Glass glue caulking gun with roll ball

A technology of glue-pressing glue guns and glass, which is applied to the device and coating of the surface coating liquid, which can solve the problems of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

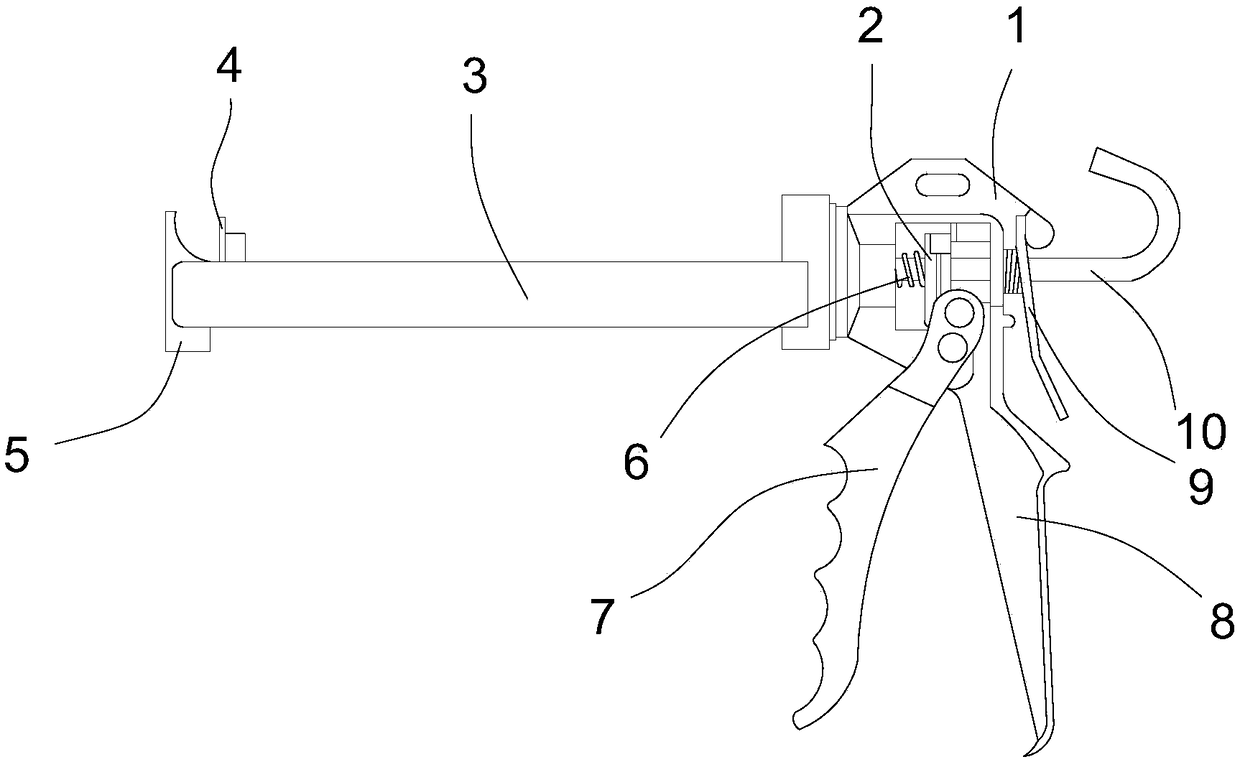

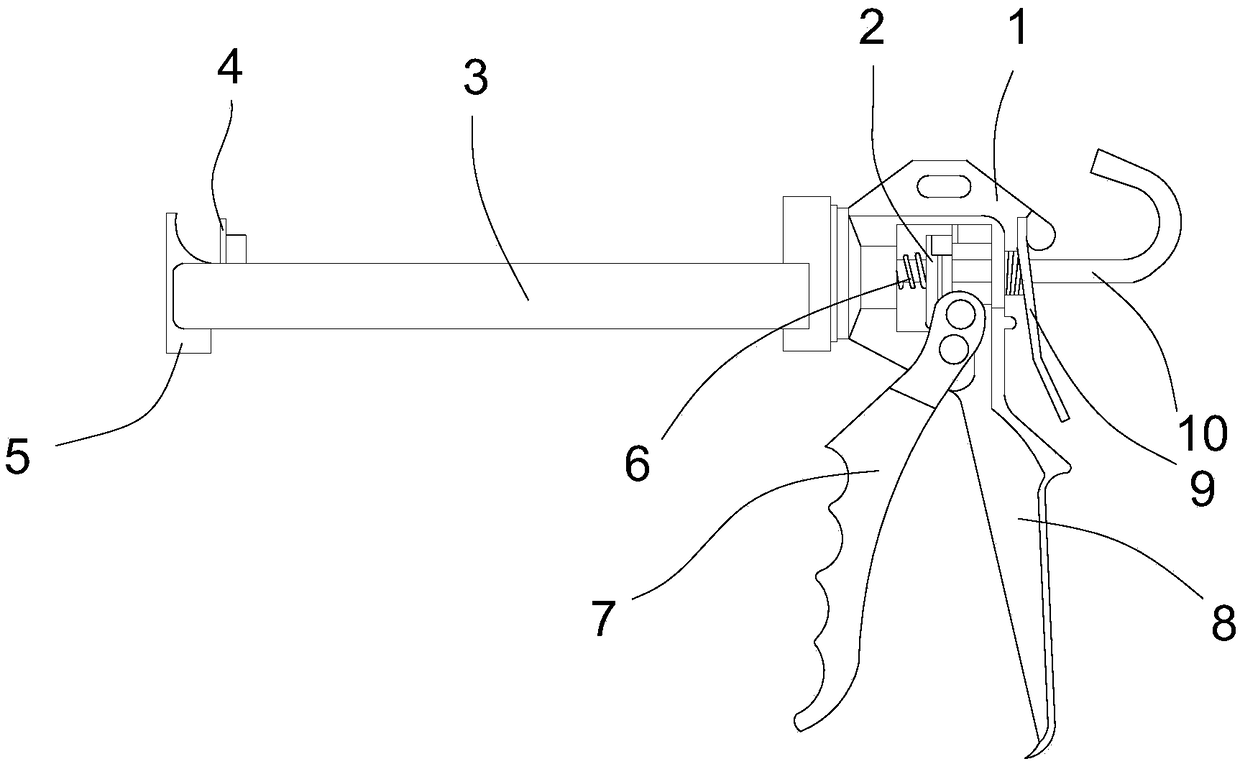

[0021] Such as figure 1 , 2 Shown is an embodiment of a glass glue glue gun with balls in the present invention, the glass glue glue gun includes a gun body bracket 1, and a push rod 10 is movably arranged on the gun body bracket 1, and the push rod 10 is set with a pushing part 2, and the gun body bracket 1 is hinged with a pulling part 7, and the pulling part 7 is connected with the pushing part 2, and the front end of the gun body bracket 1 is provided with a glass The rubber sheath 3 of the rubber cartridge, the front end of the push rod 10 extends into the rubber sheath 3, and the front end of the push rod 10 is provided with a rubber pusher that contacts the piston part of the glass rubber cartridge. disc 4, the outer peripheral surface of the rubber pushing disc 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com