Self-suction pump pressure packing bottle discharging pipe

A discharge tube and packaging bottle technology, applied in the field of packaging, can solve the problem that the discharge tube cannot meet the needs of wall hanging, and achieve the effects of being conducive to wall hanging of paste, satisfying the design, and convenient for daily use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

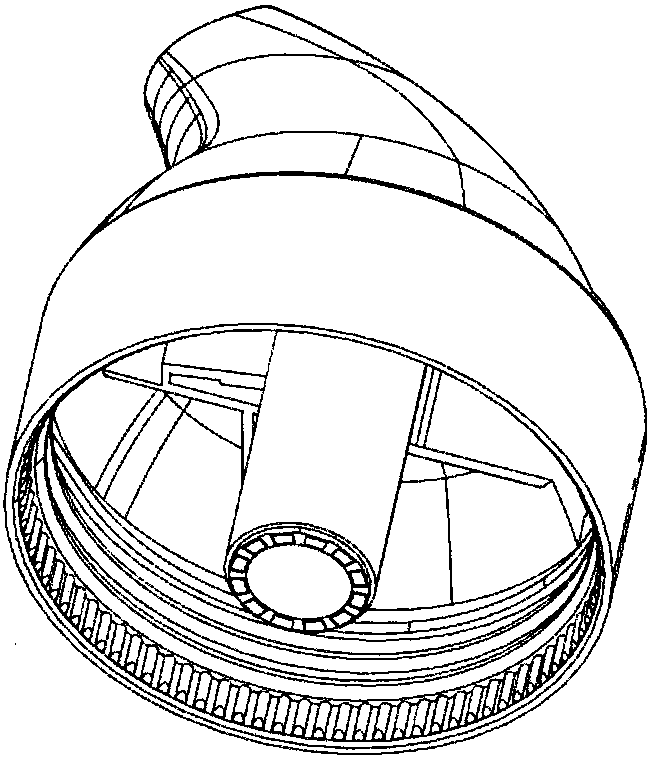

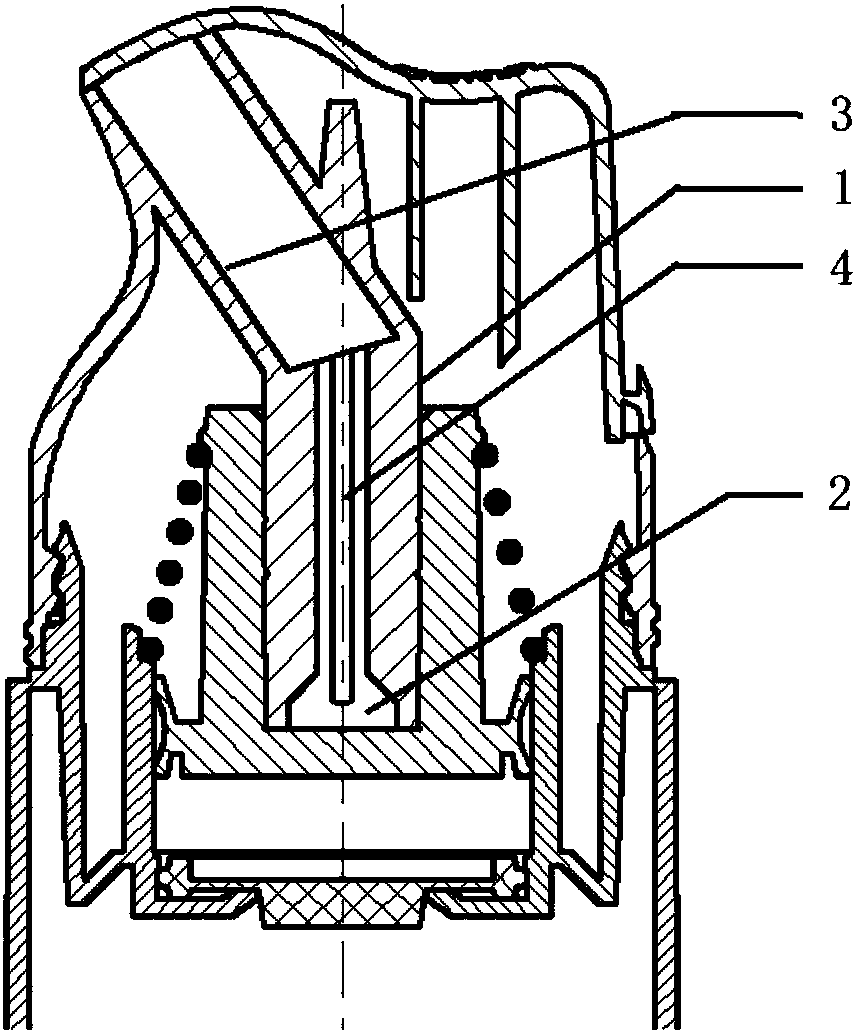

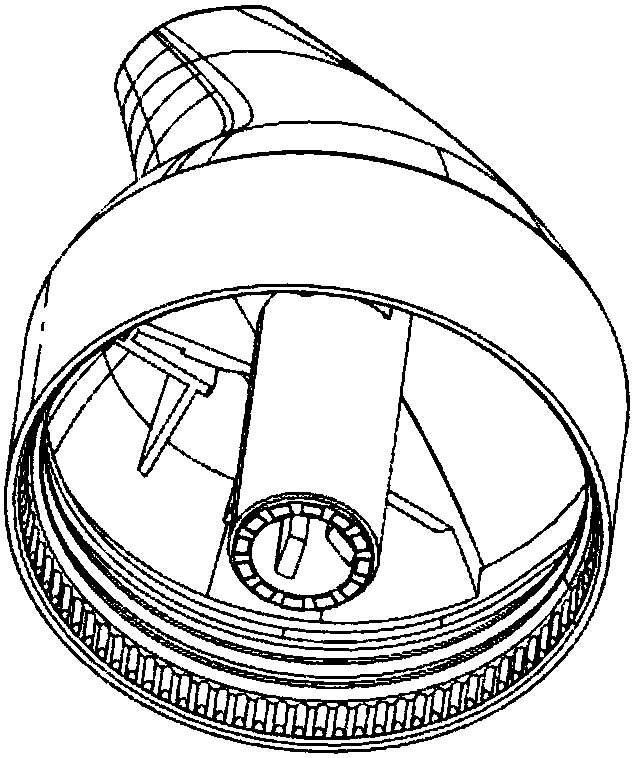

[0028] A self-priming pump pressure packaging bottle discharge pipe, such as figure 2 , 3 As shown in and 4, the outer edge of the cross-section of the discharge pipe 1 is circular, and the discharge pipe 1 is a folded pipe, which is composed of a straight pipe A 2 and a straight pipe B 3, and one end of the straight pipe A 2 is a discharge pipe feed end. The straight pipe A2 is provided with 4 convex strips 4 with the same length, the convex strips 4 are straight strips, parallel to the central axis of the straight pipe A2, the 4 convex strips 4 are evenly arranged in the discharge pipe 1 and the 4 convex strips The center of the strip 4 is located on the same horizontal plane, and the convex strip 4 and the discharge pipe 1 are integrally formed and processed.

[0029] It has been verified that when the discharge pipe of the self-priming pump-pressed packaging bottle of the present invention is used as a discharge pipe for thinner or lower-viscosity pastes, it can meet th...

Embodiment 2

[0031] A self-priming pump-pressed packaging bottle discharge pipe, the basic structure of which is the same as that of Embodiment 1, except that there are 6 convex strips in total, and the centers of the 6 convex strips are located on different horizontal planes, that is, the 6 convex strips are arranged alternately .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com