Distribution box and its production process

A distribution box and box technology, applied in electrical components, substation/switch layout details, busbar/line layout, etc., can solve the problems of poor wiring stability, poor wire contact, and cumbersome wiring process, and achieve stable wiring. The effect of good performance, simplified wiring process and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

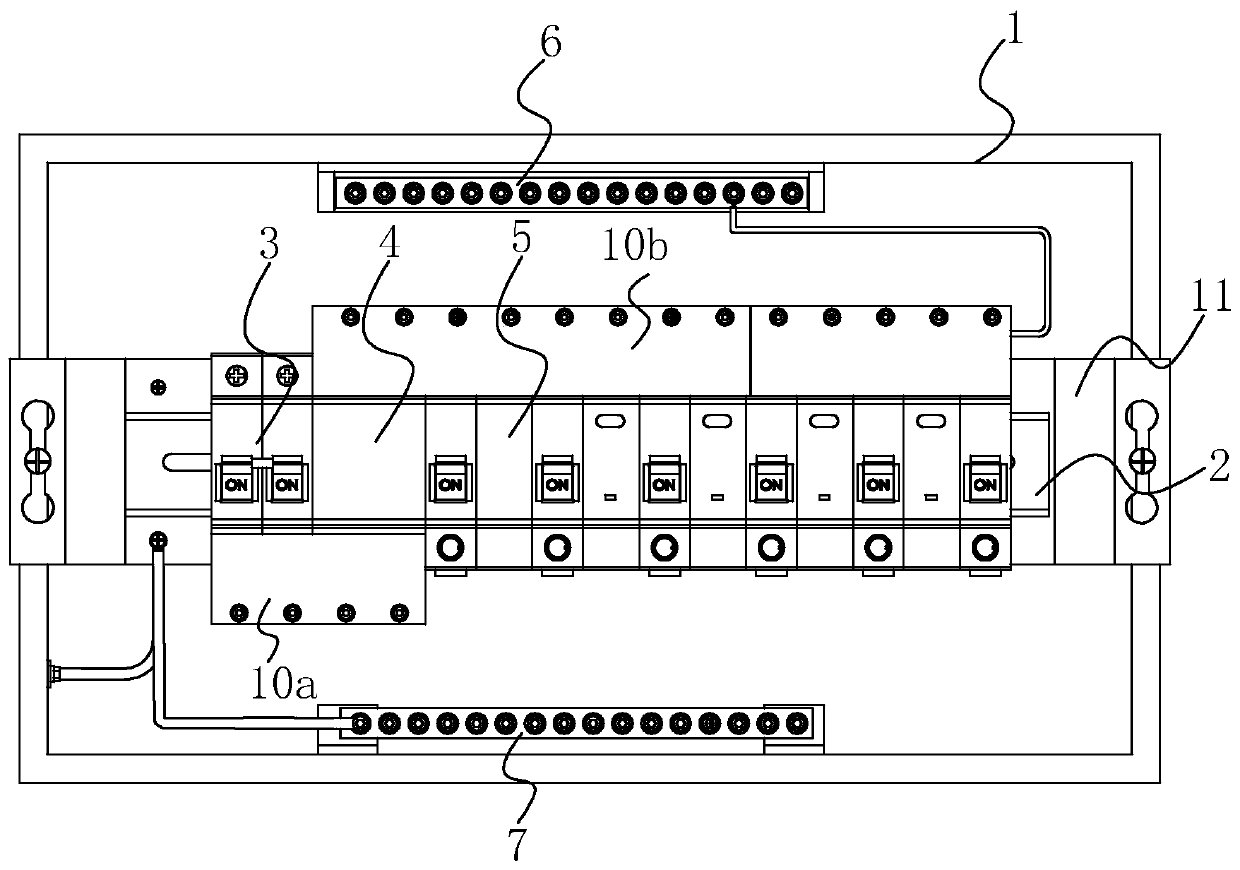

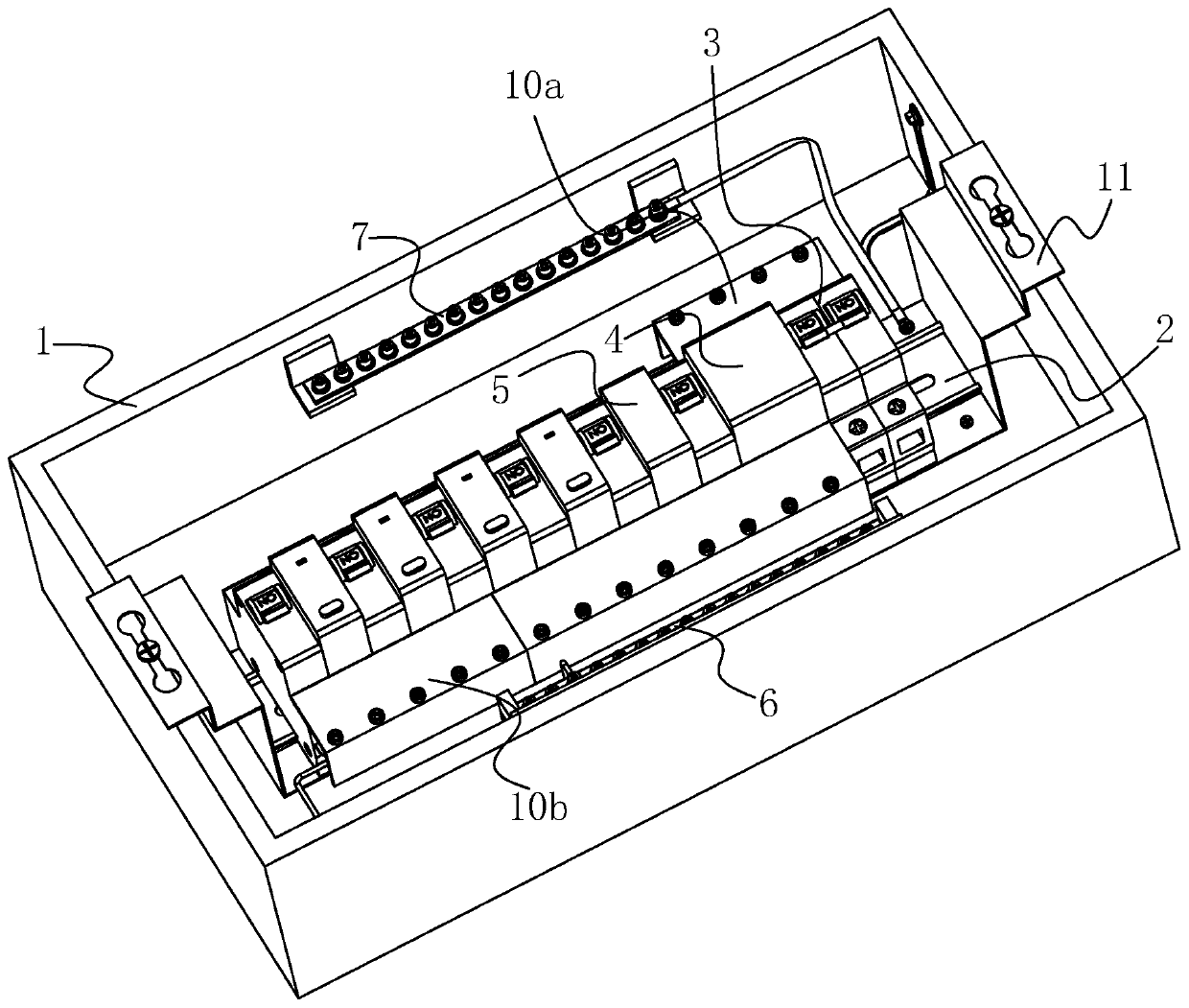

[0041] Embodiment 1: distribution box, such as figure 1 As shown, it includes a box body 1 for accommodating various components and capable of being installed on a wall. The box body 1 is a rectangular cavity with an opening on one side. A mounting seat 11 is provided inside the box body 1 , the two ends of the mounting seat 11 are fixed on two opposite side walls of the box body 1 , and the middle part is bent inward to fit the bottom wall of the box body 1 . A fixed guide rail 2 is fixed in the middle of the installation guide rail, and a switch assembly 3 , a main circuit breaker 4 and a plurality of branch circuit breakers 5 are installed side by side in sequence on the fixed guide rail 2 . A ground line bar 6 and a neutral line bar 7 are respectively fixed on both sides of the box body 1 . The ground wire bar 6 communicates with the mounting base 11 and the box body 1 through a flexible wire. The neutral line bank 7 is connected to the neutral line of the circuit breake...

Embodiment 2

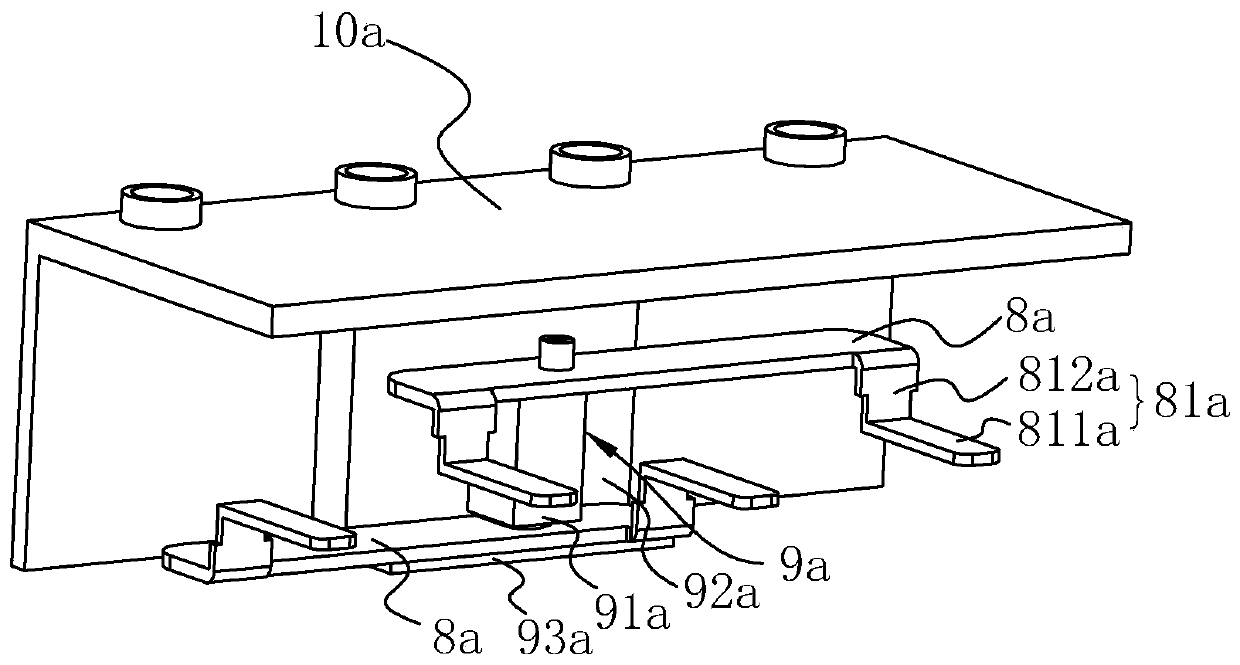

[0052] Embodiment 2: The production process of the distribution box, including the manufacturing steps of the first conductive copper bar 8a and the second conductive copper bar 8b, the manufacturing steps of the first insulating fixing part 9a and the second insulating fixing part 9b, the first electric shock prevention The manufacturing steps of the cover 10a and the second electric shock-proof cover 10b and the assembly steps of each component, wherein, the manufacturing steps of the first conductive copper bar 8a and the second conductive copper bar 8b include copper plate mold forming, punching and tributary bending .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com