Automobile part gluing device with collecting function

A technology of auto parts and gluing device, which is applied to the surface coating liquid device, coating, etc., can solve the problems of dripping glue polluting the environment, extruding glue is not clean, and gluing quality is low, so as to improve the gluing quality. The quality of glue, the height and width of the glue are uniform, and the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

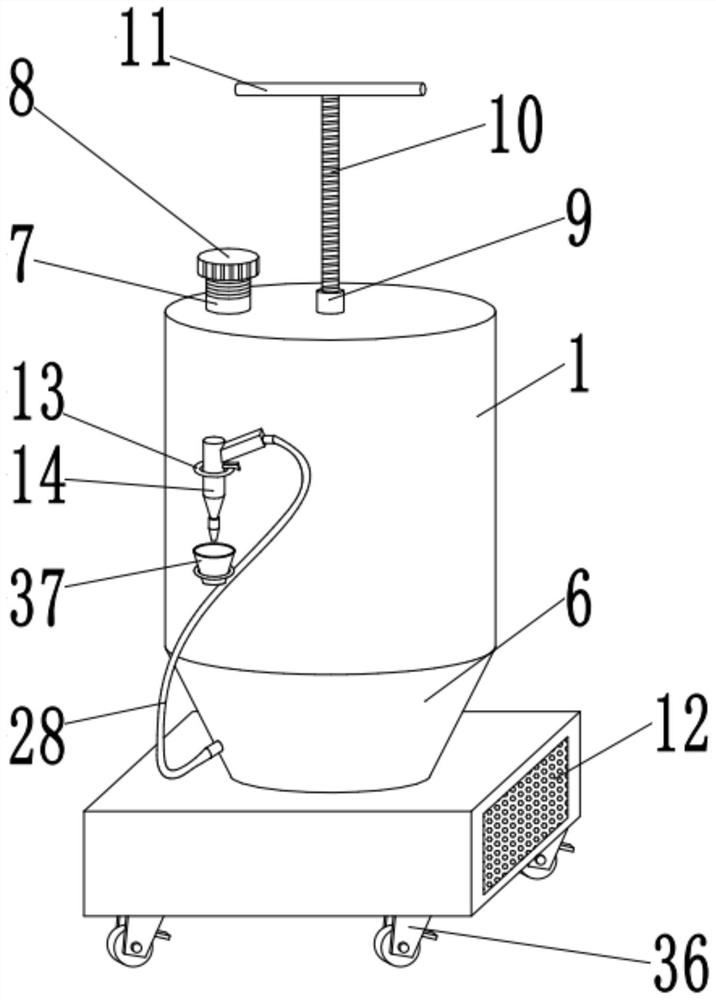

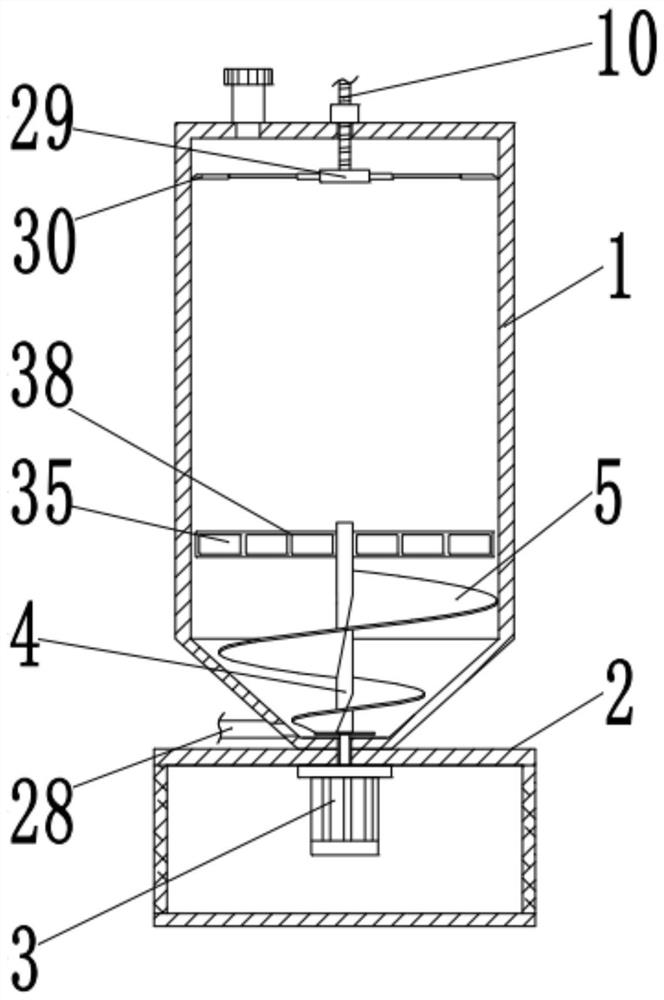

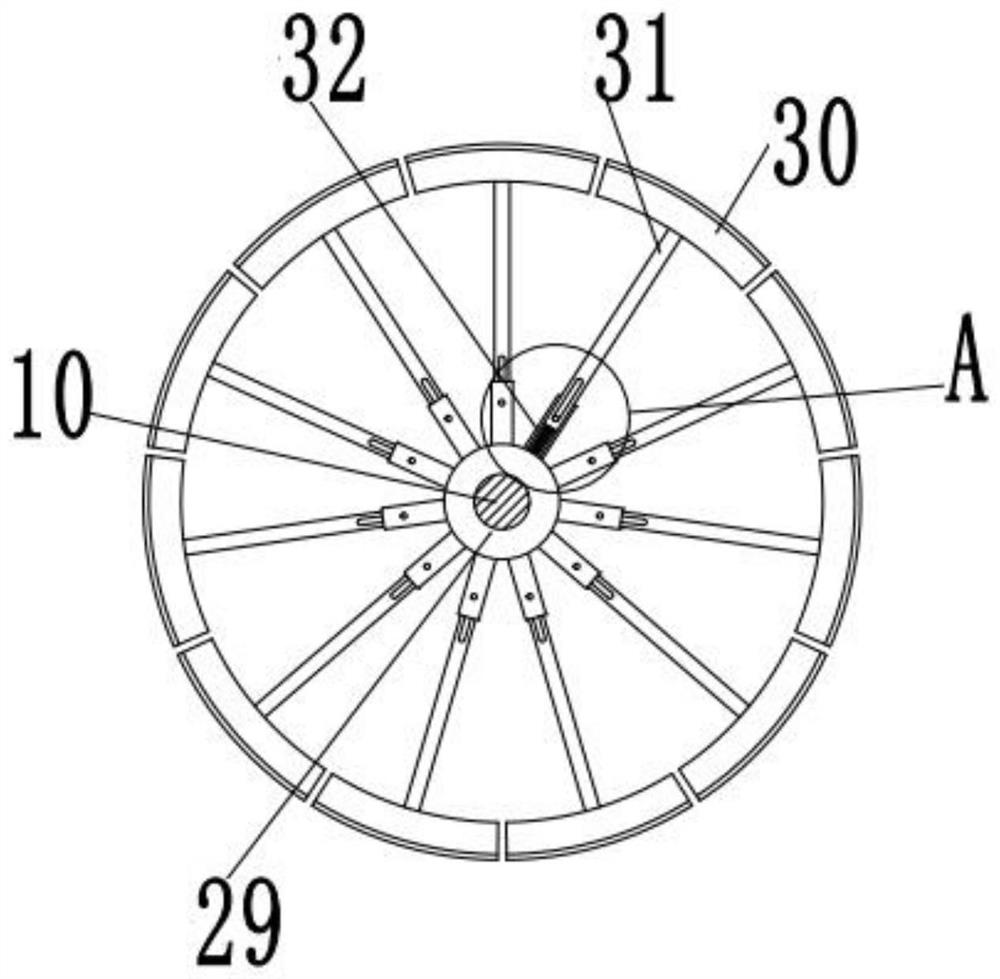

[0032] A gluing device for auto parts with a collection function, including a glue barrel 1, the glue to be glued is poured into the glue barrel 1, the bottom of the glue barrel 1 is welded with a conical bottom 6, and the conical bottom 6 is used to gather The role of the glue, and then make the glue inside the glue barrel 1 not produce too much waste, the bottom outer wall of the conical bottom 6 is welded with the bottom shell 2, and the top inner wall of the bottom shell 2 is connected with the reduction motor 3 through bolts, and the reduction motor 3 The model is CH-28, one end of the output shaft of the deceleration motor 3 runs through the top inner wall of the bottom shell 2 and is connected with the rotating shaft 4 through a spline, and the outer wall of the rotating shaft 4 is welded with a conical auger plate 5, the structure of the conical auger plate 5 It is an inverted cone-shaped structure with a large top and a small bottom. The geared motor 3 is used to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com