Large-diameter strip ring gauge and method for calibrating same

A calibration method and a large-diameter technology are applied to ring gauges, measuring gauges, etc., to achieve the effect of overcoming measurement problems and being easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

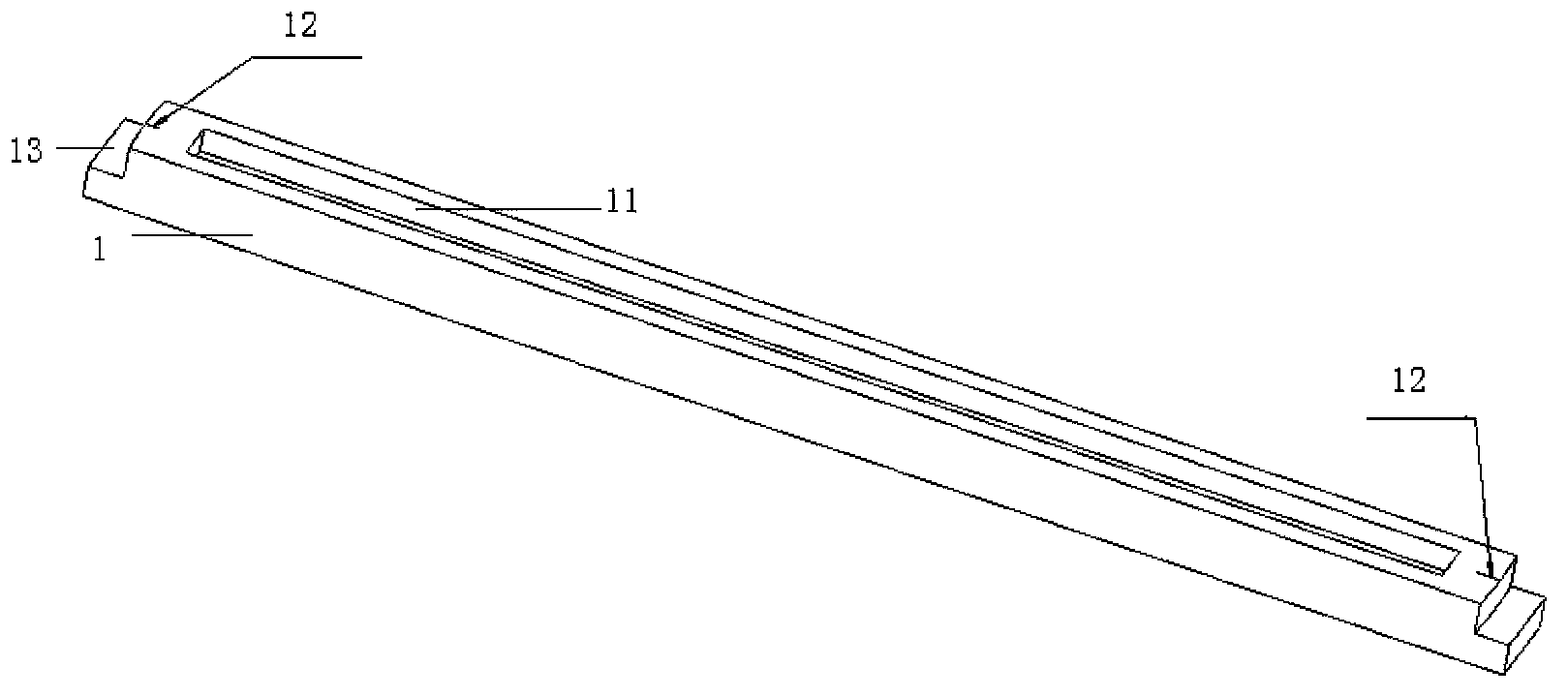

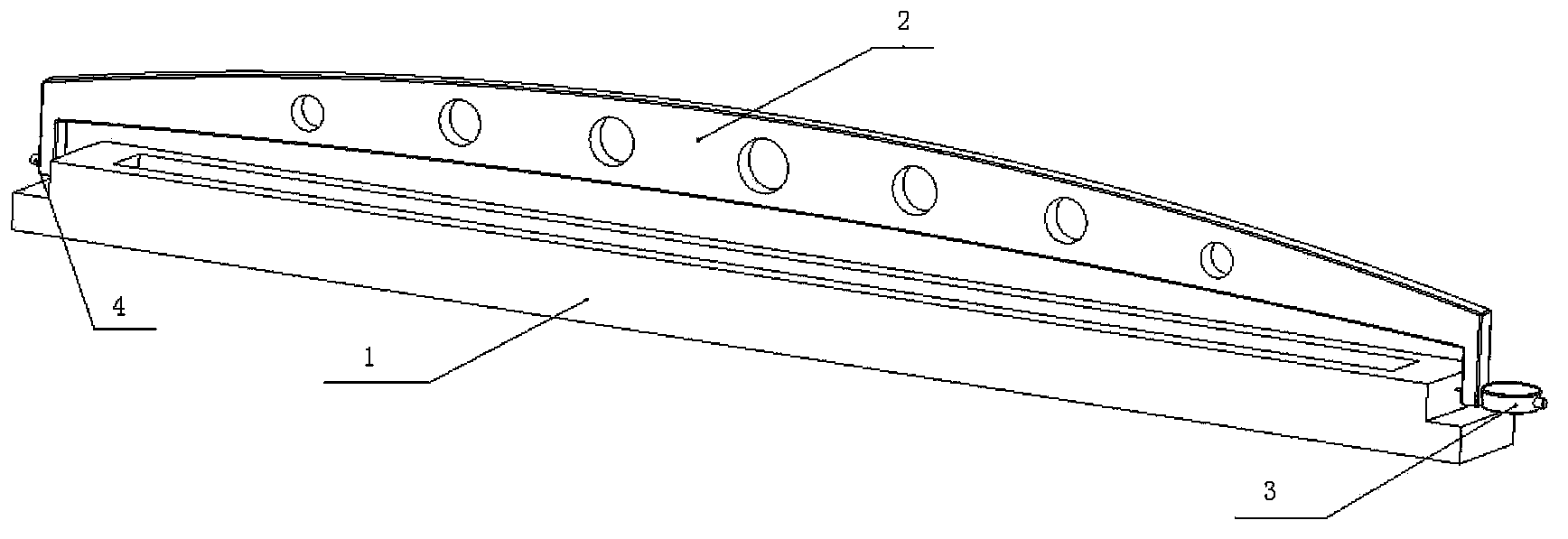

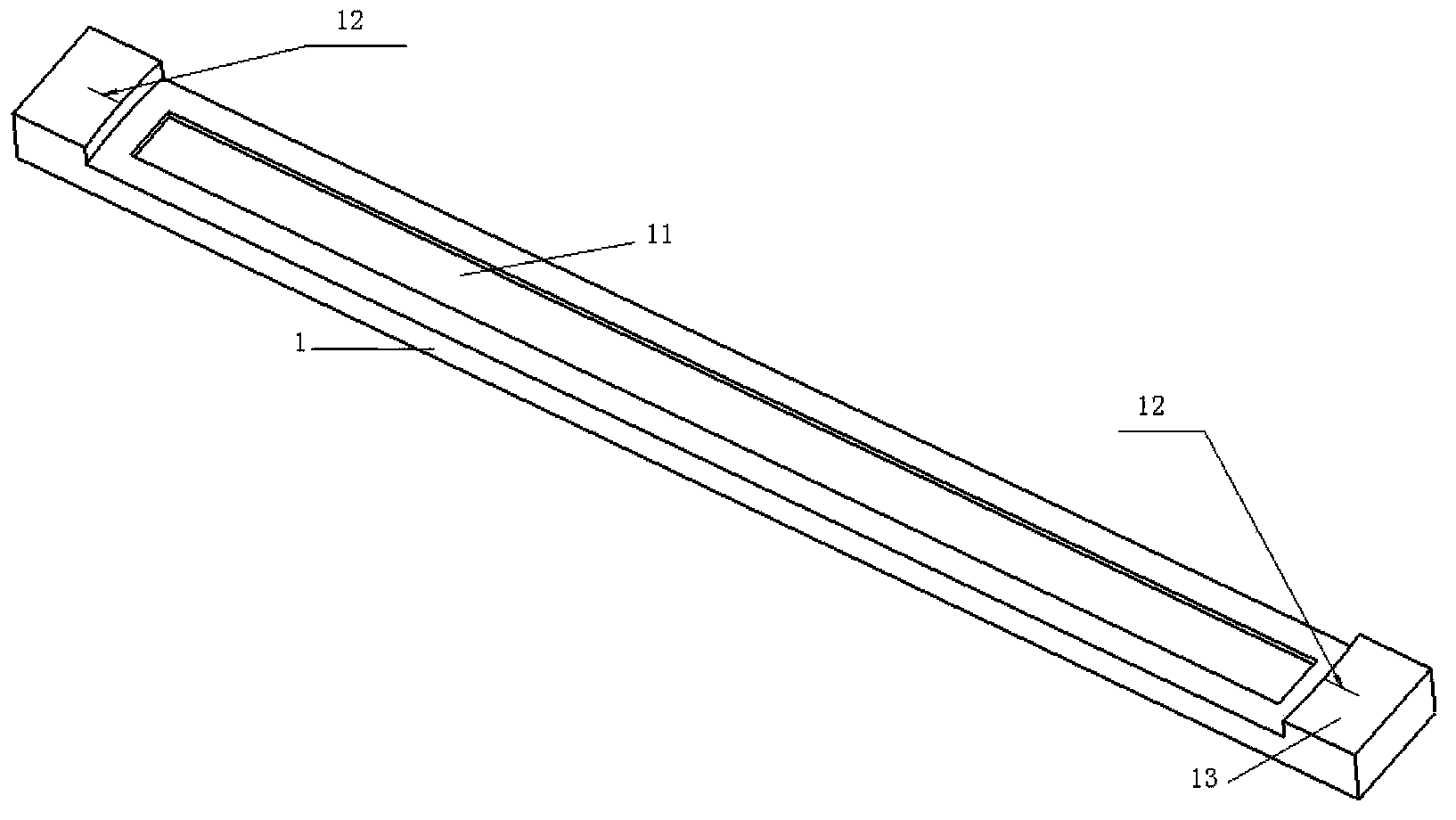

[0026] refer to Figure 1 to Figure 4 , the calibration method of the large-diameter bar ring gauge, the steps of the calibration method are as follows:

[0027] (1) First place the bar ring gauge on the plate for temperature balance;

[0028] (2) Then place the ring gauge on the three equal height blocks on the workbench of the coordinate machine, and clean the reference plane and the measuring surface of the ring gauge with an alcohol cotton ball;

[0029] (3) Start the coordinate machine, find out the working plane according to the operation program of the coordinate machine, establish a coordinate system, and collect points at equal intervals on the arcs at both ends, and the number of points collected on each arc is not less than 5 points. The distance between the points is not less than 4mm; the position of the center of the arc is measured by the least square method, and a straight line is set on the arc surface through the center point, and the intersection point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com