Clamping device for pipe beveling machine

A technology of clamping device and beveling machine, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of unsuitable pipes of various sizes, thick overall thickness, and unfavorable transportation management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

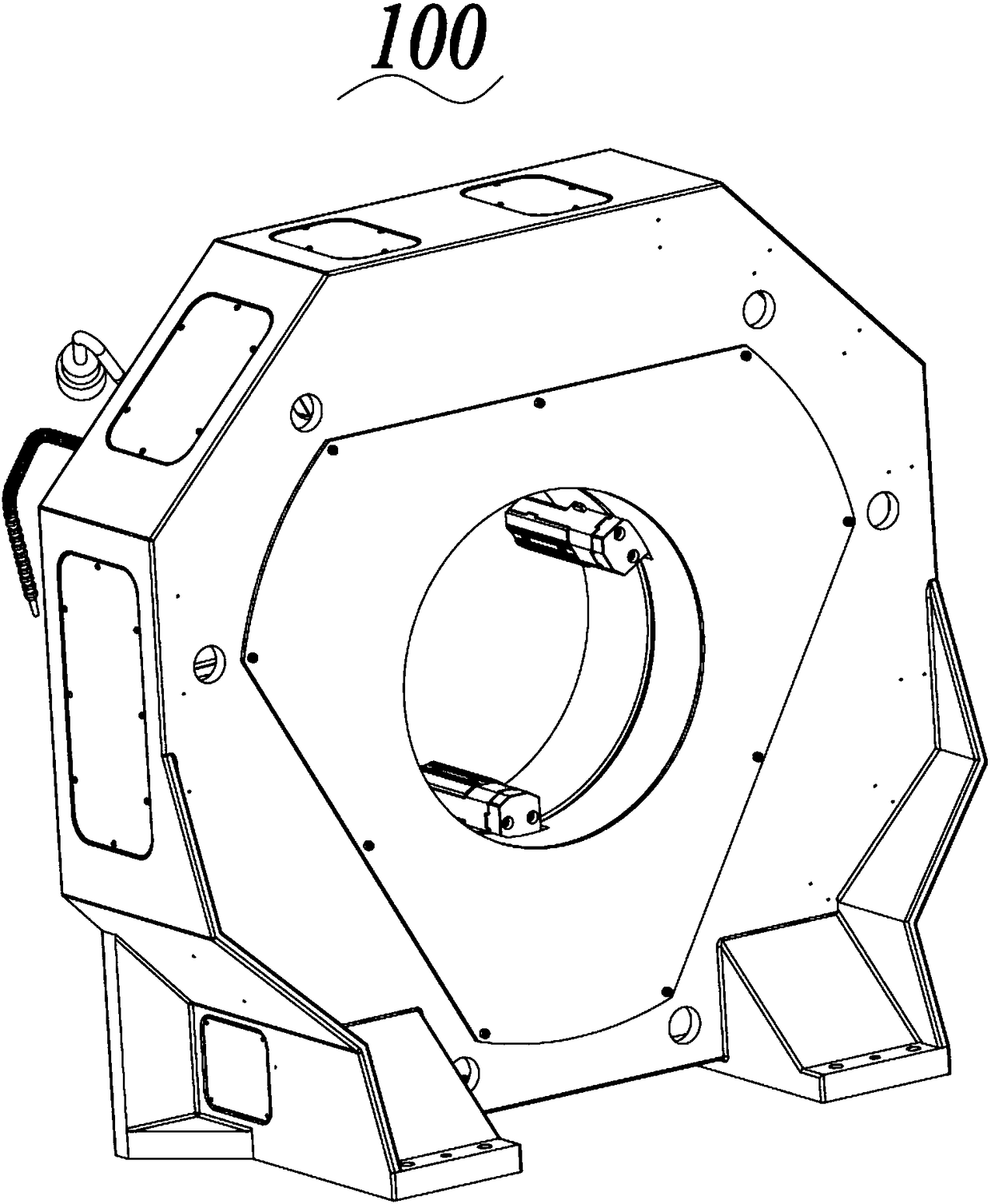

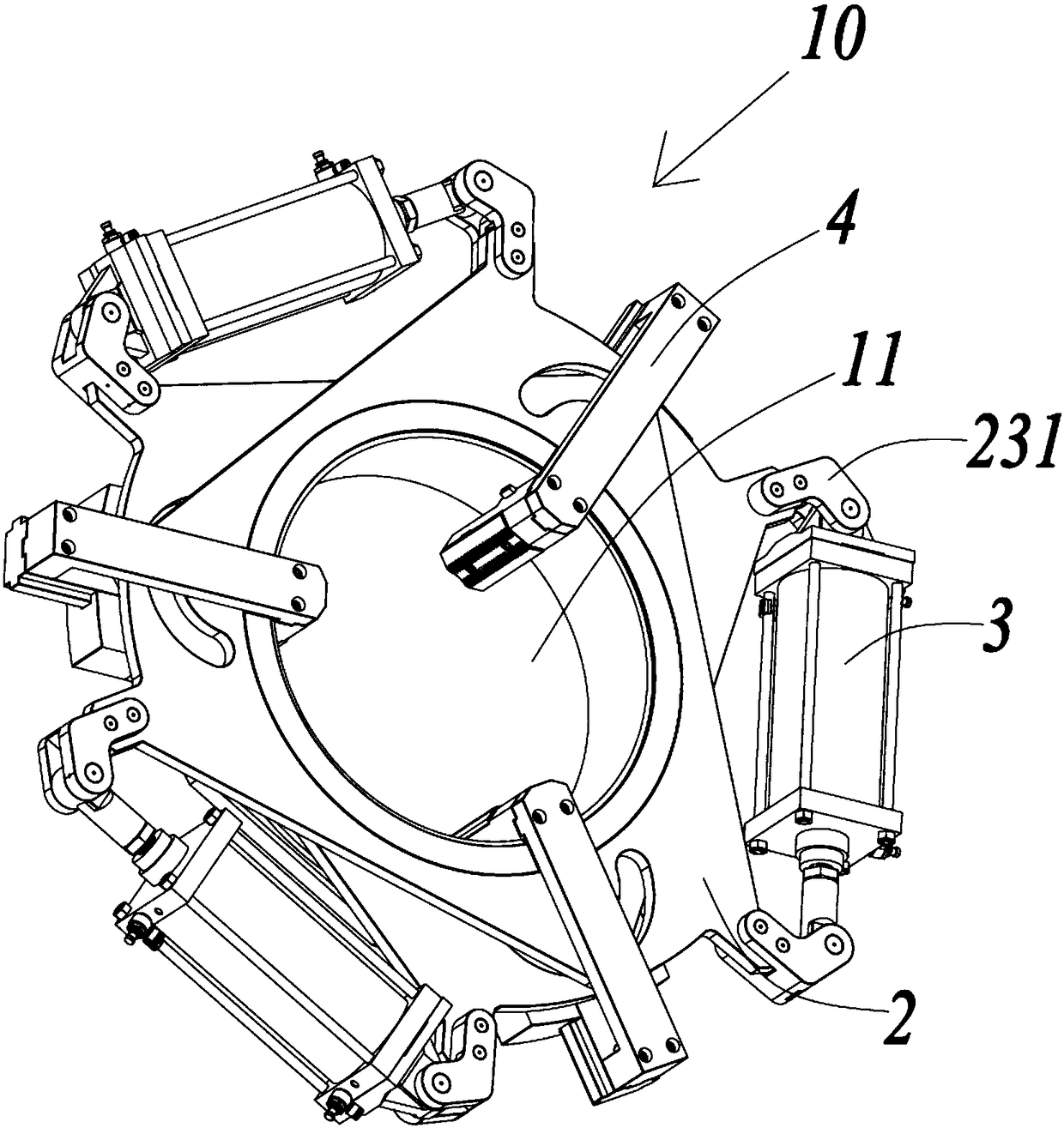

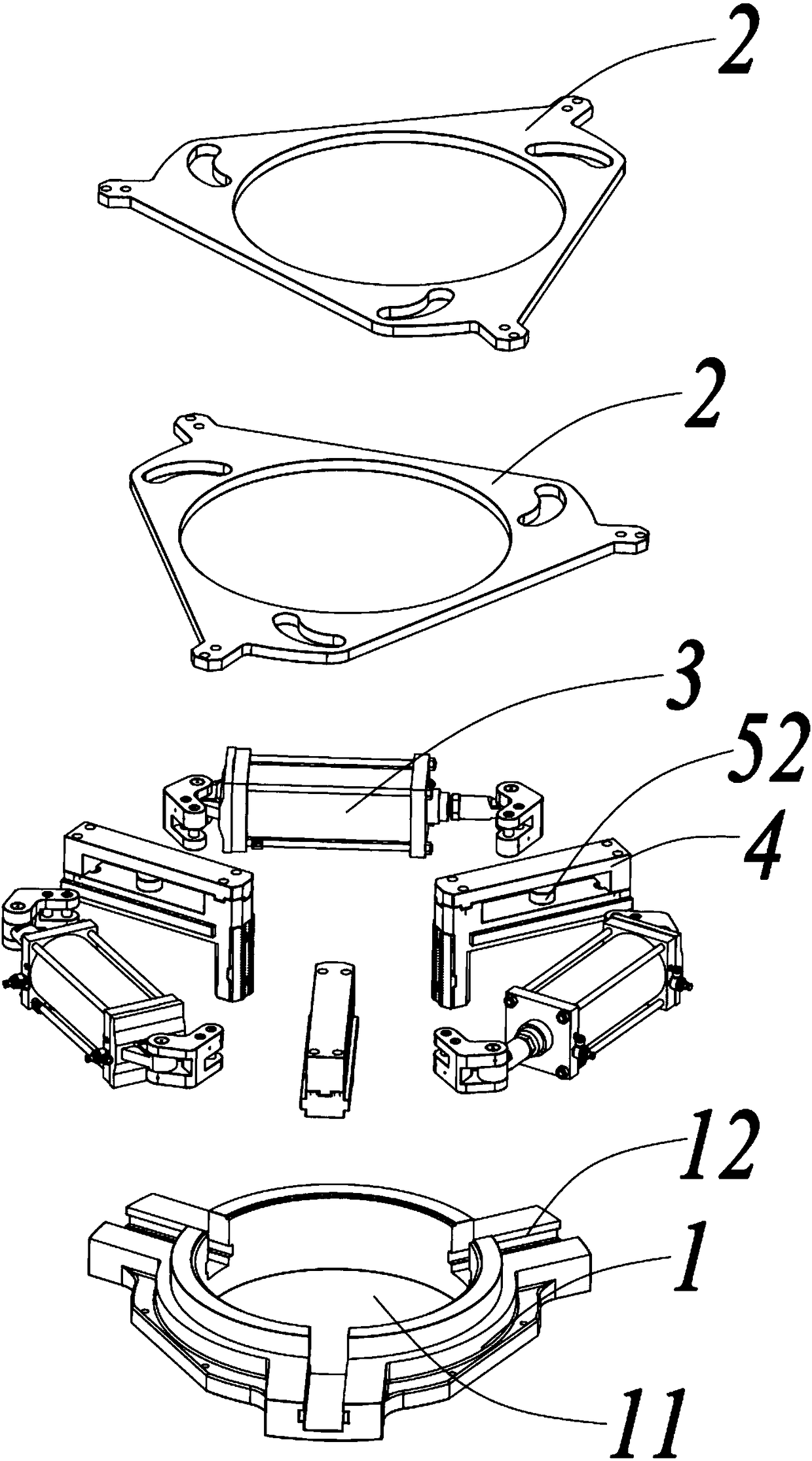

[0023] Such as Figure 1 to Figure 7 As shown, a clamping device 10 for a pipe beveling machine 100 of the present invention is mainly applicable to a moving head frame of a pipe beveling machine 100 for clamping the pipe. The pipe beveling machine 100 usually also includes an advancing and retreating knife mechanism, which is used for notching the pipe or cutting the pipe.

[0024] The clamping device 10 can be set to one or two, when the clamping device 10 is set to one, after one pipe is cut into two, one pipe is continued to be clamped by the clamping device 10, and the other The first pipe then falls; when tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap