Bicycle rack measuring method

A bicycle frame and measurement technology, which is applied to measurement devices, instruments, optical devices, etc., to achieve the effect of improving reliability and accuracy, and fast and convenient measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical content and characteristics of the present invention will be described in detail below by referring to several preferred embodiments in conjunction with the accompanying drawings. Directions such as "front", "rear", "upper" and "lower" mentioned in the content of this specification The adjectives are only illustrative descriptions based on the normal use direction of the bicycle rack 10, and are not intended to limit the scope of claims

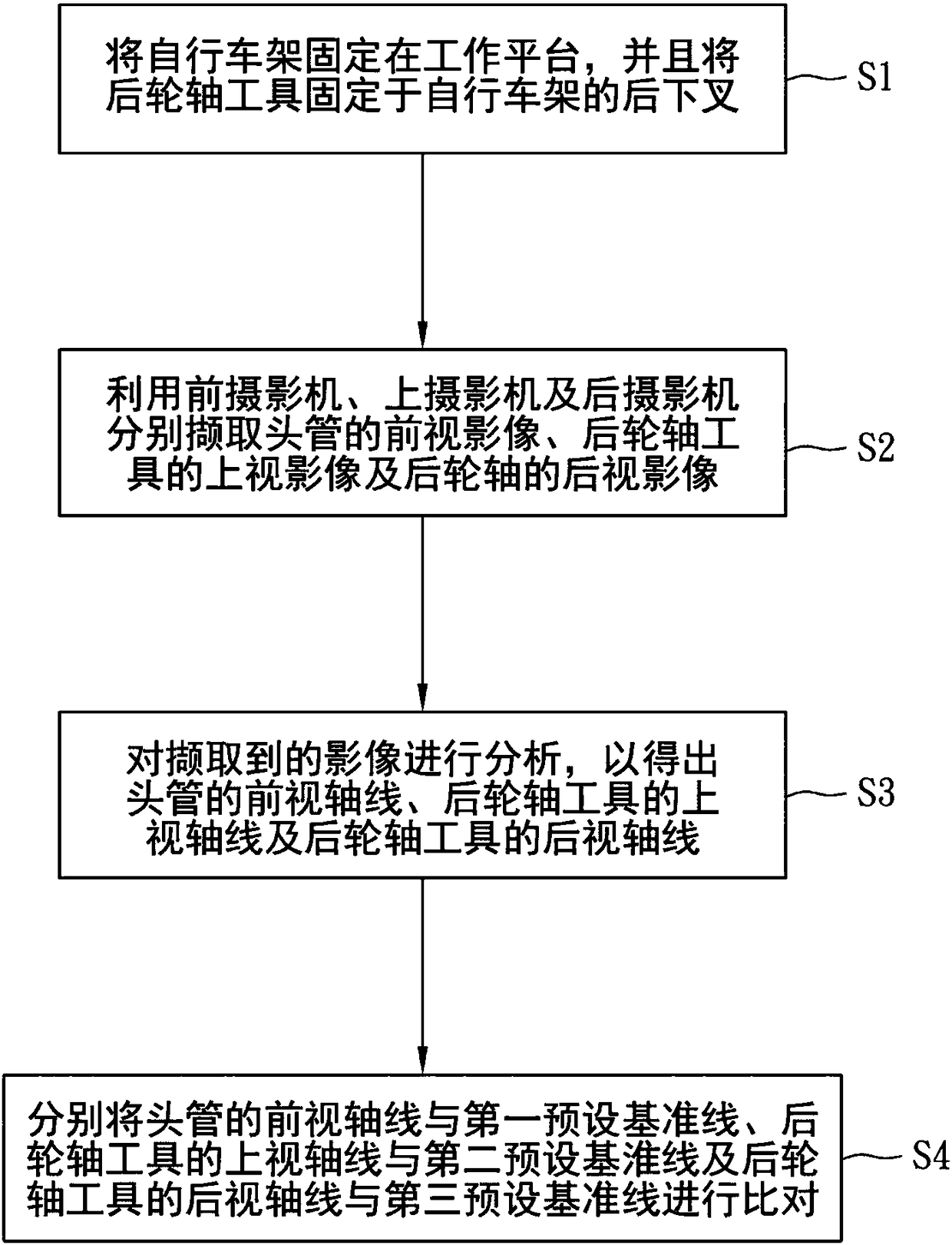

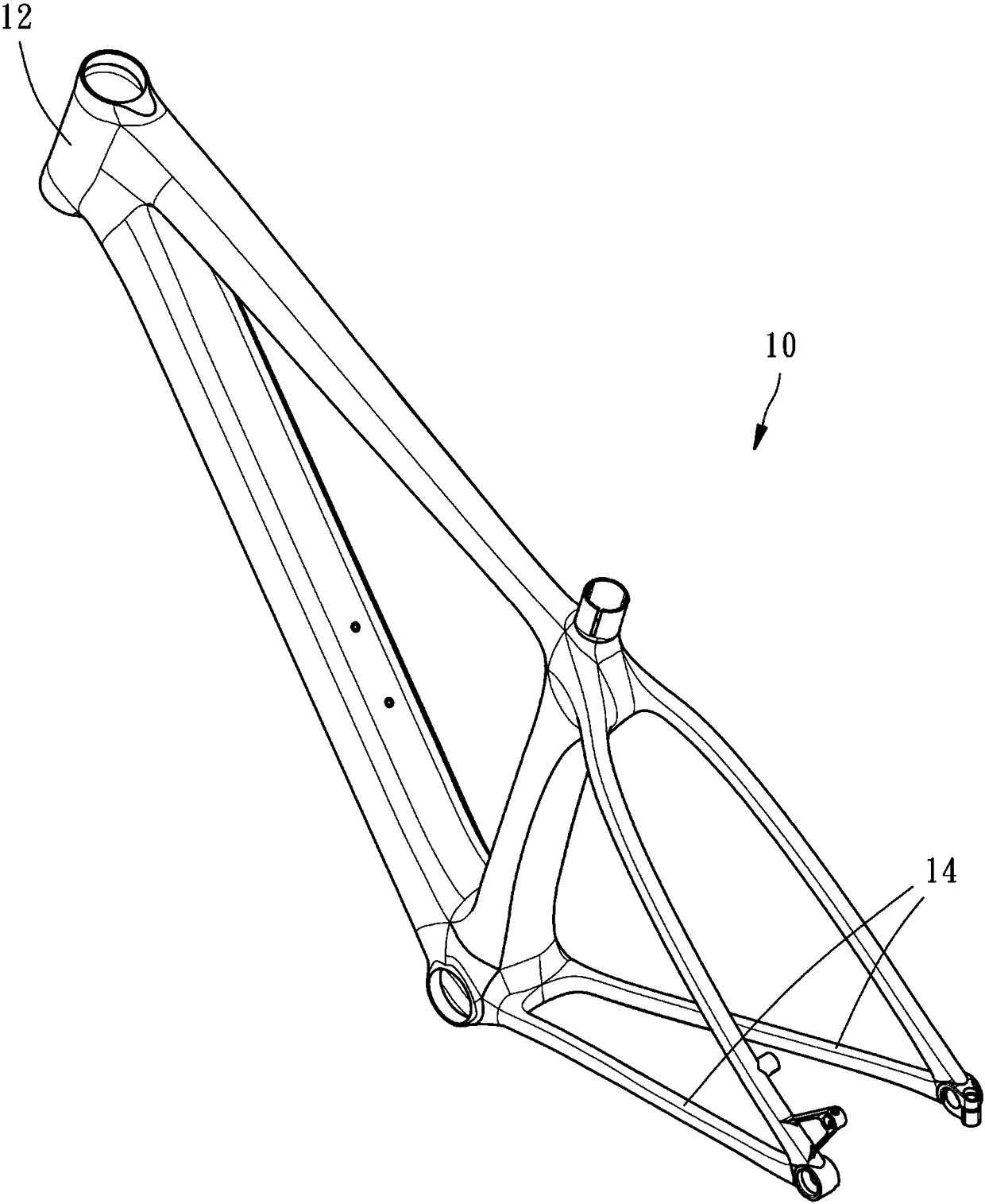

[0029] Please see first figure 2 , the bicycle frame 10 shown in the figure comprises a head tube 12 and a pair of chainstays 14, please refer to figure 1 , the present invention comprises the following steps for the measurement method of bicycle frame 10:

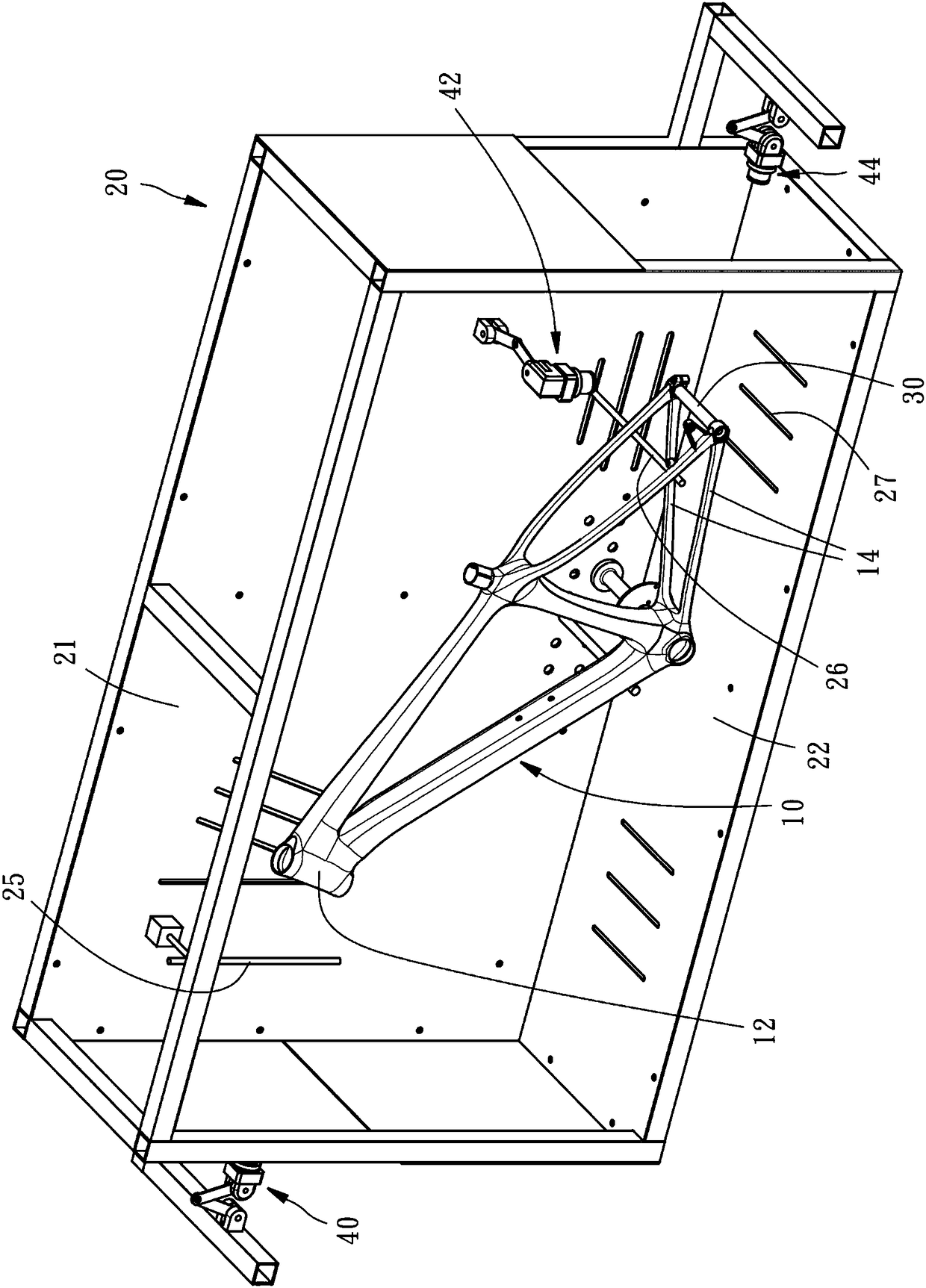

[0030] a) if image 3 As shown, the bicycle frame 10 is fixed on a working platform 20 , and a rear axle tool 30 is fixed on the chainstay 14 of the bicycle frame 10 . In addition, the working platform 20 is provided with a front camera 40, an upper camera 42 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com