Organic light-emitting display panel, preparation method therefor, and organic light-emitting display device

A technology for light-emitting display and organic light-emitting devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as changes and color shift of OLED display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

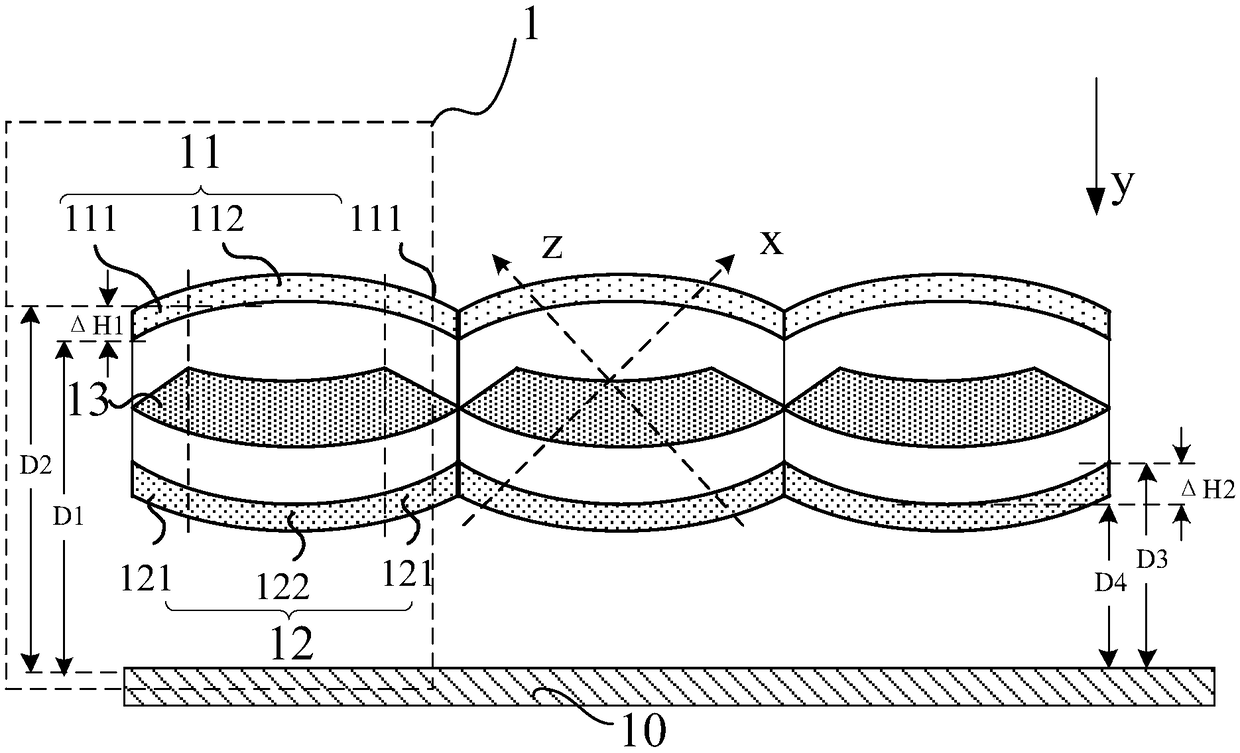

[0054] This embodiment also provides a method for preparing an organic light-emitting display panel, such as figure 1 and Figure 9 as shown, Figure 9 It is a schematic flow chart of the method for preparing an organic light-emitting display panel provided in this embodiment; the preparation method includes:

[0055] S1: providing a base substrate 10;

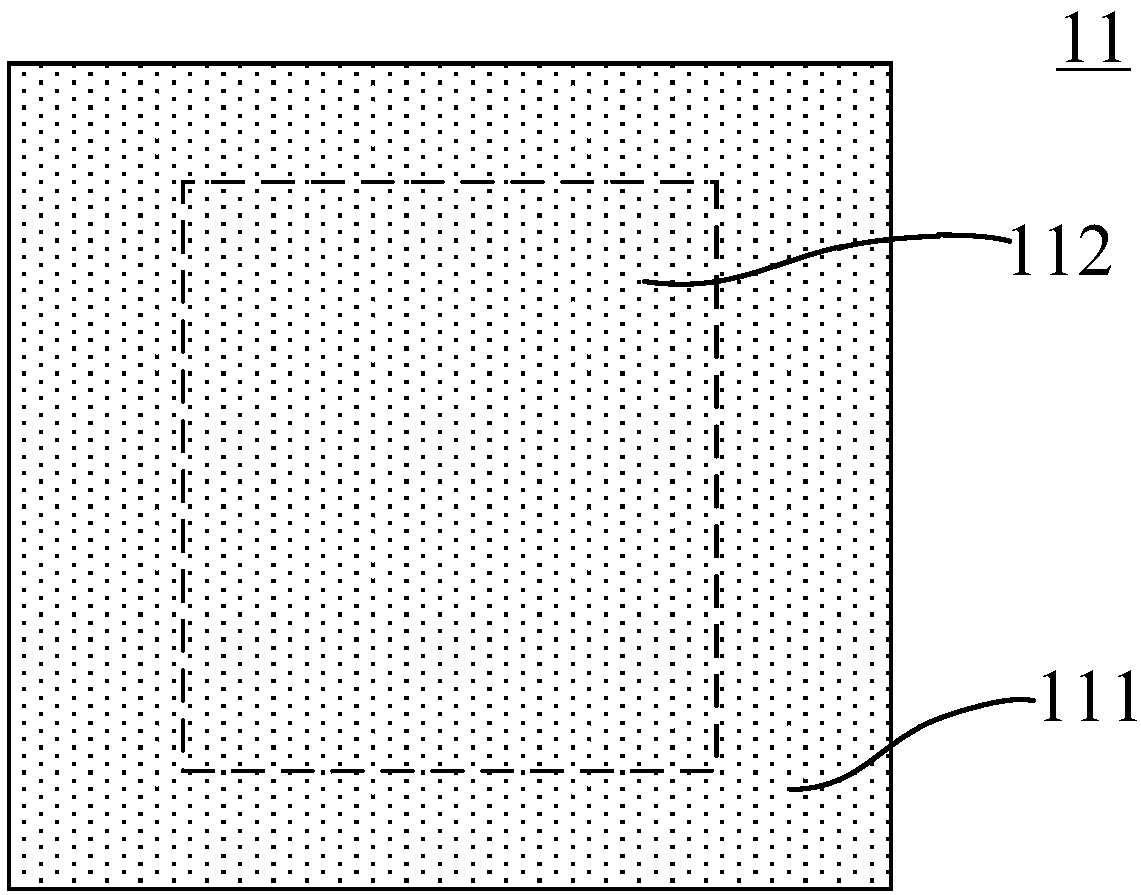

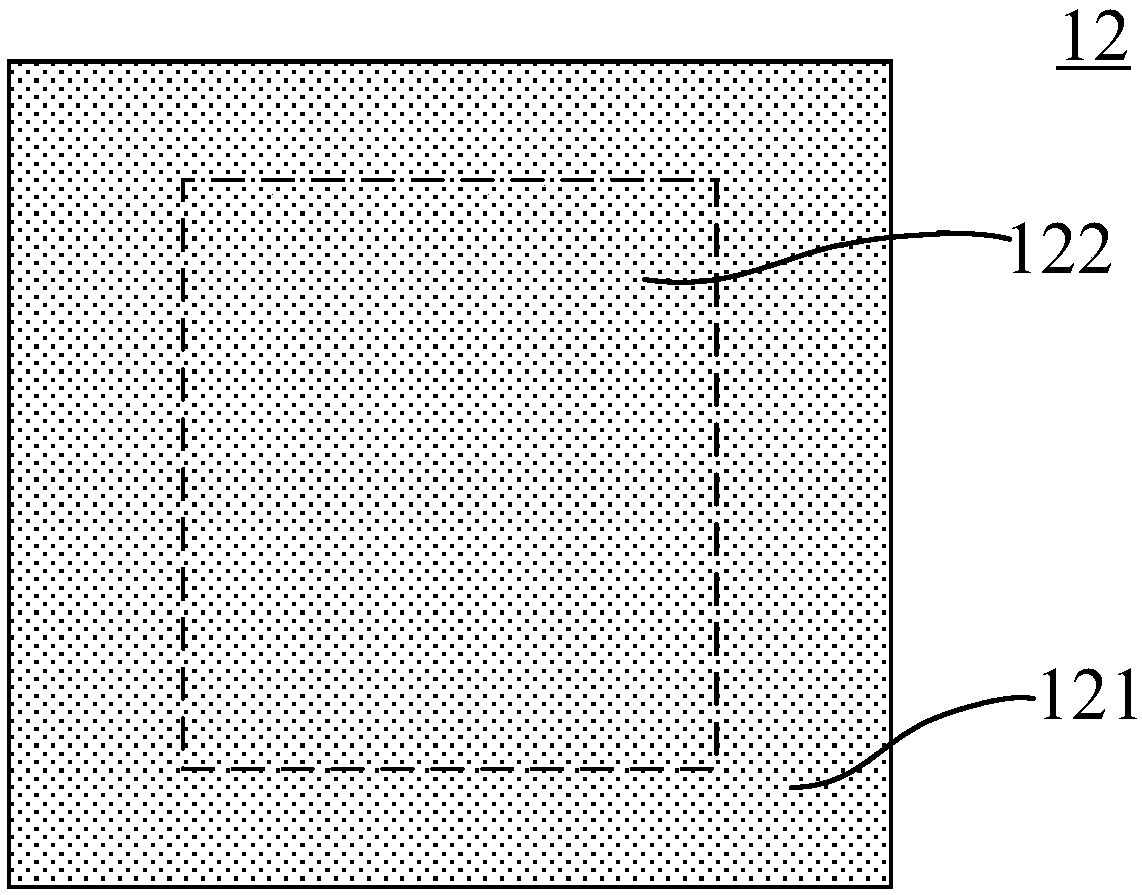

[0056] S2: Form a plurality of organic light-emitting devices 1 on one side of the base substrate 10; the organic light-emitting device 1 includes a first electrode 11, a light-emitting layer 13, and a second electrode 12 stacked along a first direction y; the first direction y is The direction perpendicular to the surface of the base substrate 10; the first electrode 11 includes a first edge electrode 111 and a first intermediate electrode 112 surrounded by the first edge electrode 111; the vertical distance between the first edge electrode 111 and the surface of the base substrate 10 D1, less than the vertical distance D2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com