Display device, manufacturing method thereof, and manufacturing device

A display device and display surface technology, which is applied to instruments, nonlinear optics, optics, etc., can solve problems such as insufficient correction of bright spot defects, light leakage, and thinning of the scanning section, and achieve the effect of suppressing bright spot defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

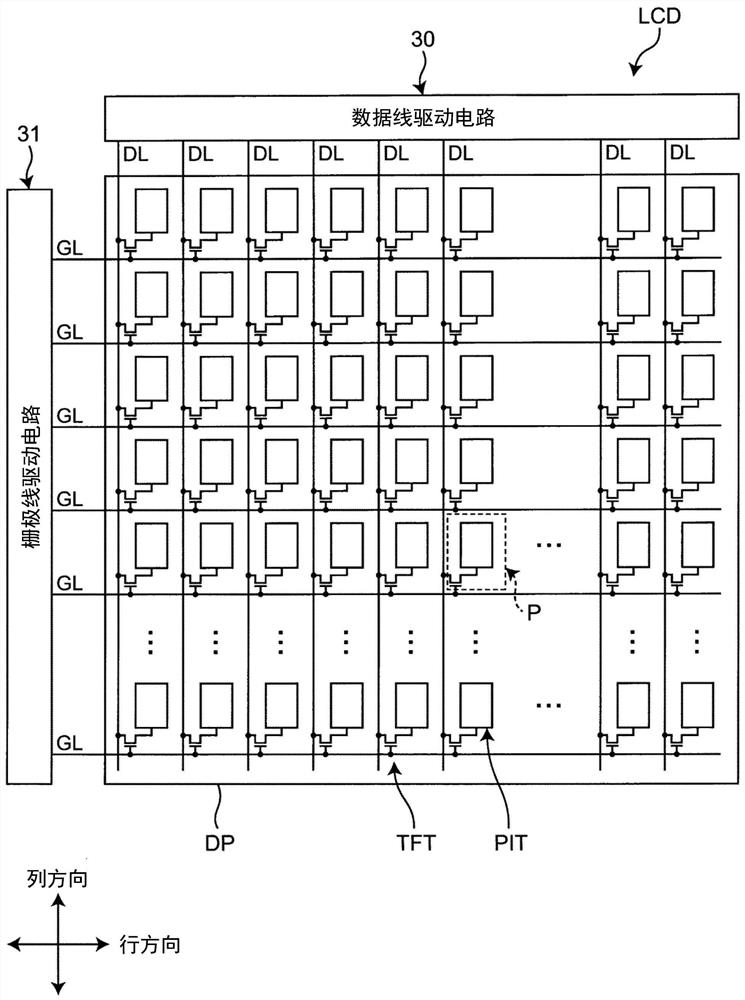

[0099] figure 1 It is a plan view showing the overall configuration of a liquid crystal display device LCD as an example of the display device according to Embodiment 1 of the present invention.

[0100] The liquid crystal display device LCD includes: a display panel DP for displaying images, a display panel drive circuit (data line drive circuit 30, gate line drive circuit 31) for driving the display panel DP, and a control circuit (not shown) for controlling the display panel drive circuit. ) and a backlight 134 that illuminates the backlight that irradiates light to the display panel DP from the rear side.

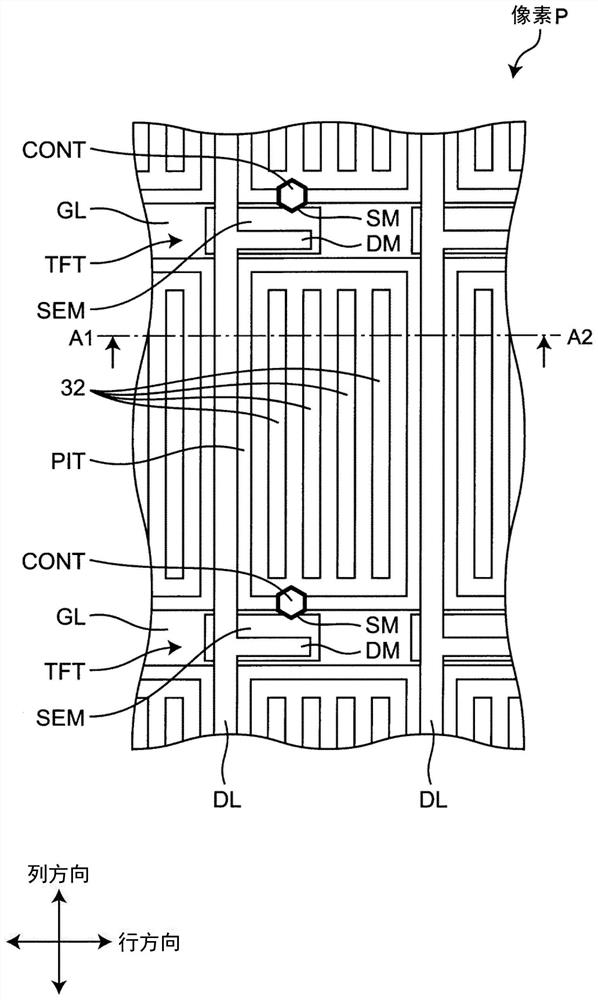

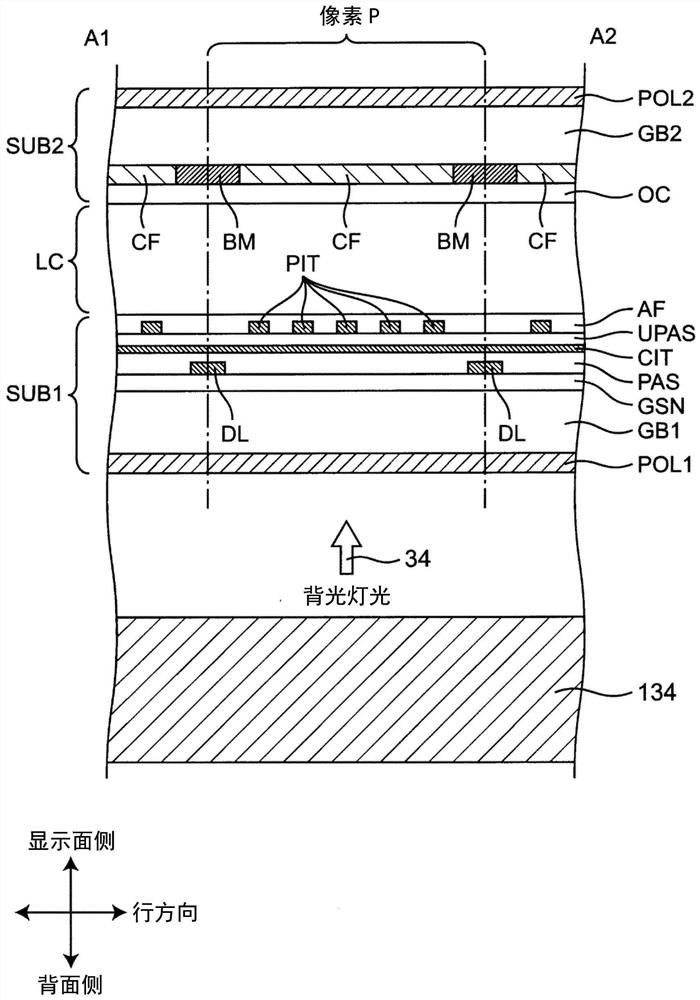

[0101] figure 2 It is a plan view showing the configuration of a part of the display panel DP. image 3 is in figure 2 The end view of the cut part cut at the line A1-A2 of . In addition, in figure 2 as well as image 3 , represents a pixel P in the display panel DP.

[0102] like image 3 As shown, the display panel DP includes: a thin film transistor substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com