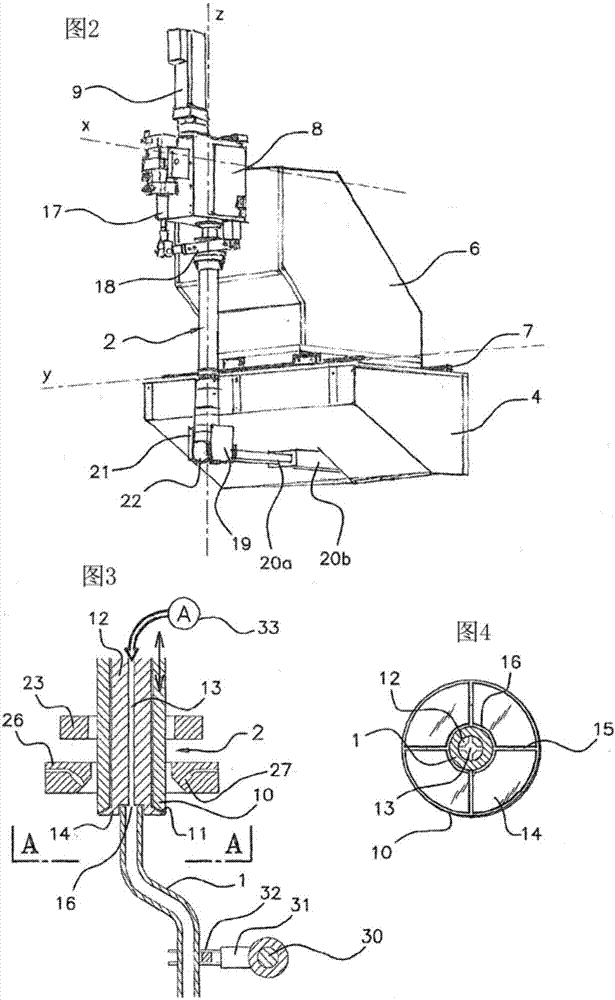

[0050] The treatment plant according to the invention shown in the figures comprises a plant for the thermal hardening of rod-shaped or tubular metal elements, for example suspension elements of motor vehicles, which may in particular include: the torsion bar 1 shown in the figures.

[0051] The processing equipment first includes:

[0052] The means 2 for fixing the metal element 1, comprising a clamp, arranged in the vicinity of said upper end section of said metal element, so that the metal element is freely suspended below said clamp,

[0053] Means for moving the gripper 2, adapted to translate the gripper on the one hand along a vertical axis (z) and a horizontal axis (y) and on the other hand around a vertical axis (z) and a horizontal plane perpendicular to the plane (y, z) Axis (x) rotates the fixture.

[0054] Firstly, the clamp consists of a tubular clamp 2 of the free-scissors type, comprising a rotary part separated along several generatrix points, so that by its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com