Module with printed circuit board

A printed circuit board and conductive connection technology, applied in the field of modular products, can solve problems such as unfavorable assembly experience for consumers, unfavorable product internal structure storage function, and unfavorable production line workers mass production, etc., to improve convenience. , optimize the wire layout, improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

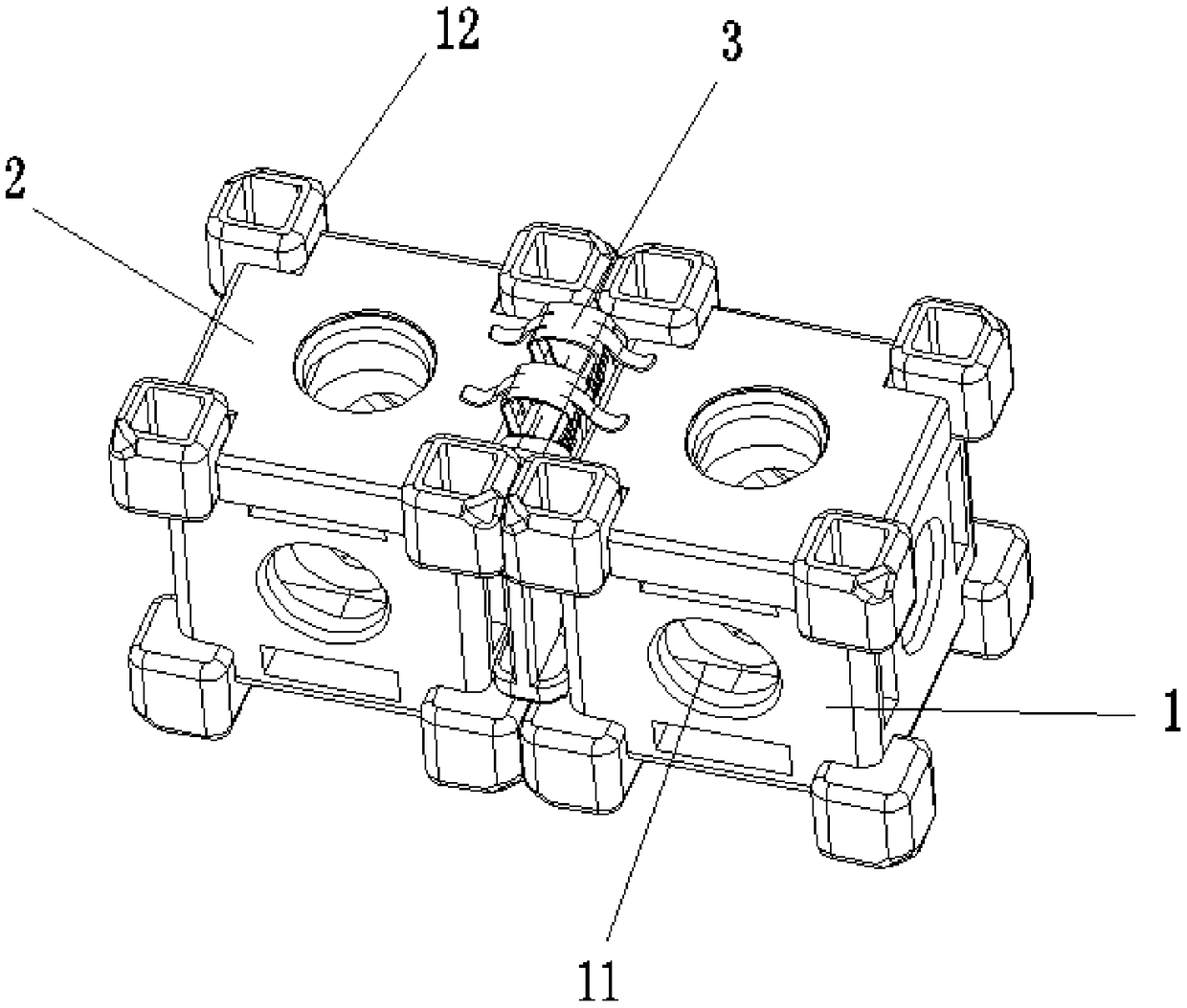

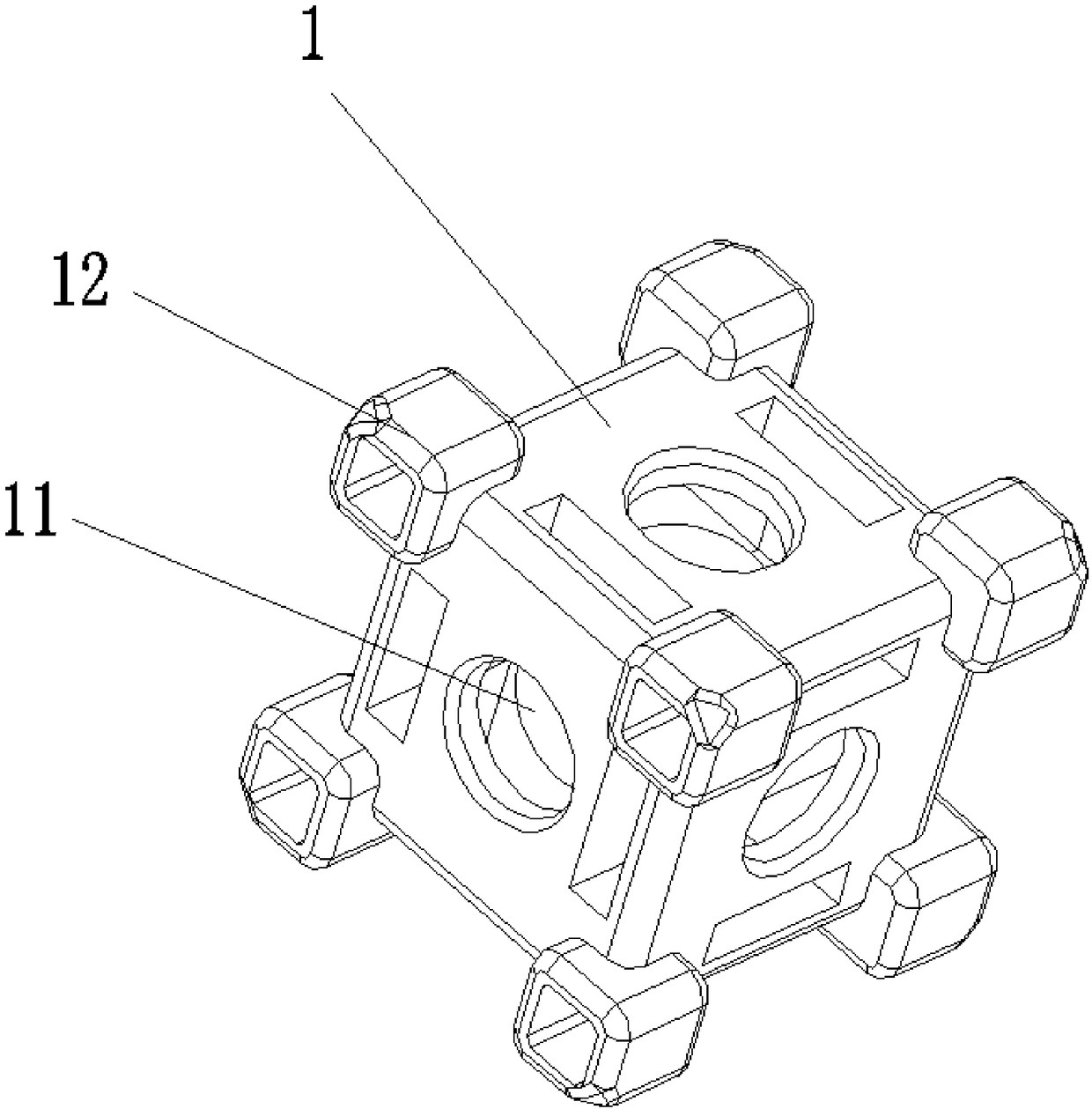

[0039] like Figure 1-Figure 10 As shown, the embodiment of the present invention provides a module with a printed circuit board, including a module body 1, a printed circuit board 2 and a conductive connector 3;

[0040] The module body 1 has a regular hexahedral structure, and the middle part of each surface is provided with a first through hole 11; each corner is provided with a regular hexahedral protrusion 12, and the regular hexahedral protrusion 12 and the side surface of the module body 11 form a ten-dimensional structure. glyph inner groove;

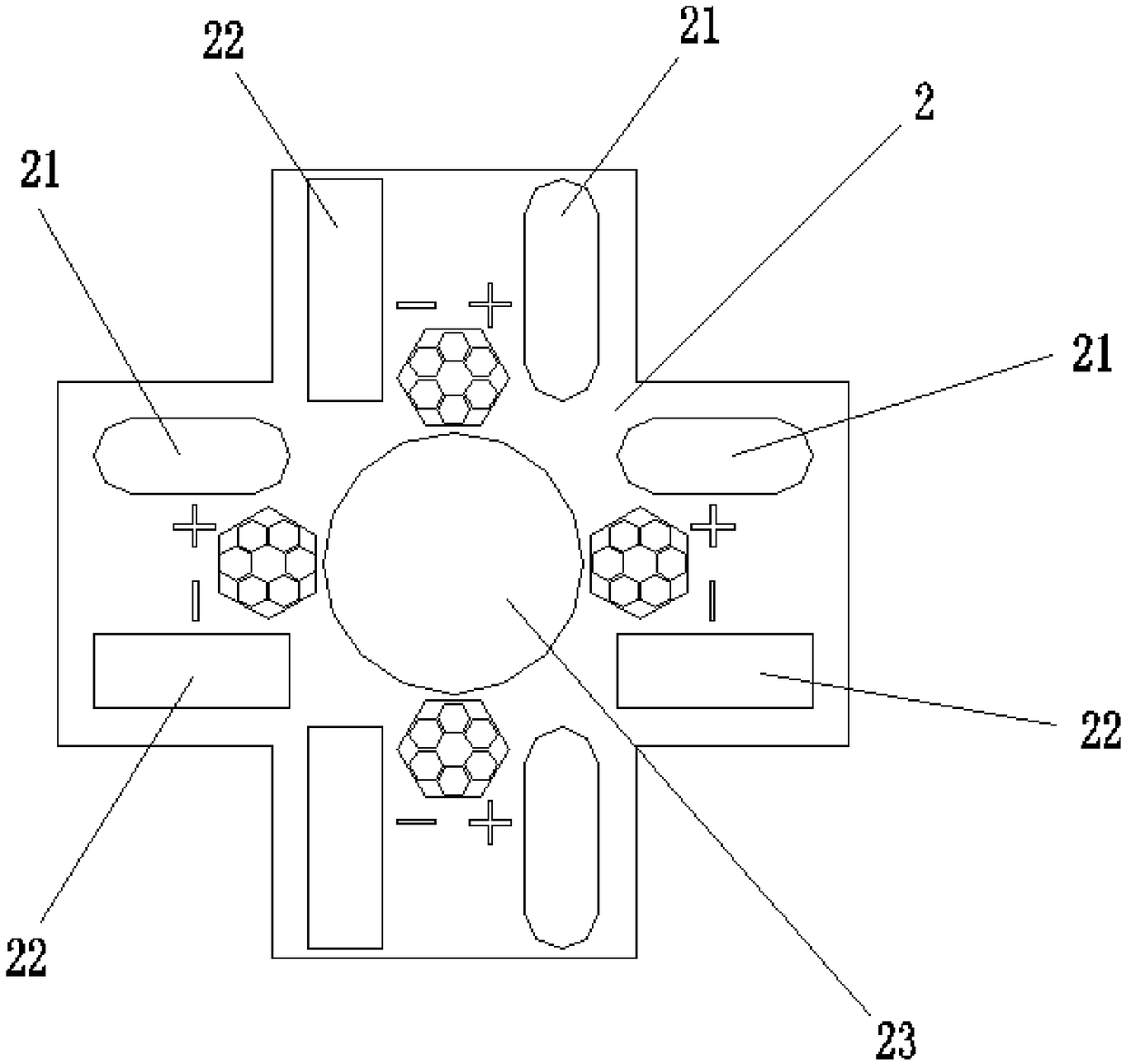

[0041] The printed circuit board 2 is a circuit board whose structure matches the cross-shaped inner groove, and the printed circuit board 2 is provided with a positive electrode connection terminal 21 and a negative electrode at the end positions along the four directions of the cross-shaped inner groove. Connecting end 22; all positive connecting ends 21 are electrically connected to each other, and all negative connecting en...

Embodiment 2

[0051] like figure 2 , Figure 10-Figure 16 As shown, the difference between the embodiment of the present invention and embodiment 1 is that the embodiment of the present invention includes not only the module body 1 and the printed circuit board 2, but also includes a decorative sheet 5 and a puncture elastic sheet 6; wherein, the decorative sheet 5 The back side is provided with buckle and piercing shrapnel mount 51, and the bottom of piercing shrapnel 6 snaps into the piercing shrapnel mount 51; the second through hole 23 in the middle of the printed circuit board 2 can pass through the decorative plate In the installed state, the printed circuit board 2 is arranged between the decorative sheet 5 and the module body 1, the positive ports 21 of adjacent printed circuit boards 2 overlap each other, and the negative ports 22 overlap each other The decorative sheet 5 is clamped on the module body 1, and the piercing elastic sheet 6 pierces the overlapped positive port 21 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com