Anti-drop structure of gear motor

A kind of anti-separation structure, geared motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of geared motor damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

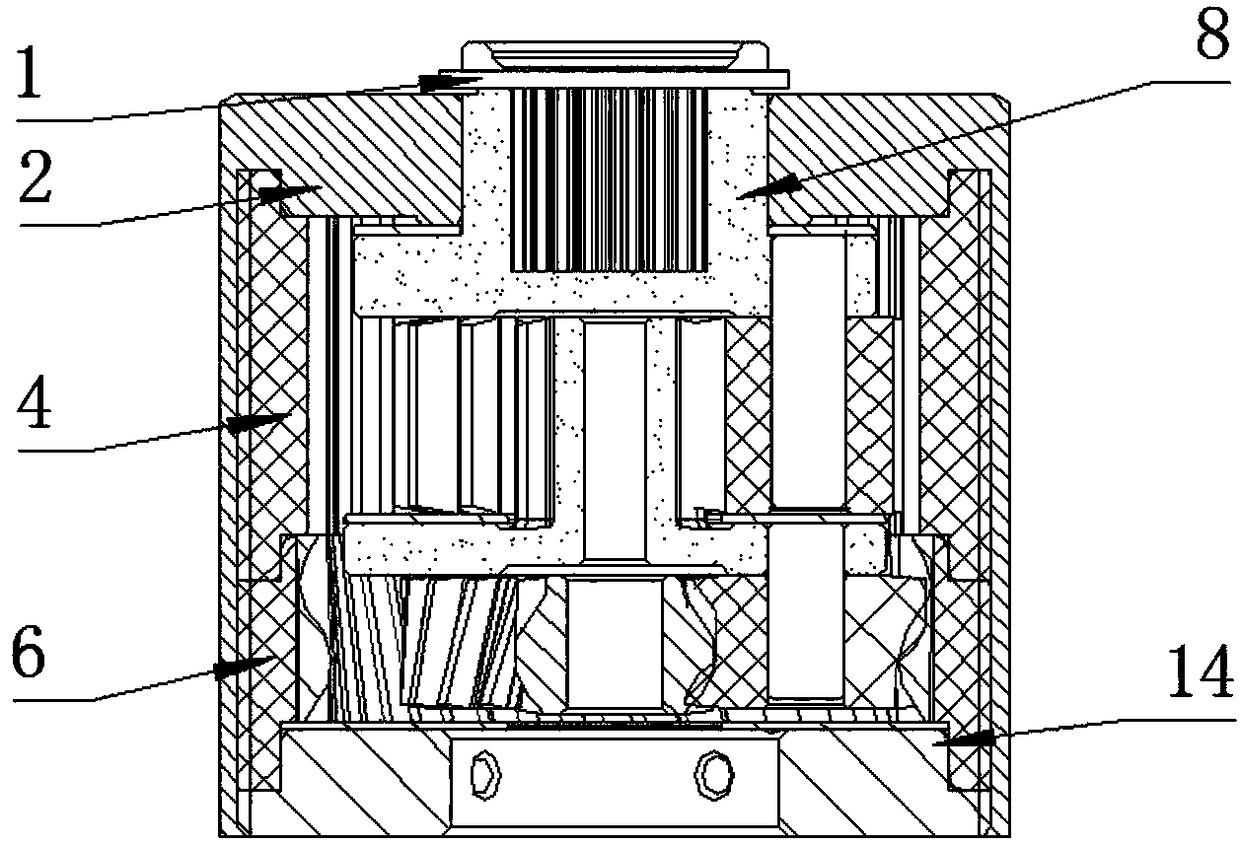

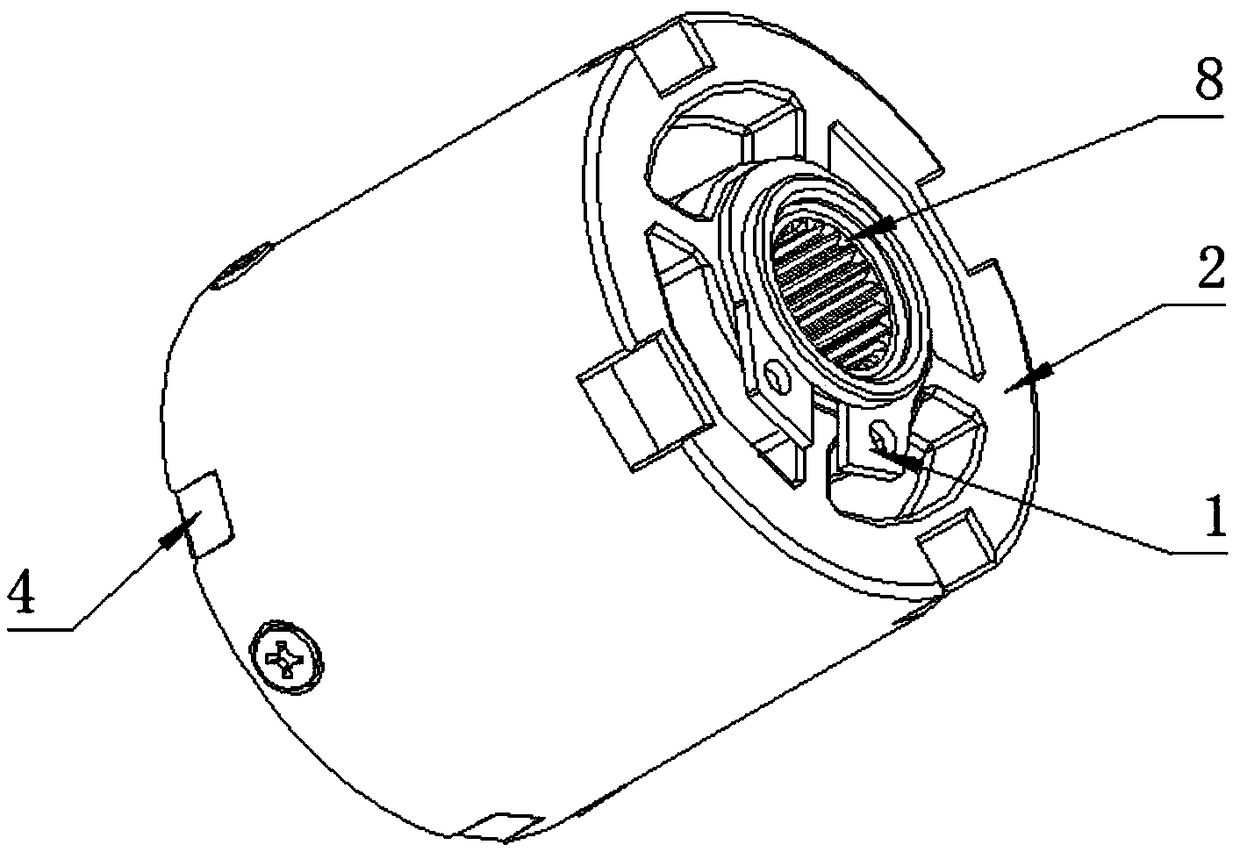

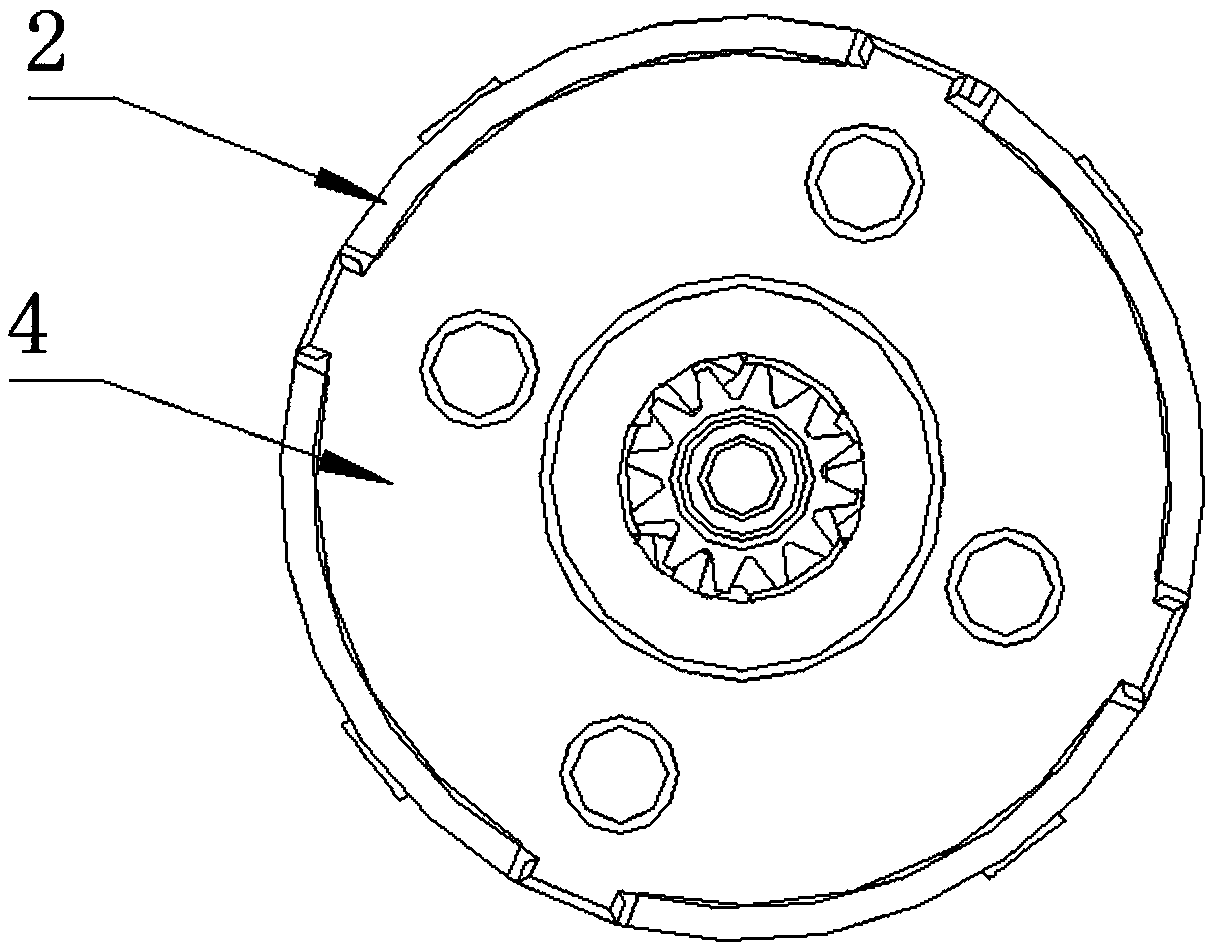

[0020] Please refer to Figure 1-Figure 5 , in an embodiment of the present application, the anti-off structure of the deceleration motor includes: a housing 2, a rear end cover 14, a secondary spur gear 4, a primary helical gear 6, an output planetary carrier 8 and a shaft retaining ring 1 . Wherein the rear end cover 14 is connected to the shell 2 . The secondary spur gear 4 is connected to the inner wall of the casing 2 . The primary helical gear 6 meshes with the secondary spur gear 4 . The output planetary carrier 8 is arranged inside the casing 2 . The shaft retaining ring 1 is connected to the output planet carrier 8 , and the shaft retaining ring 1 is arranged outside the output planet carrier 8 and inside the casing 2 . The output planetary carrier is connected to the outer casing through a shaft retaining ring, which can effectively control the external axial force received by the output planetary carrier, which can not only prevent falling off, but also protect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com