Construction method of gypsum sprayed wall

A construction method and wall spraying technology, applied in building structures, building components, walls, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of ensuring overall flatness, reliability, and reducing labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] Such as figure 2 Shown, the construction method of gypsum sprayed wall comprises the following steps:

[0039] Step S1, positioning and setting out: perform positioning and setting out according to the size requirements of the construction drawings;

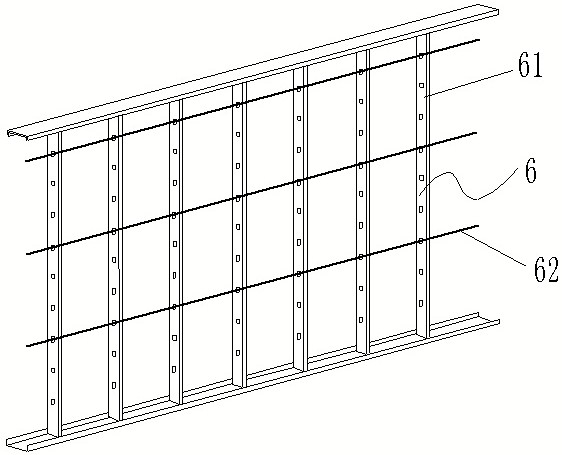

[0040] Step S2, keel installation: installing cold-formed thin-walled steel, that is, installing vertical keels 61 and penetrating keels 62 to form keel frames 6 in sequence according to the laying-out positions;

[0041] Step S3, install the formwork: install the fixed formwork on one side of the keel frame 6;

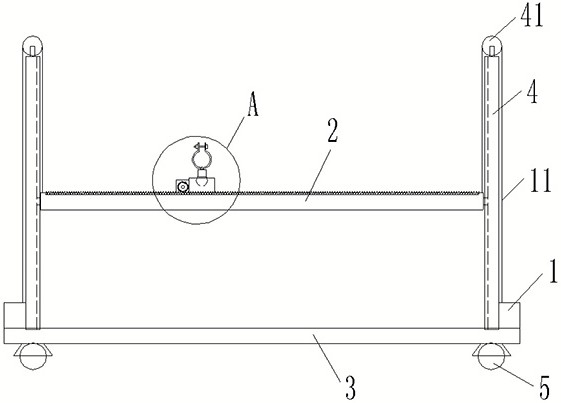

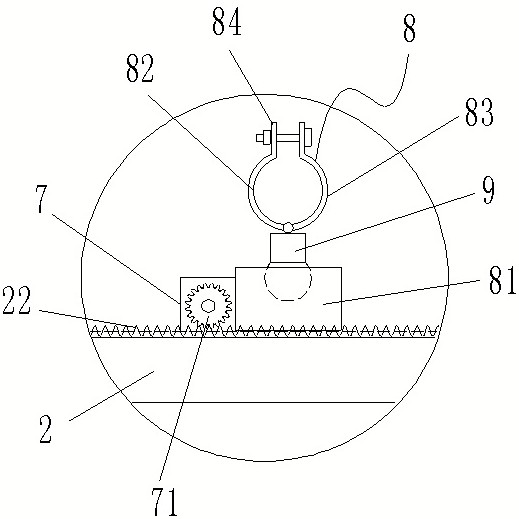

[0042] Step S4, spraying the wall: push the spraying auxiliary trolley to the area to be sprayed on the side of the keel frame 6 away from the fixed template, make the spraying auxiliary trolley lean against the keel frame 6 and fix it, so that the spraying pipe of the spraying machine is sprayed evenly towards the fixed template Composite gypsum slurry to a preset thickness, control the first driving device 1 ...

specific Embodiment 2

[0053] The construction method of gypsum sprayed wall comprises the following steps:

[0054] Step S1, positioning and setting out: perform positioning and setting out according to the size requirements of the construction drawings;

[0055] Step S2, keel installation: installing cold-formed thin-walled steel, that is, installing vertical keels 61 and penetrating keels 62 to form keel frames 6 in sequence according to the laying-out positions;

[0056] Step S3, install the formwork: install the fixed formwork on one side of the keel frame 6;

[0057] Step S4, spraying the wall: push the spraying auxiliary trolley to the area to be sprayed on the side of the keel frame 6 away from the fixed template, make the spraying auxiliary trolley lean against the keel frame 6 and fix it, so that the spraying pipe of the spraying machine is sprayed evenly towards the fixed template Composite gypsum slurry to a preset thickness, control the first driving device 1 to drive the smoothing sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com