Hydraulic drive for machine tool chucks

A driving device and machine tool technology, applied in fluid pressure actuating devices, fluid pressure actuating system components, mechanical equipment, etc., can solve problems such as troublesome installation, large volume, and inconvenient actual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

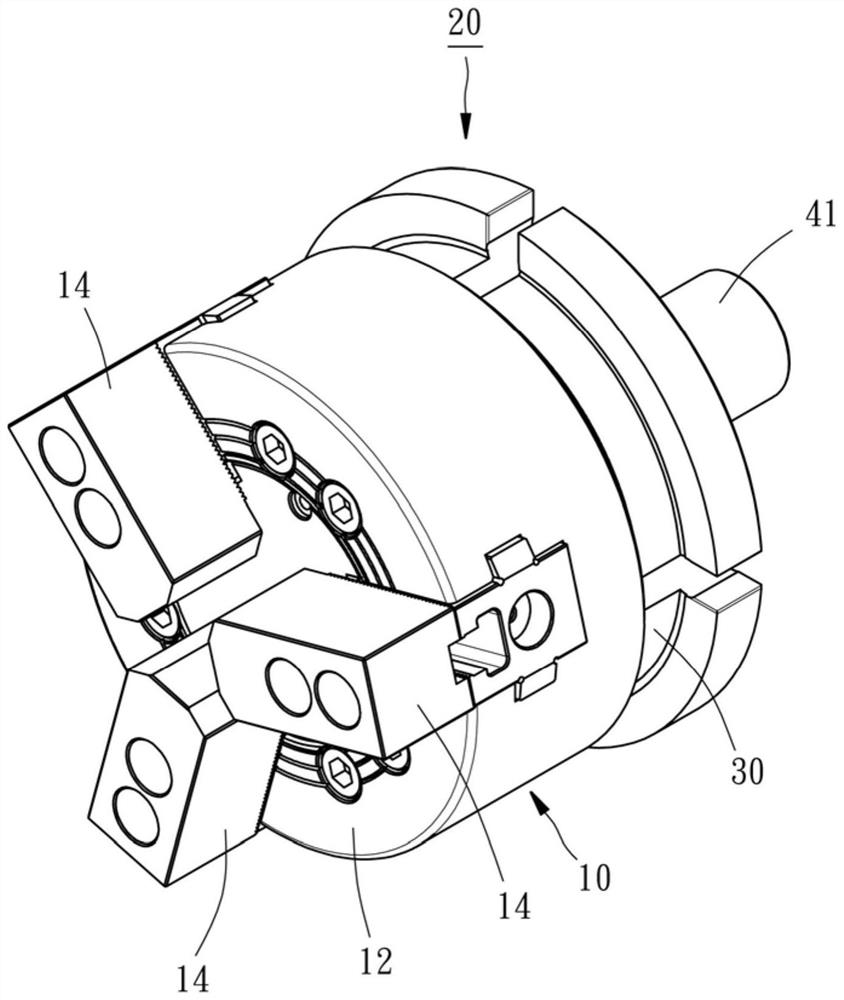

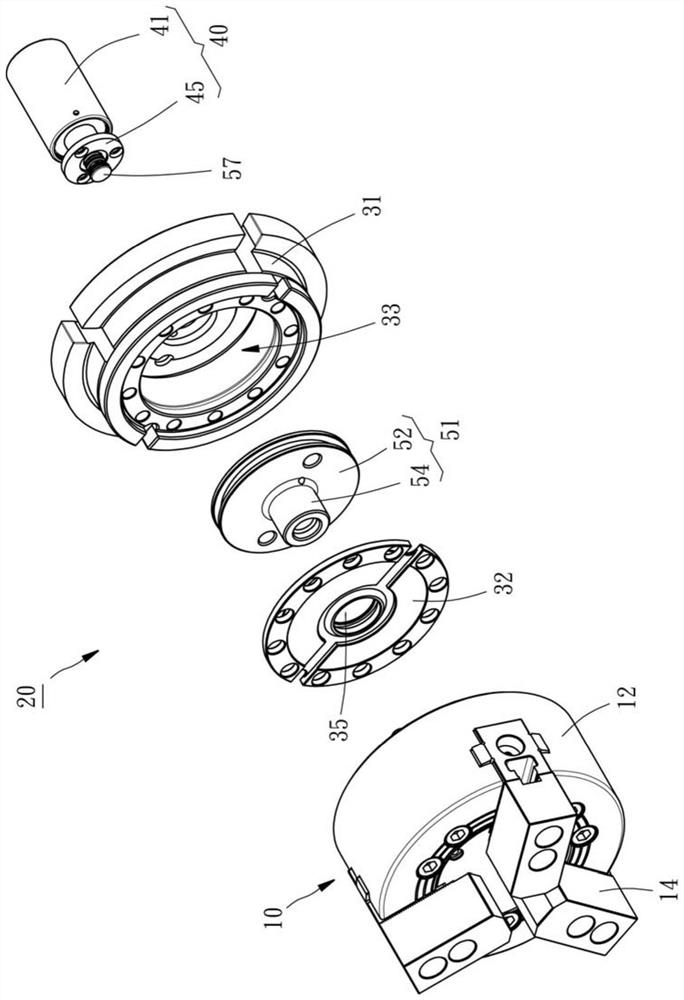

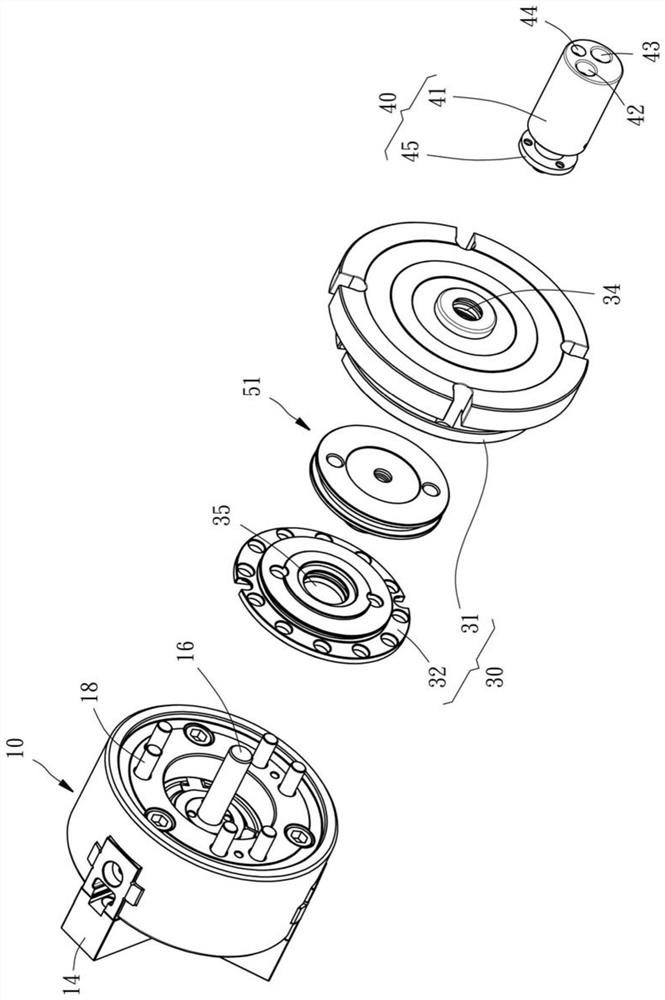

[0046] Please see first Figure 1 to Figure 3 , the collet 10 shown in the figure mainly includes a clamp seat 12 and three jaws 14, and the three jaws 14 are arranged on one end surface of the clamp seat 12 in a radial arrangement, and can be driven on the jaw drive shaft 16 Driven closer or farther away from each other, they are used to clamp or release the workpiece (not shown) to be processed. Since the chuck 10 is a known technology, in order to save space, the applicant will not repeat its detailed structure and operating principle here.

[0047] see again Figure 2 to Figure 4 , the hydraulic drive device 20 of the present invention includes a chuck connection seat 30 , an oil distribution valve 40 and a piston unit 50 .

[0048] The chuck connecting seat 30 is fixed on an end face of the clamping seat 12 facing away from each jaw 14 by a plurality of fixtures 18 (such as image 3 and Figure 4 shown). The chuck connection seat 30 has a seat body 31 and a cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com