Pipeline defect identification method of suppression-end intrinsic time scale decomposition

A technology of inherent time scale and defect identification, applied in the field of information detection, which can solve problems such as end-effects easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

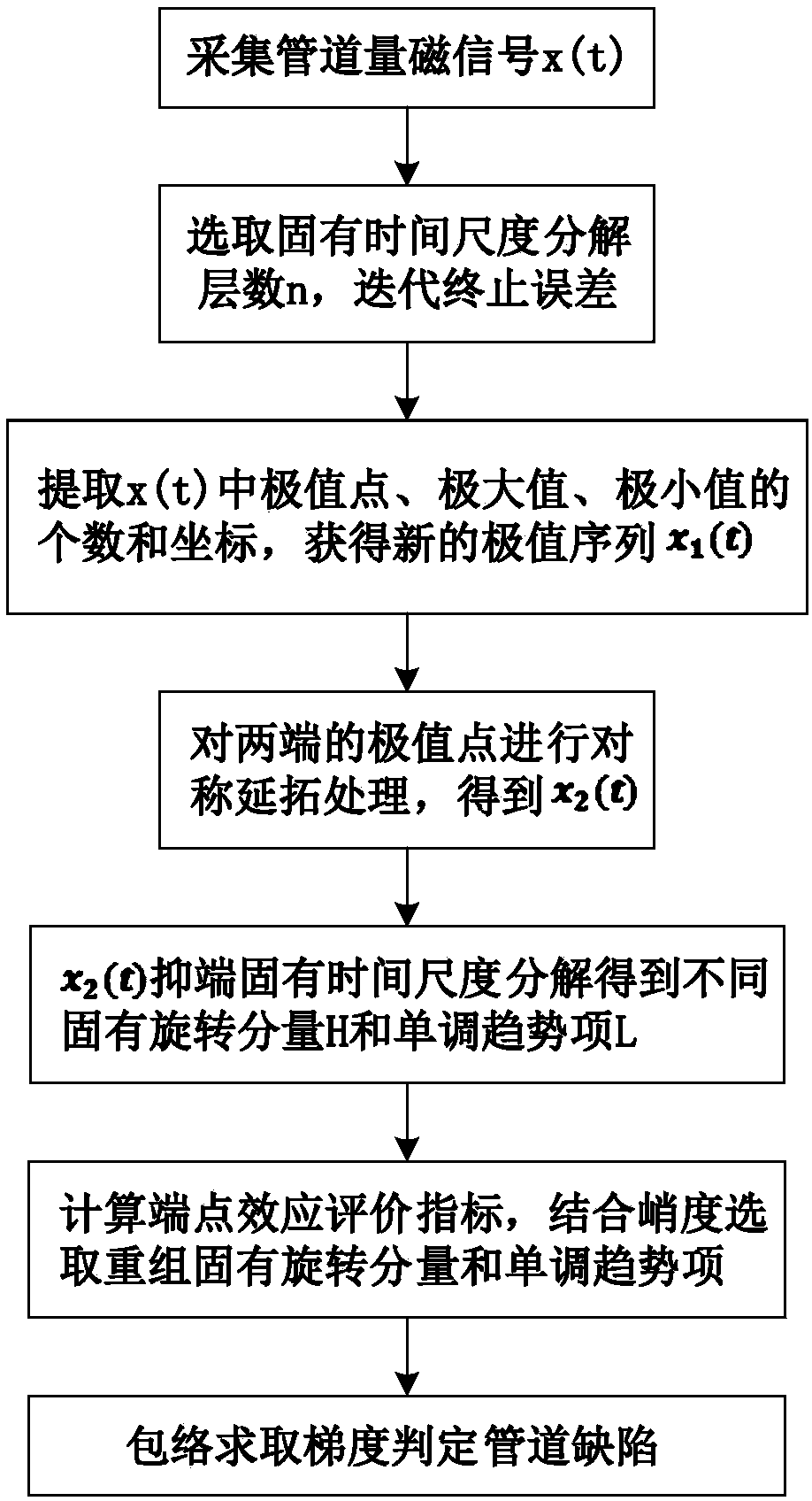

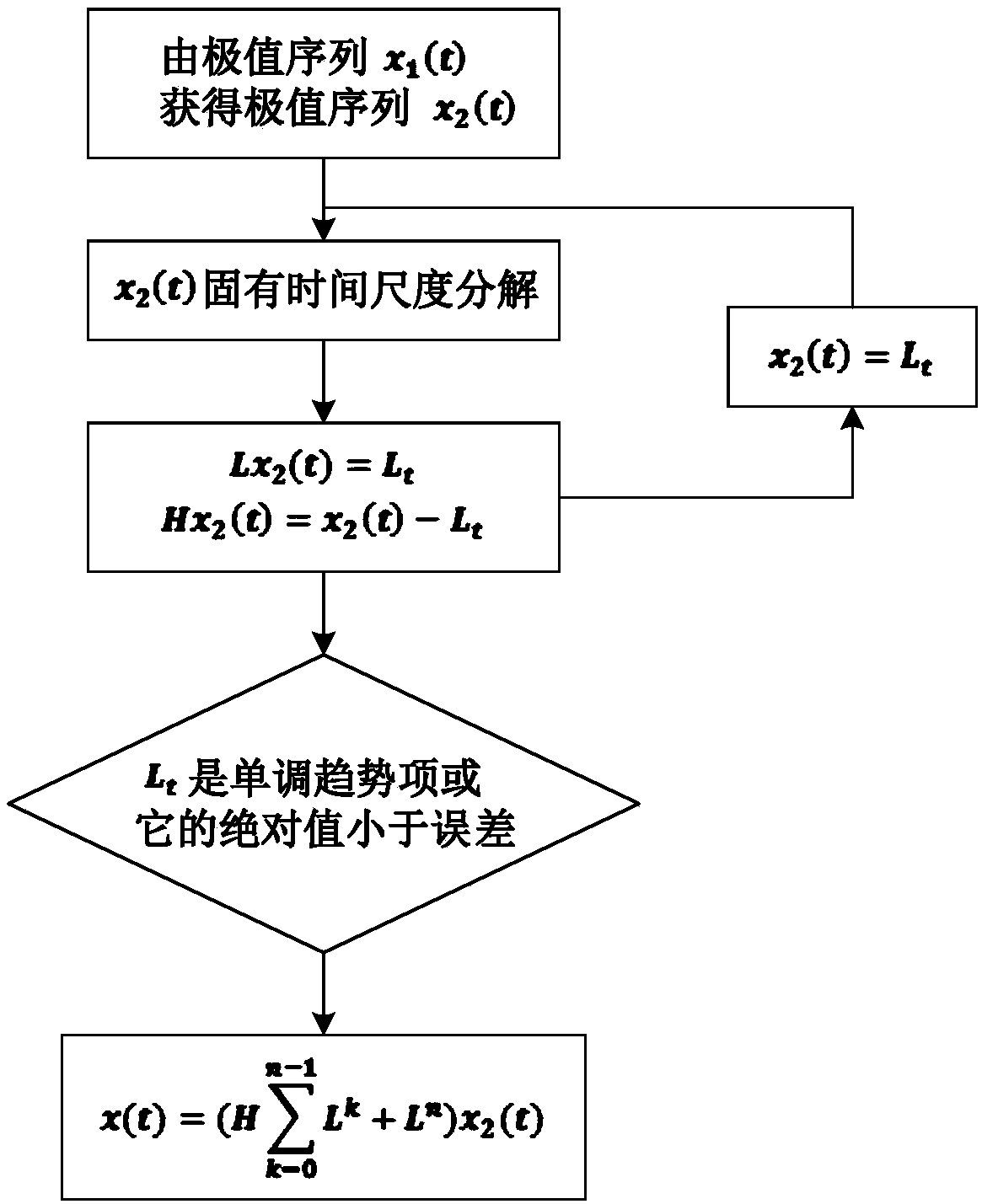

[0070] The pipeline defect identification method based on the inherent time scale decomposition of the suppression end of the present invention, such as figure 1 As shown, its main steps include:

[0071] Step 1: Use the fluxgate probe to collect the magnetic signal x(t) of the pipeline. According to the actual signal x((t), select the number of decomposition layers of the inherent time scale decomposition of the suppression end, and iterate to terminate the error.

[0072] Step 2: Extract the number of extreme points, coordinates of extreme points, coordinates of maximum values and coordinates of minimum values in the signal x(t), and obtain a new sequence of extreme values x 1 (t);

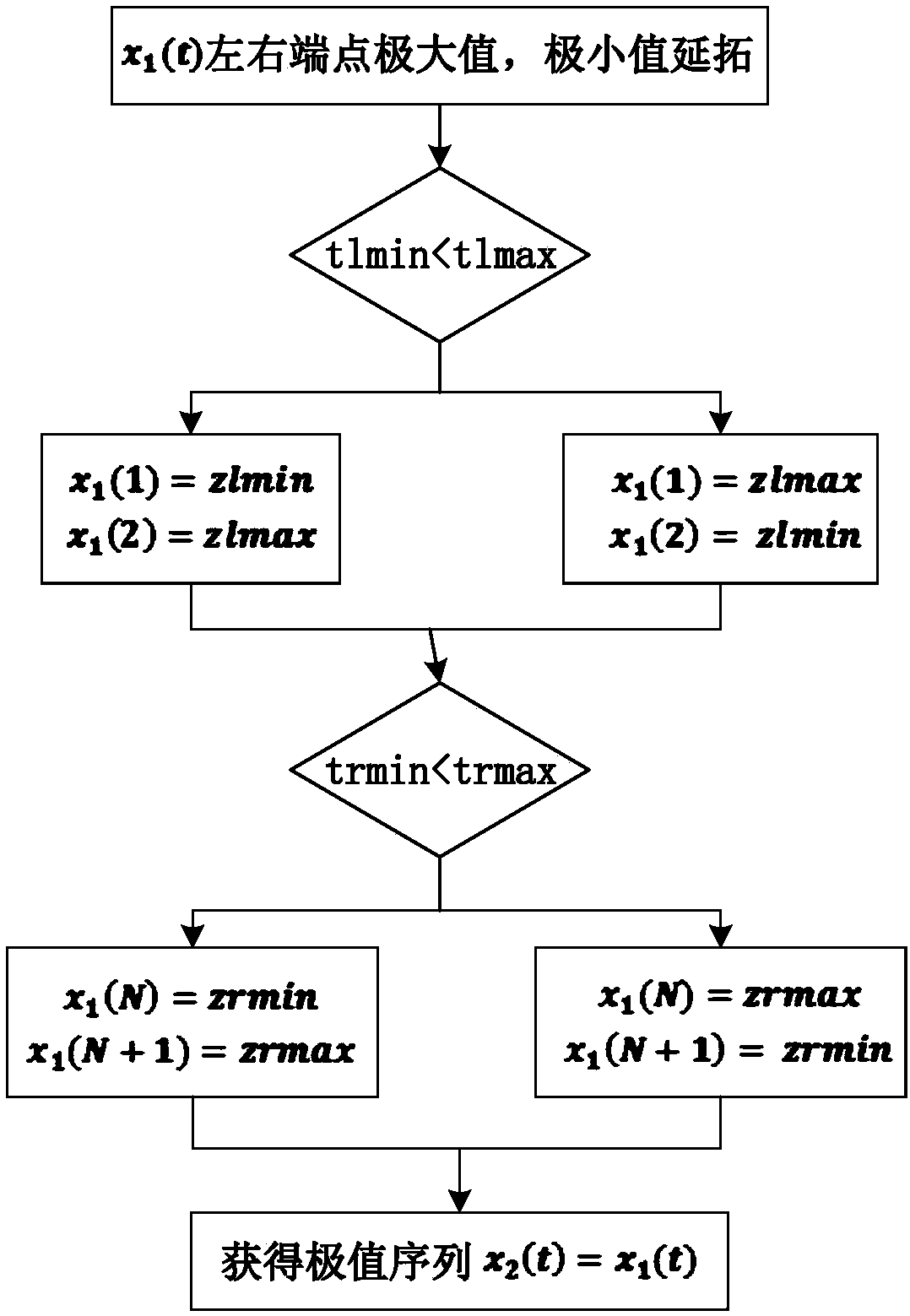

[0073] Step 3: For the extremum sequence x 1 The endpoints of (t) are subjected to symmetrical extension processing to obtain the upper and lower envelopes of the extreme values of the signal, such as figure 2 as shown,

[0074] The process of left endpoint processing is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com