Quick packaging meal box capable of achieving free space distribution

A lunch box, fast technology, applied in the direction of packaging, sealing, internal accessories, etc., can solve the problems of poor sealing effect, easy to expand and deform due to heat, easy deformation of sealing rubber ring, etc., to achieve improved sealing, convenient use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

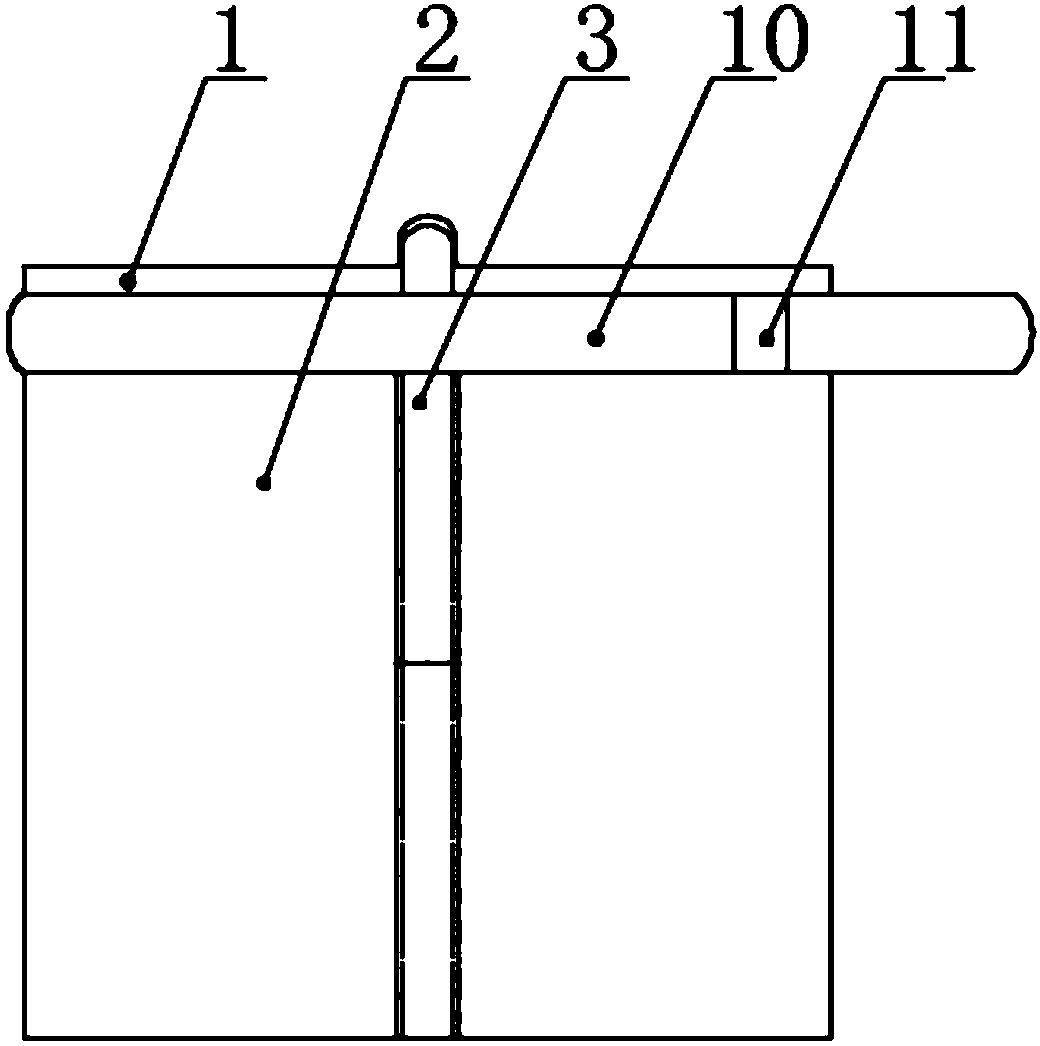

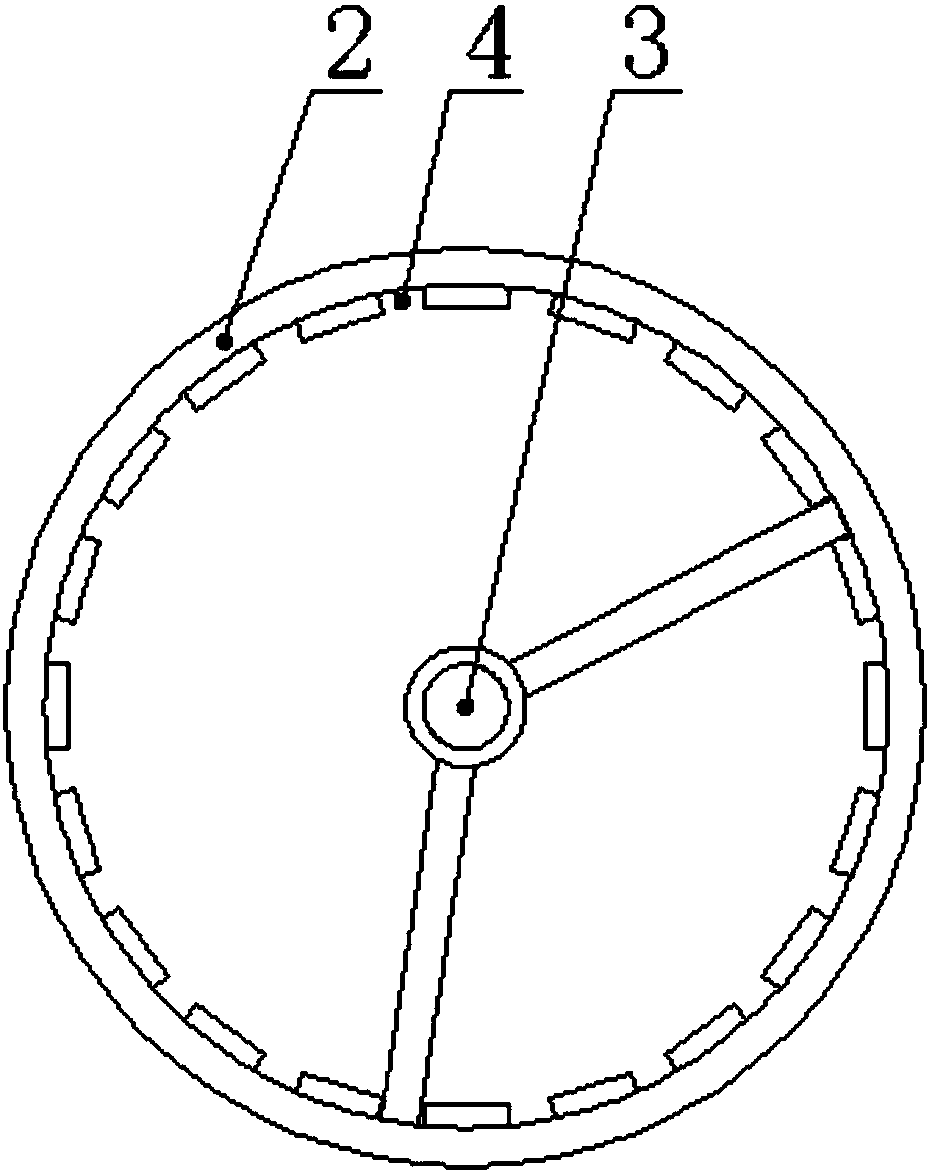

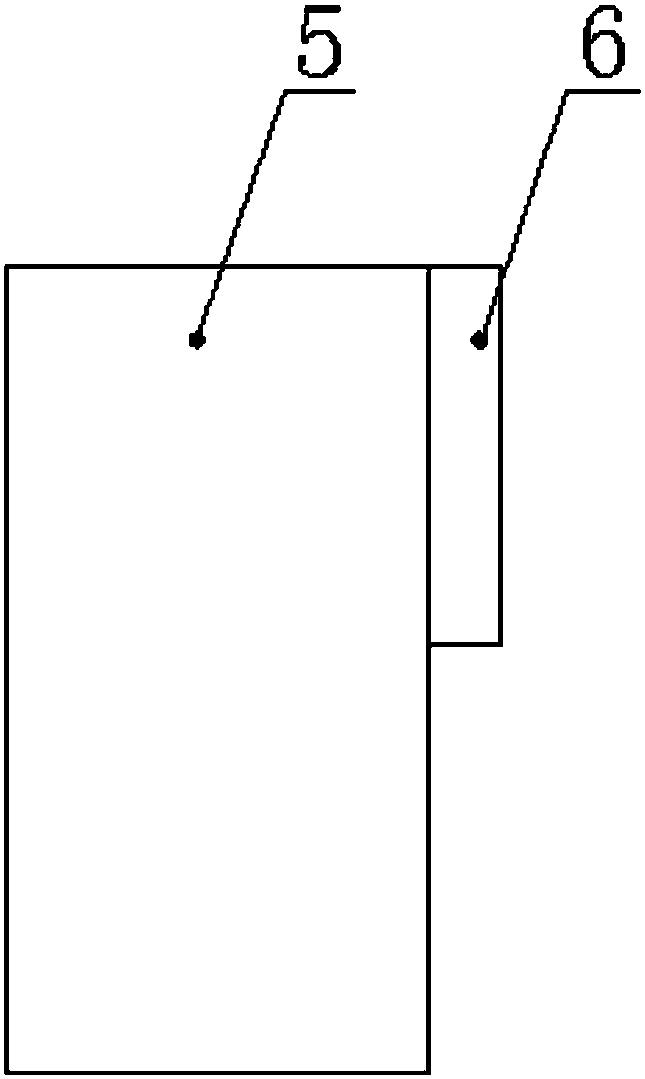

[0026] A fast-package lunch box that can freely distribute space, including two lunch box bodies, one lunch box cover and a quick-pack easy-to-pull ring, the lunch box cover is embedded on the lunch box body, and the lunch box body is a cylindrical structure. The center of the bottom circle of the lunch box body is integrally formed with 3 fixing columns that run through the lunch box body longitudinally, and a plurality of 4 fixing grooves are evenly distributed on the inner wall of the lunch box; 5 upper baffles and 7 lower baffles, and the ends of the upper and lower baffles are just fixed on the fixing groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com