Glue pressing gun with improved pushing component

A technology of glue gun and glue glue gun, which is applied in the directions of devices and coatings that apply liquid to the surface, can solve the problems of displacement, poor driving effect, collision, etc., and achieve the effect of firm contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

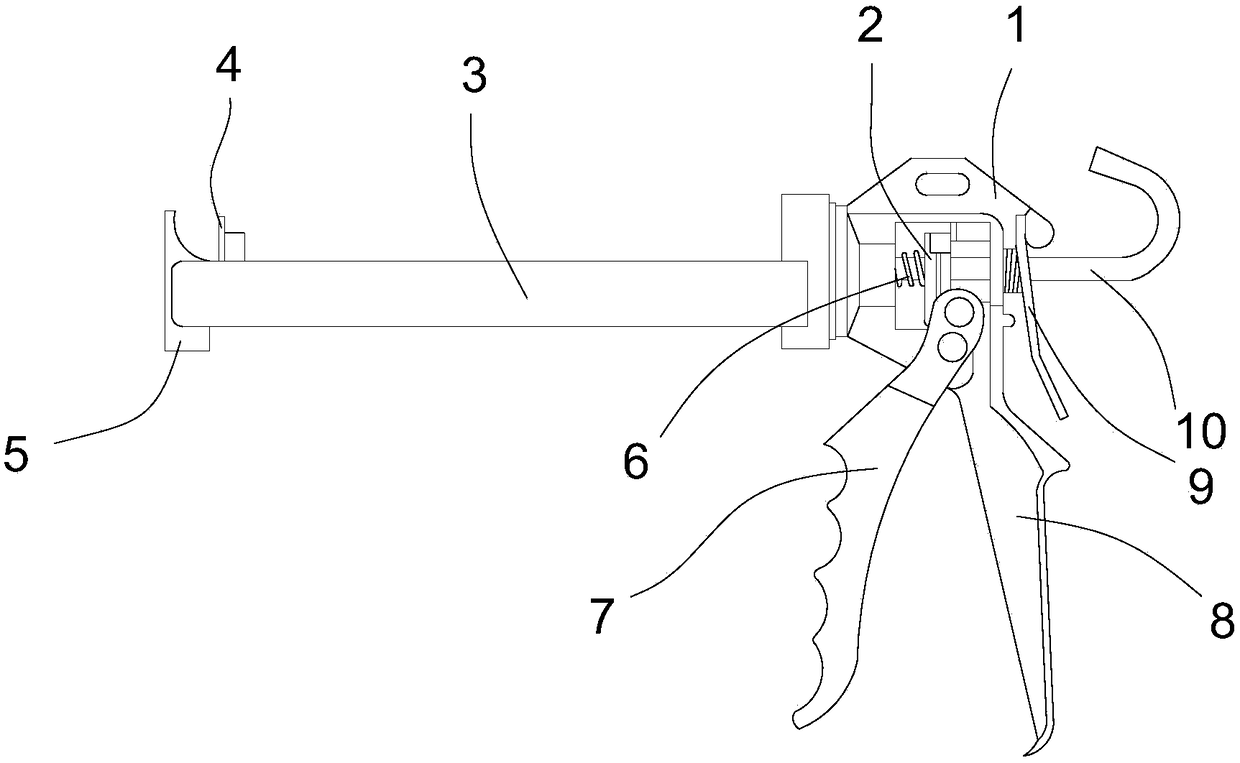

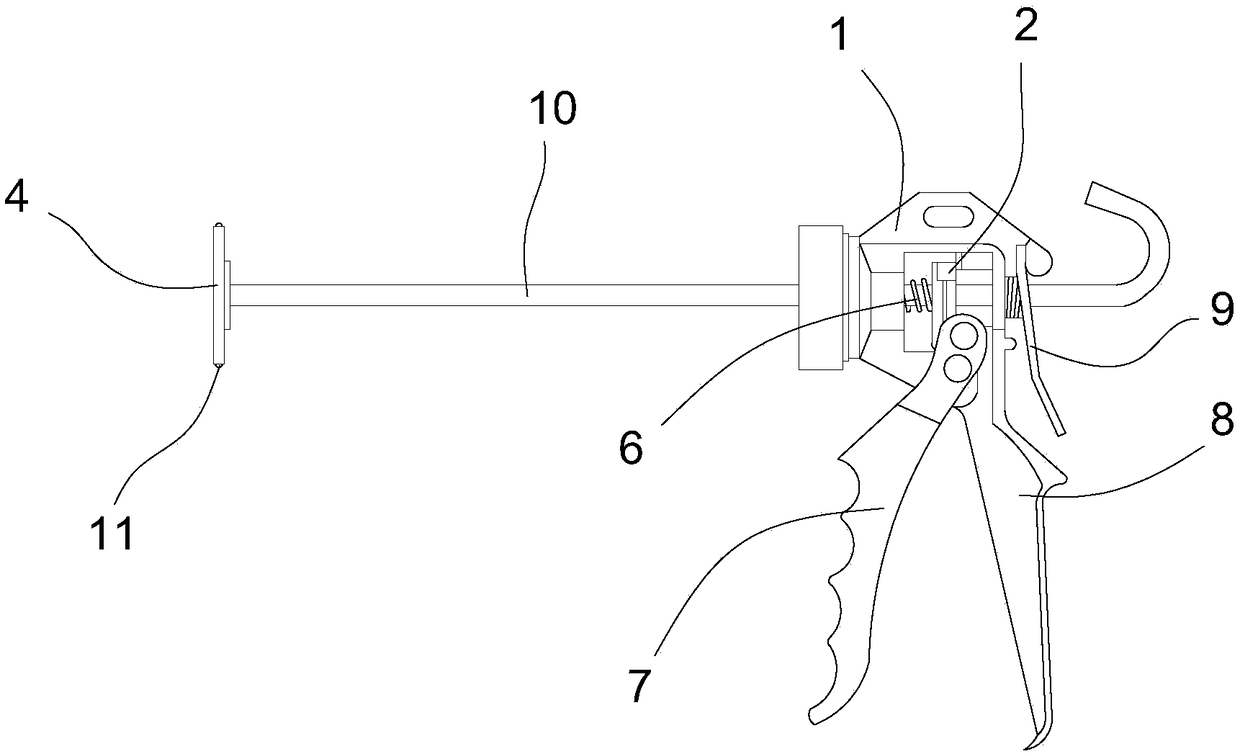

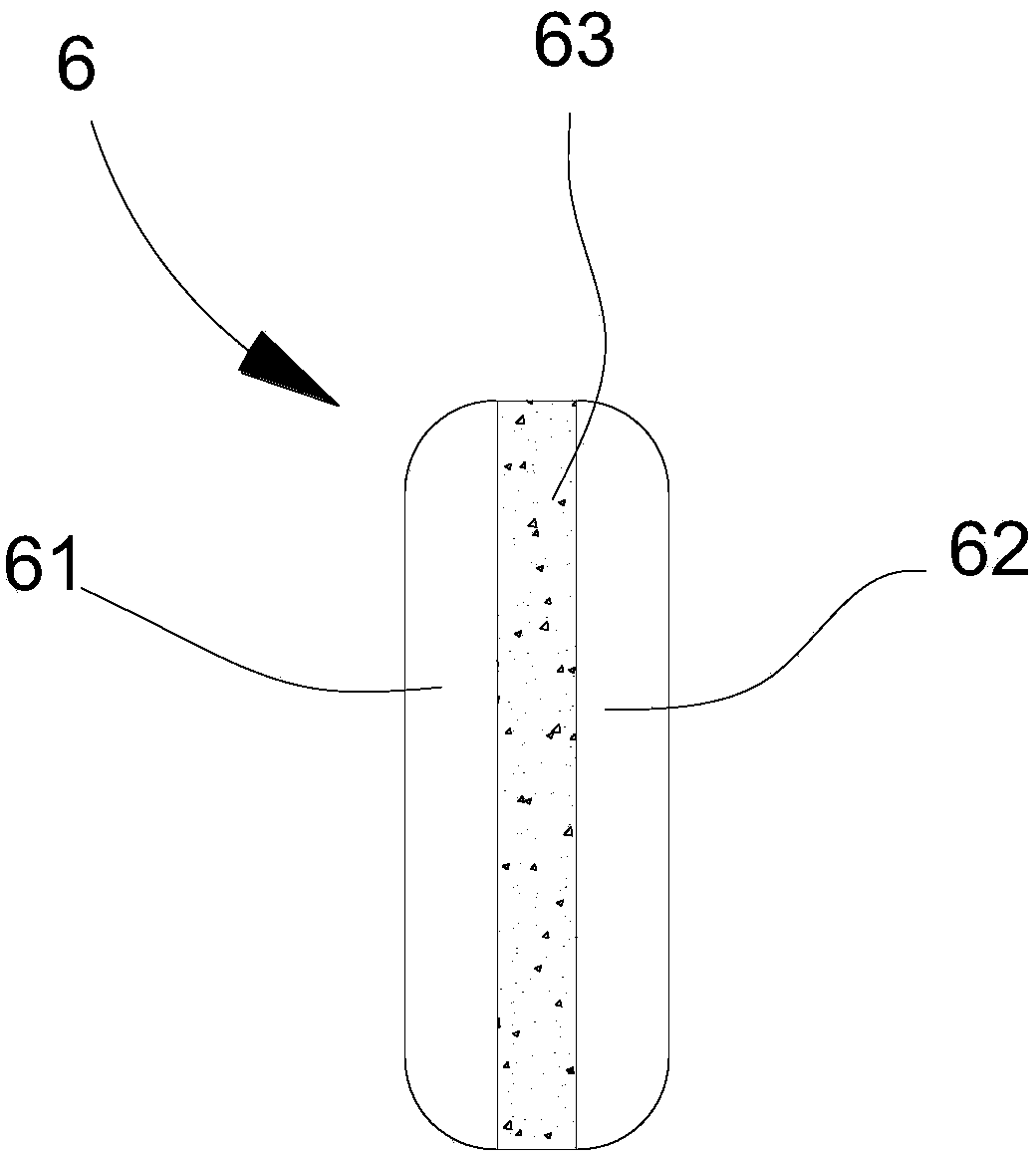

[0022] Such as figure 1 , 2 Shown is an embodiment of a caulking gun with improved push parts of the present invention, the glass glue caulking gun includes a gun body bracket 1, a push rod 10 is movably arranged on the gun body bracket 1, and the push rod 10 is set with a pushing part 2, and the gun body bracket 1 is hinged with a pulling part 7, and the pulling part 7 is connected with the pushing part 2, and the front end of the gun body bracket 1 is provided with a glass The rubber sheath 3 of the rubber cartridge, the front end of the push rod 10 extends into the rubber sheath 3, and the front end of the push rod 10 is provided with a rubber pusher that contacts the piston part of the glass rubber cartridge. The disc 4, the outer peripheral surface of the rubber pushing disc 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com