An integrated detection device for compressor barrel and upper outer cover

A detection device and compressor technology, which is applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of discrete measurement points and wear of the measuring head, and achieve the effect of reducing the number of measurement stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

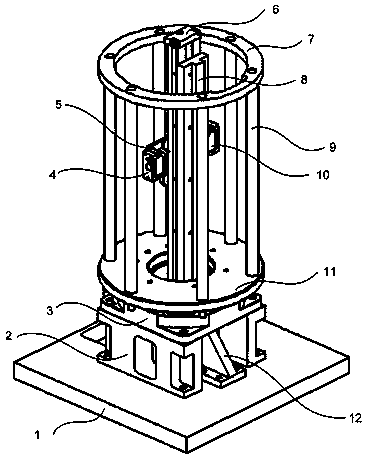

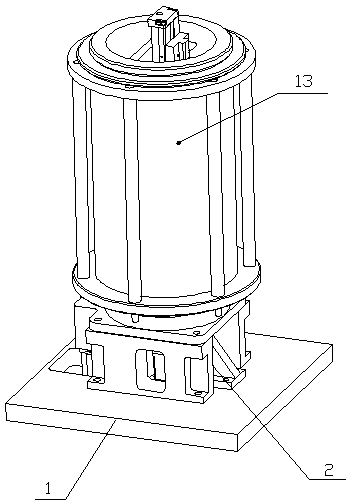

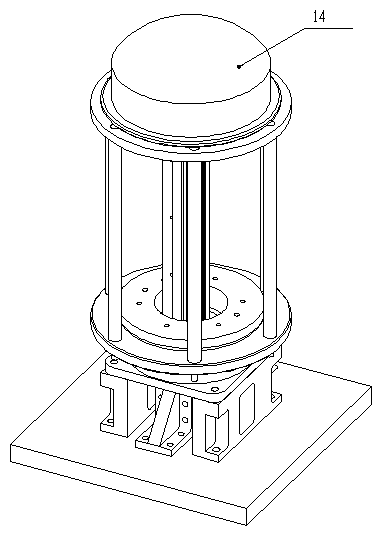

[0015] As shown in the figure, the specific implementation is as follows:

[0016] An integrated detection device for a compressor cylinder and an upper cover, comprising a bottom plate 1 and a hollow turntable support 2 installed on the bottom plate 1. The hollow turntable support 2 supports a hollow turntable 3, the hollow turntable 3 A cylinder support plate 11 for supporting the cylinder to be tested is fixedly installed on the upper surface. The cylinder support plate 11 is driven to rotate through the hollow turntable to drive the cylinder supported on the cylinder support plate to rotate. The upper surface of the cylinder support plate 11 A number of uprights 9 are evenly distributed. The uprights 9 support an upper cover support plate 7 for supporting the upper cover to be tested. The center line of the cylinder supported on the cylinder support plate 11 and the upper cover supported on the upper cover support plate 7 The center lines coincide. The bottom plate 1 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com