Low-section all-steel radial tire with zero-degree winding belted layer

A technology of radial tires and wrapping belts, applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of tires with reduced heat dissipation performance, changes in footprints, and loss of optimal grounding performance, etc., to maintain stability and handling, good ground print effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

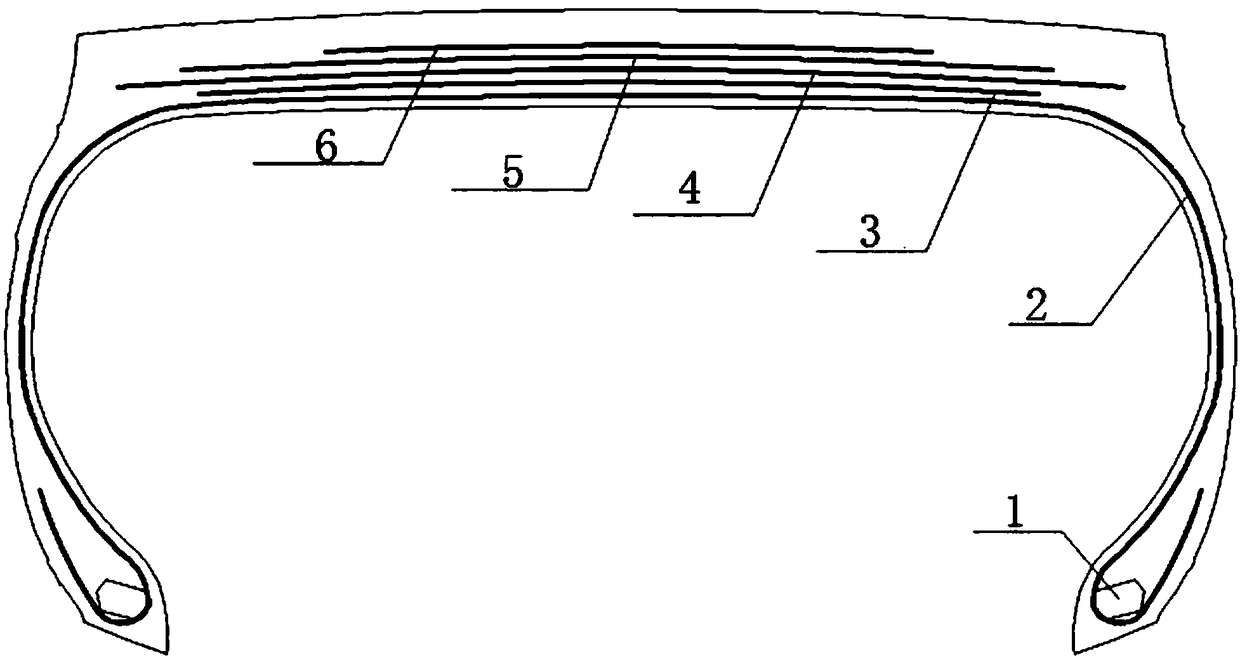

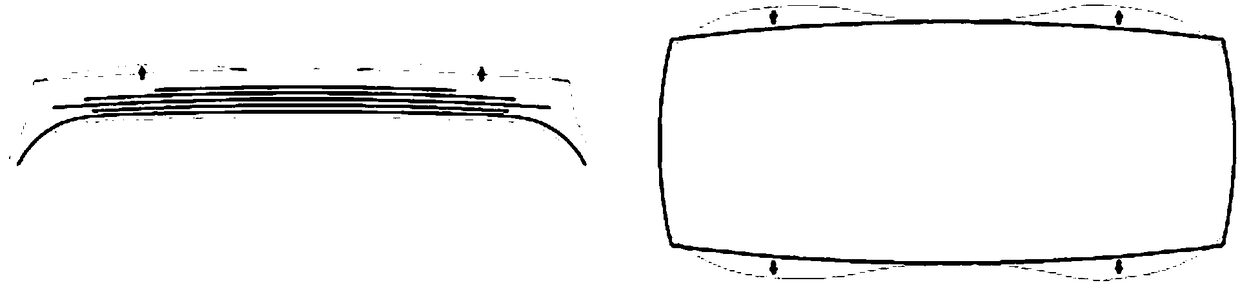

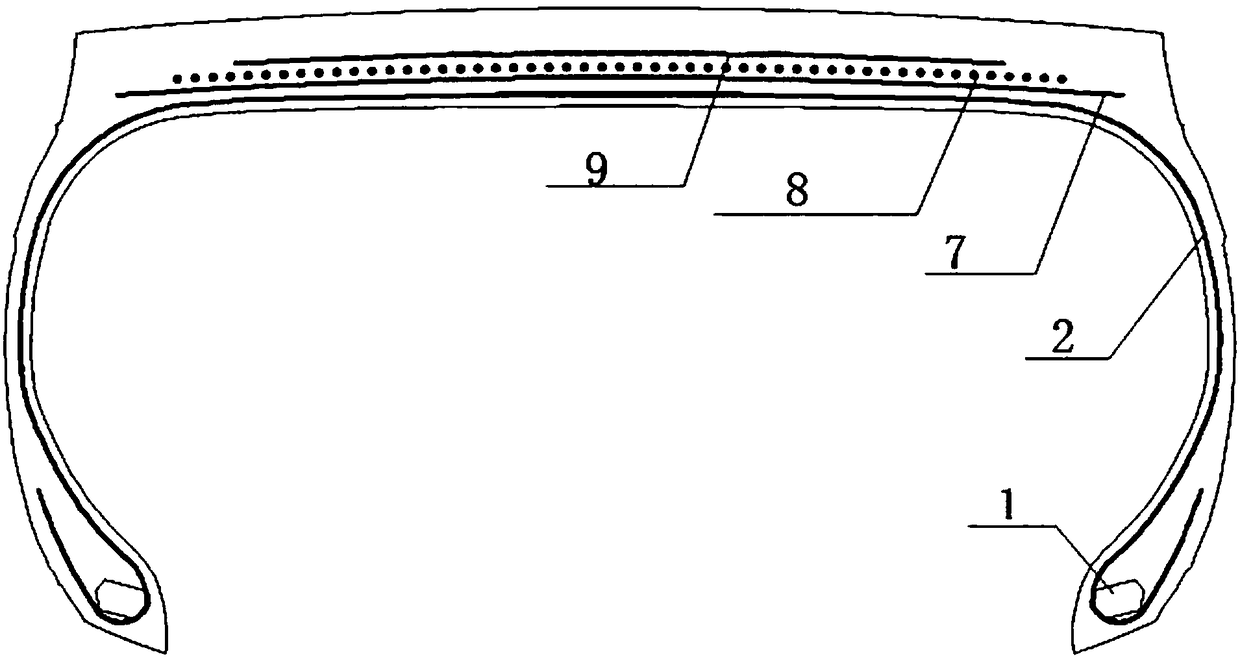

[0022] Such as image 3 , Figure 4 As shown, adopt the 295 / 55R22.5 specification tire that the present invention tries to make, the belt layer of this tire is by the first belt layer 7, 0 degree winding belt layer 8 and the second belt layer 9, the first belt layer Layer 7 and the second belt layer 9 adopt conventional belt layers, the belt angles of the first belt layer 7 and the second belt layer 9 intersect, and the first belt layer 7 and the second belt layer 9 are arranged at an angle At 18 degrees, the belt weighted angle is 34 degrees. The first belt layer 7 is arranged above the carcass 2, the 0-degree winding belt layer 8 is arranged between the first belt layer 7 and the second belt layer 9, and the second belt layer 9 is arranged on Winding on the belt layer 8 at 0 degree. The width difference between the 0-degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com