Fully automatic intelligent logistics system and method for carton production

A logistics system, fully automatic technology, applied in the field of intelligent logistics, can solve the problems of high labor intensity, affecting production, restricting the production efficiency of production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

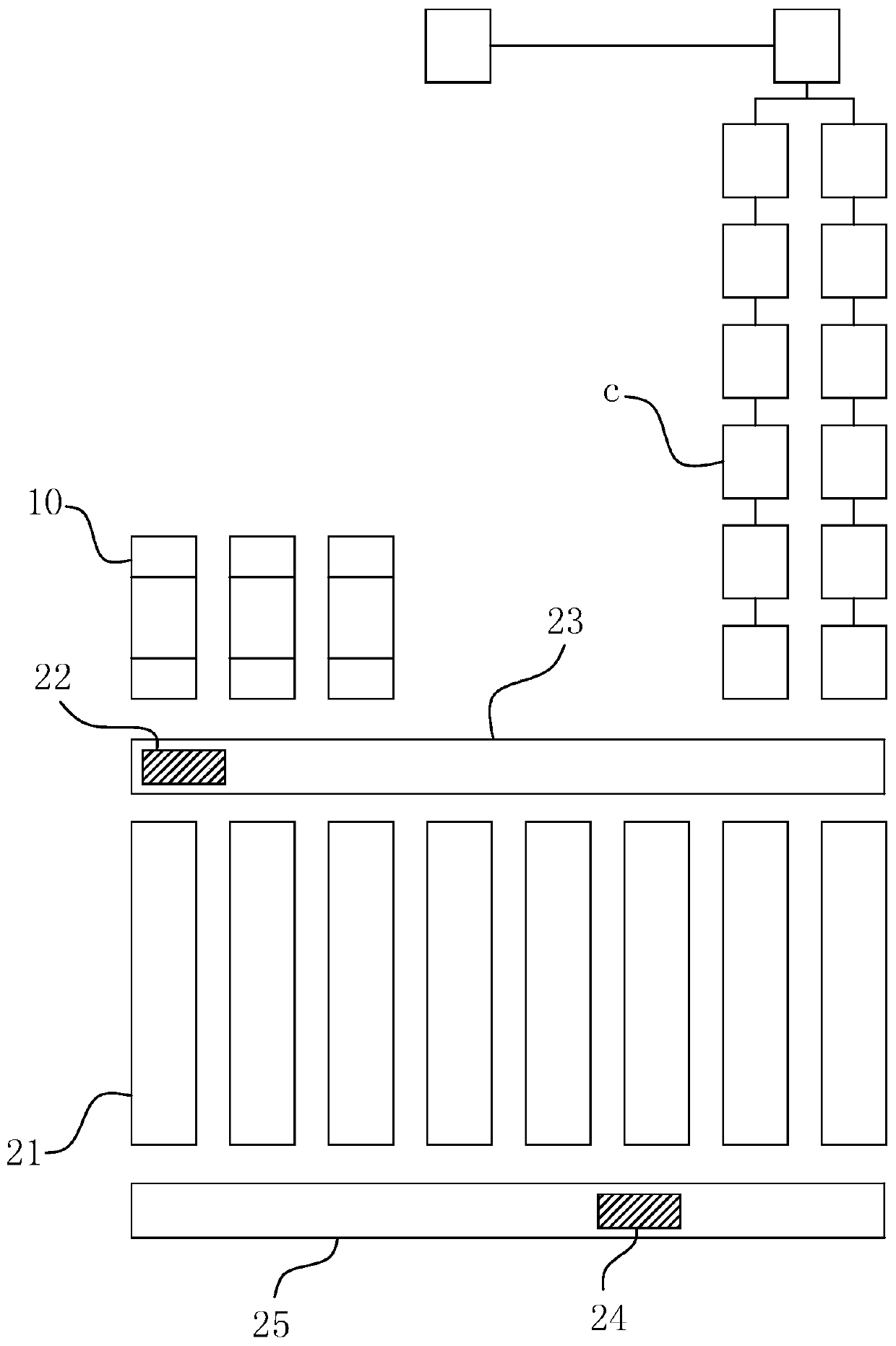

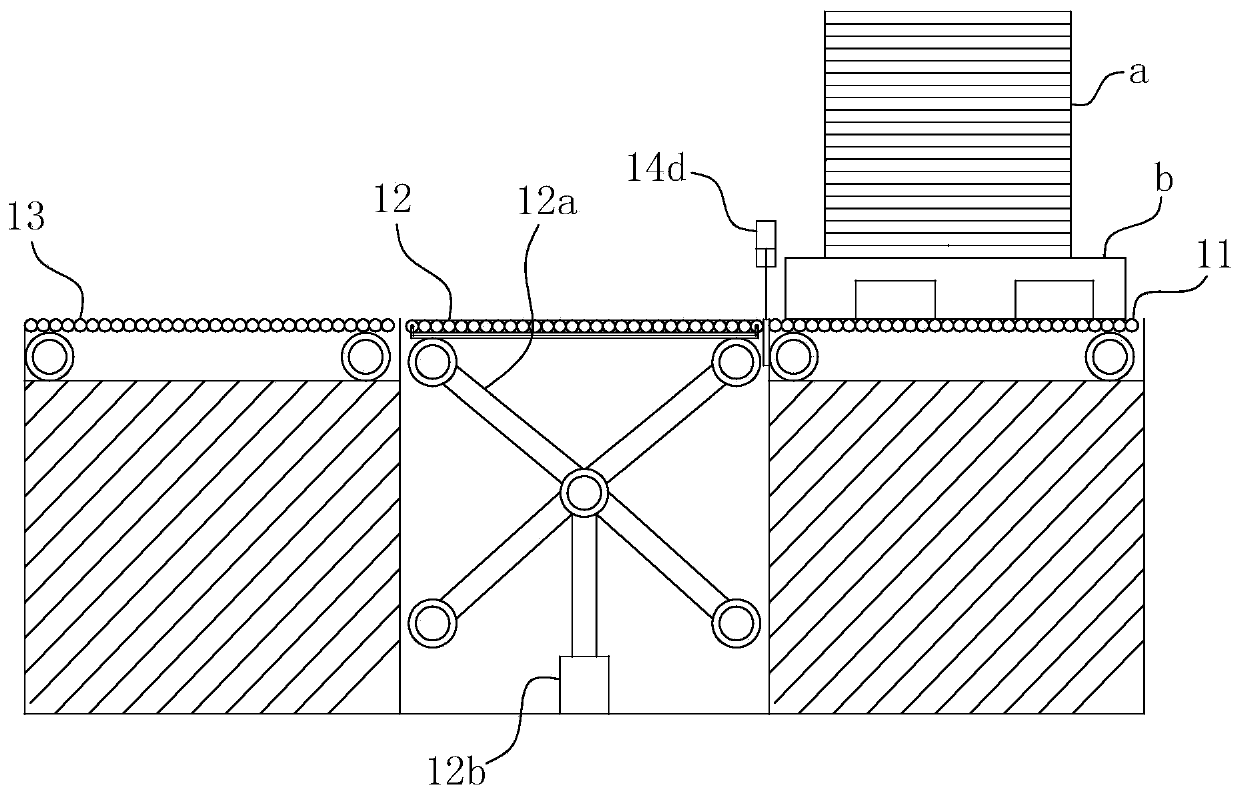

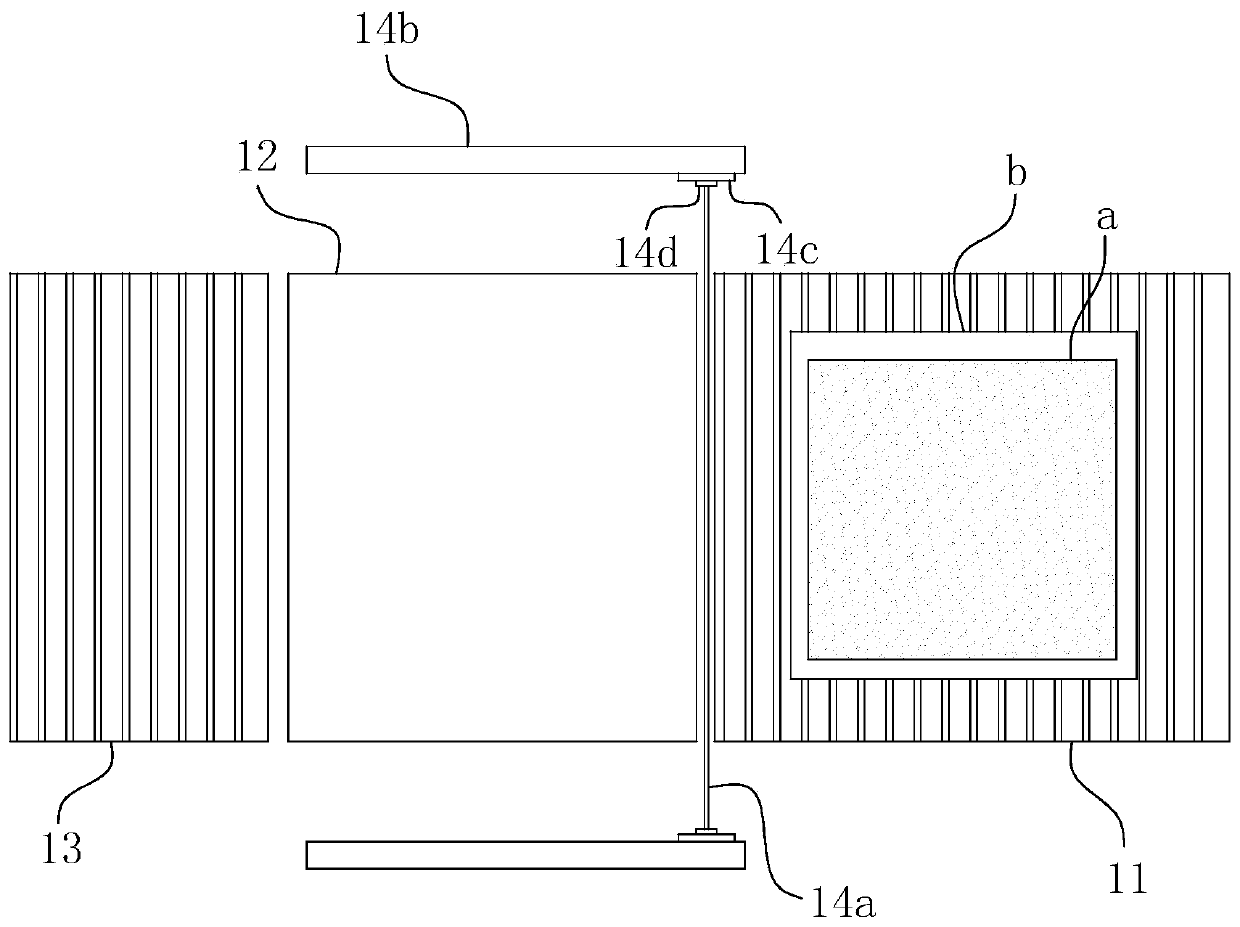

[0062] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

[0063] ERP system is the abbreviation of Enterprise Resource Planning (Enterprise Resource Planning). management platform. ERP system is integrated, advanced, unified, complete and open. The ERP system is applied to the logistics system provided by the present invention, so that machines and equipment from different countries, different brands, and different processes can be connected in series to form an automatic production line, thereby reducing on-site manpower and reducing loss during process handover. And simultaneously reduce the time-consuming connection between different processes, etc., to achieve a great saving of resources. The logistics system of the present invention is mainly used as the front-end paper loading process of a corrugated box factory, and its purpose is mainly to autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com