Monitoring and early-warning device for sleeve expansion joint and monitoring method thereof

A sleeve compensator and early warning device technology, applied in heating methods, central heating sensors, household heating and other directions, can solve problems such as medium leakage, reduce losses, save energy, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

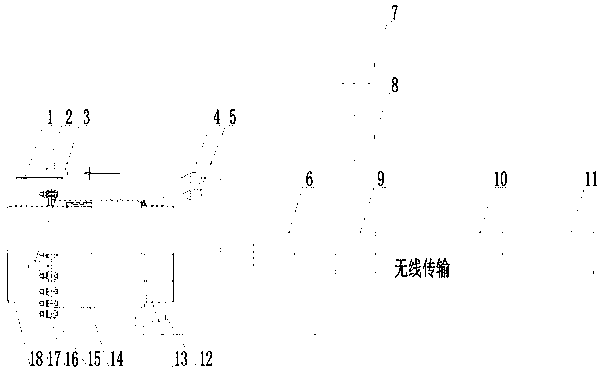

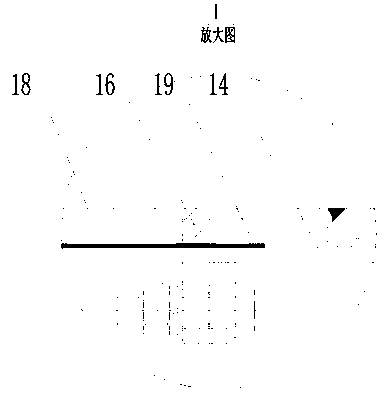

[0031] like Figure 1~5 As shown, a sleeve compensator monitoring and early warning device, a camera 12 is installed on the fixed end pipe 13, a pressure sensor 4 and a temperature sensor 5 are installed in openings, a bracket 1 is installed on the movable core tube 18 and the outer cover 14, and the bracket Install the axial displacement sensor 2 on 1; the movable core tube 18 is wrapped by the outer cover 14, and the outer cover 14 is fixedly connected with the movable core tube 18 through the anti-off flange one 15, the anti-off flange two 16 and the bolt assembly 17; on the inner surface of the outer cover 14 Lay the wire 19, one end of the wire 19 is connected to the leakage alarm sensor 3; the axial displacement sensor 2, the pressure sensor 4 and the temperature sensor 5, and the leakage alarm sensor 3 are respectively connected to the analog quantity acquisition module 6, and the analog quantity acquisition module 6 is connected to the wireless router 9 The camera 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com