Method and apparatuse for supporting forming bodies of glass forming apparatuses

一种成形设备、主体的技术,应用在玻璃的成型、玻璃的成型、玻璃制造设备等方向,能够解决熔合工艺中断、玻璃带特性下降、机械性能下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

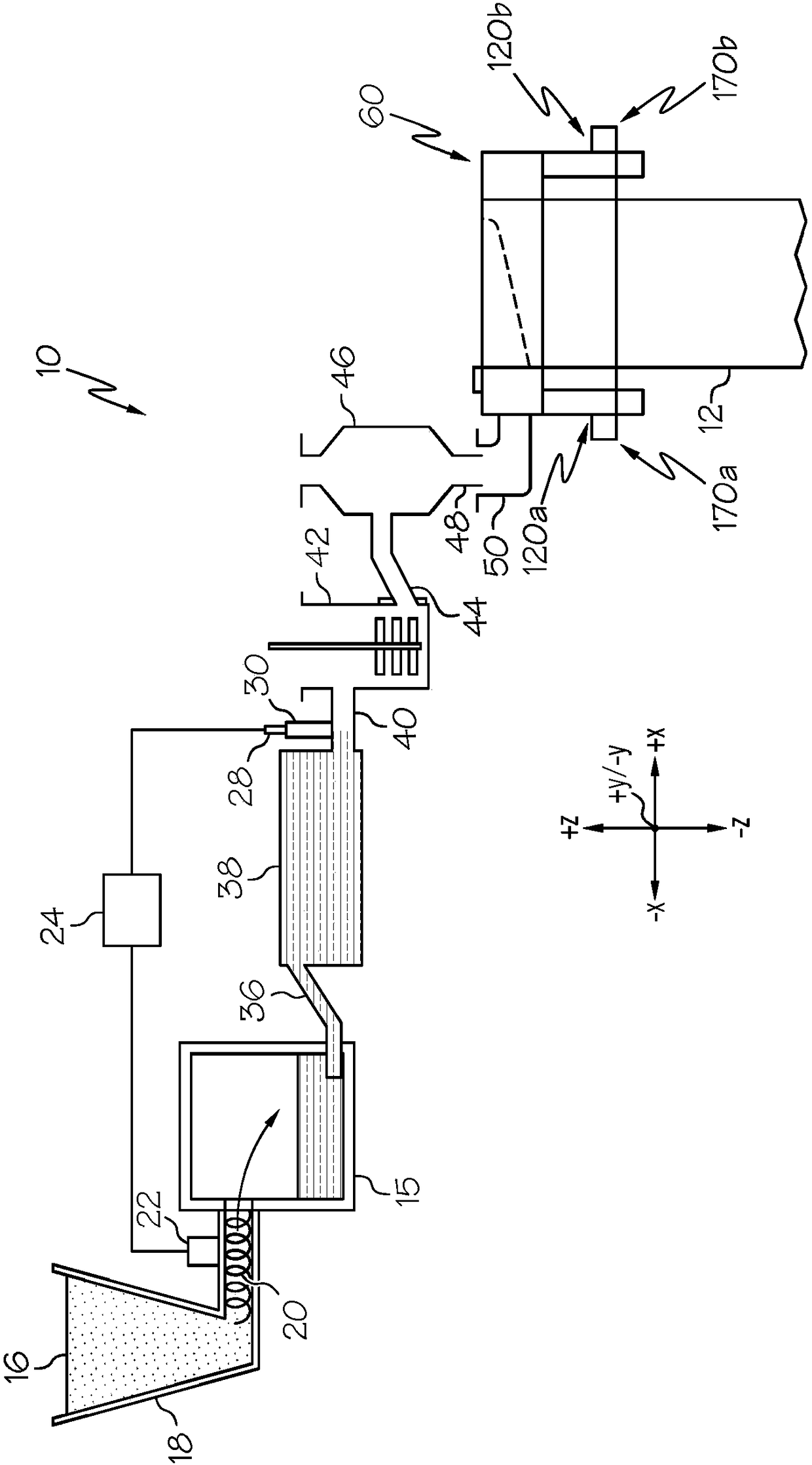

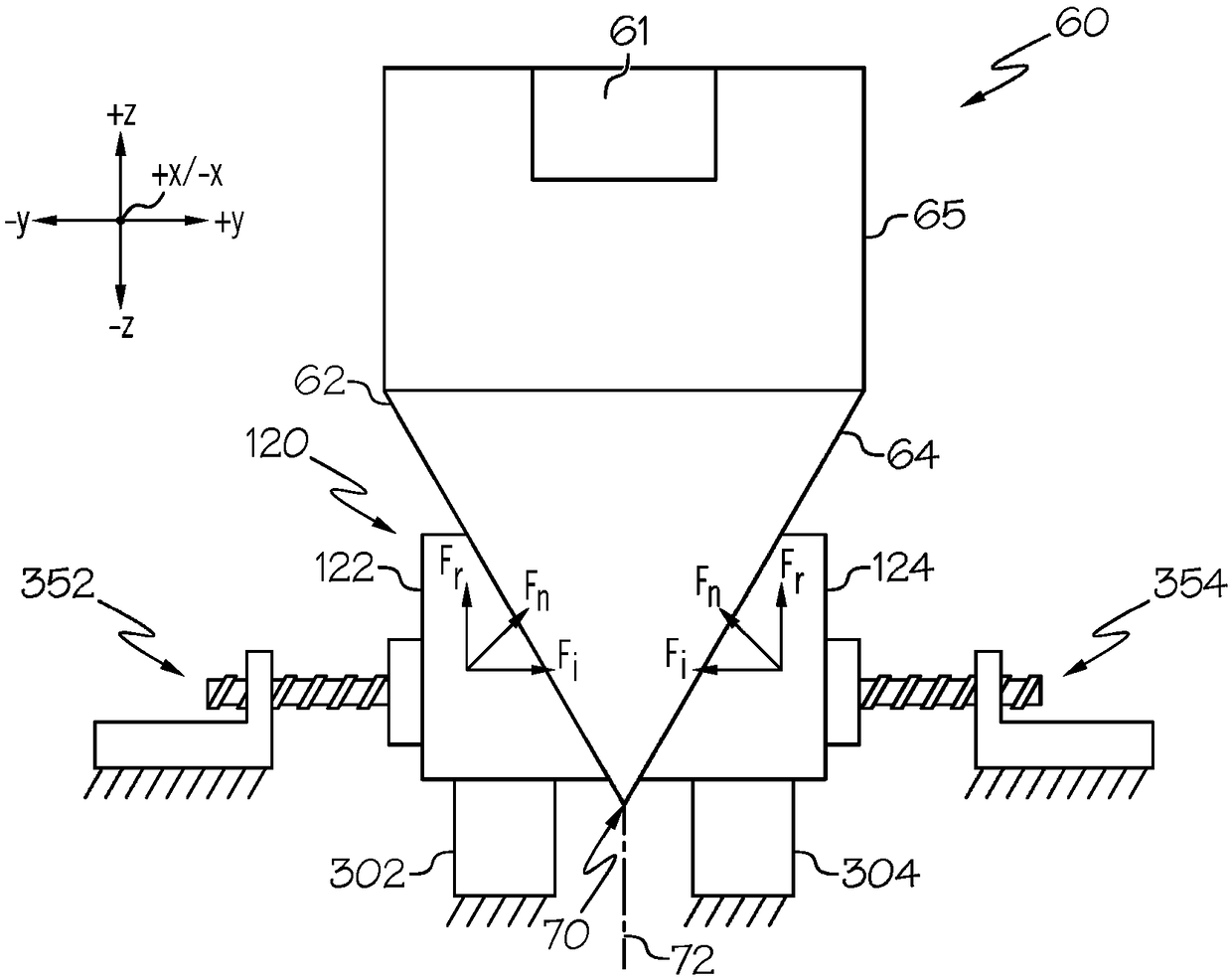

[0069] Form the mathematical model of the forming body under three independent support conditions, and the three independent supporting conditions are: (1) conventionally, the forming body is supported by piers at any end, as shown in Figure 7, while The compressive force applied was 9000 lbs. (4082.3 kg-F); (2) the forming body was supported by a bracket assembly (two bracket block configuration) that contacted the forming body at either end of the forming body The forming surface, and the end block applies a compressive force of 9000lbs. (4082.3kg-F) to the end surface of the forming body, such as figure 2 and (3) supporting the forming body with a bracket assembly (two bracket block configuration) that contacts the forming surface of the forming body at either end of the forming body, with the end blocks facing toward the forming body A compressive force of 8000lbs. (3628.7kg-F) is applied to the end face, such as figure 2 shown. The modeled forming body was based on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com