A shock-absorbing bridge structure

A technology of bridge structure and shock-absorbing support, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of improving the shock-absorbing support, reducing the transmission acceleration, and the inability of the shock-absorbing support to reach an appropriate height, so as to improve the stability , Improve the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

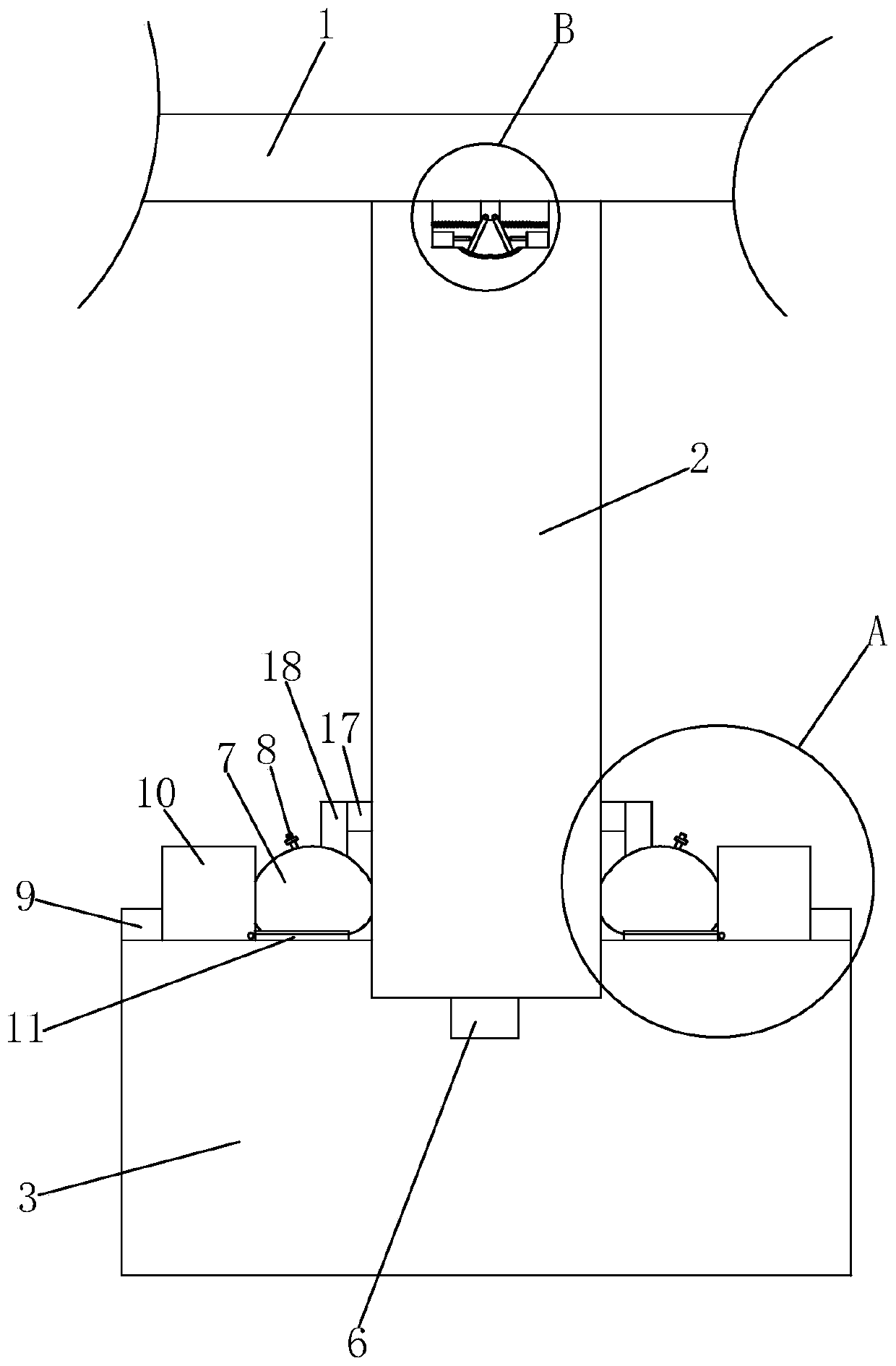

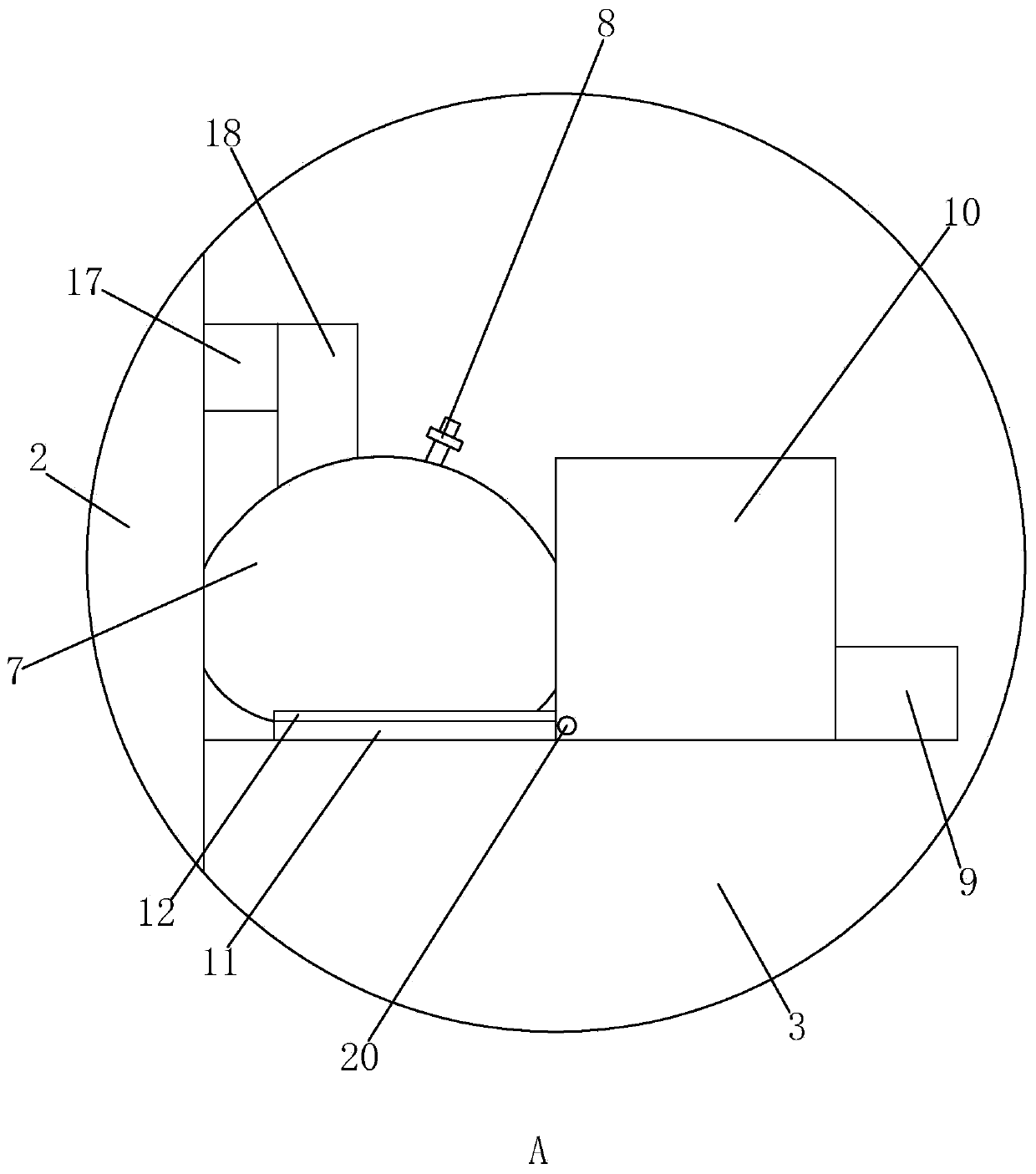

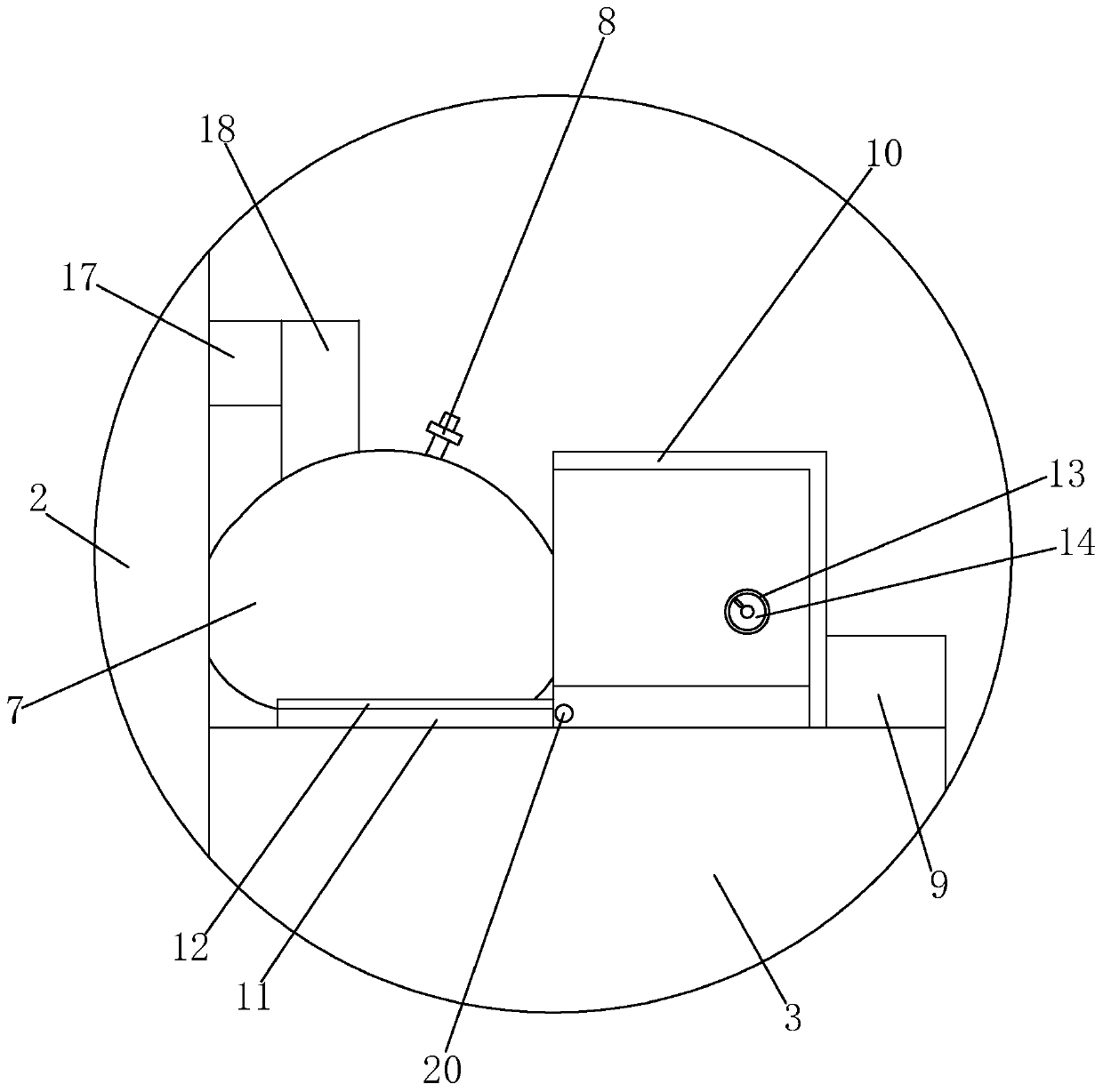

[0036] A kind of shock-absorbing bridge structure, refer to figure 1 As shown, it includes bridge deck 1, bridge column 2 and bridge pier 3.

[0037] Among them, refer to figure 1 and Figure 4 As shown, between the bridge deck 1 and the bridge column 2, there is a shock absorber 4 for reducing the force in the vertical direction. The shock absorber 4 belongs to the rubber bearing, and the shock absorber 4 includes a Mounting block 41 , the bottom end of mounting block 41 is rotated by first hinge shaft 19 to be provided with two rotating brackets 42 , and the two rotating brackets 42 are arranged symmetrically.

[0038] The top of the bridge column 2 is provided with an abutting groove 21 for the rotation of the rotating bracket 42 below the mounting block 41. The abutting groove 21 is a part drawn as a circle with the first hinge shaft 19 as the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com