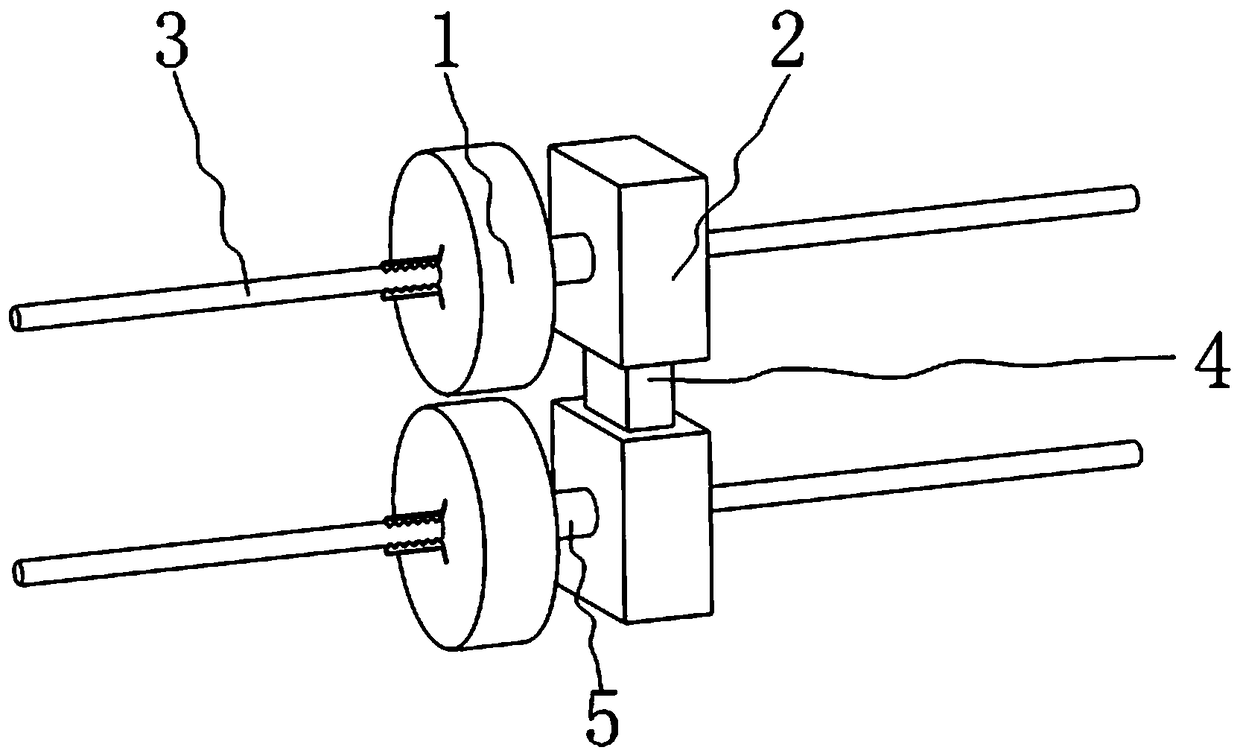

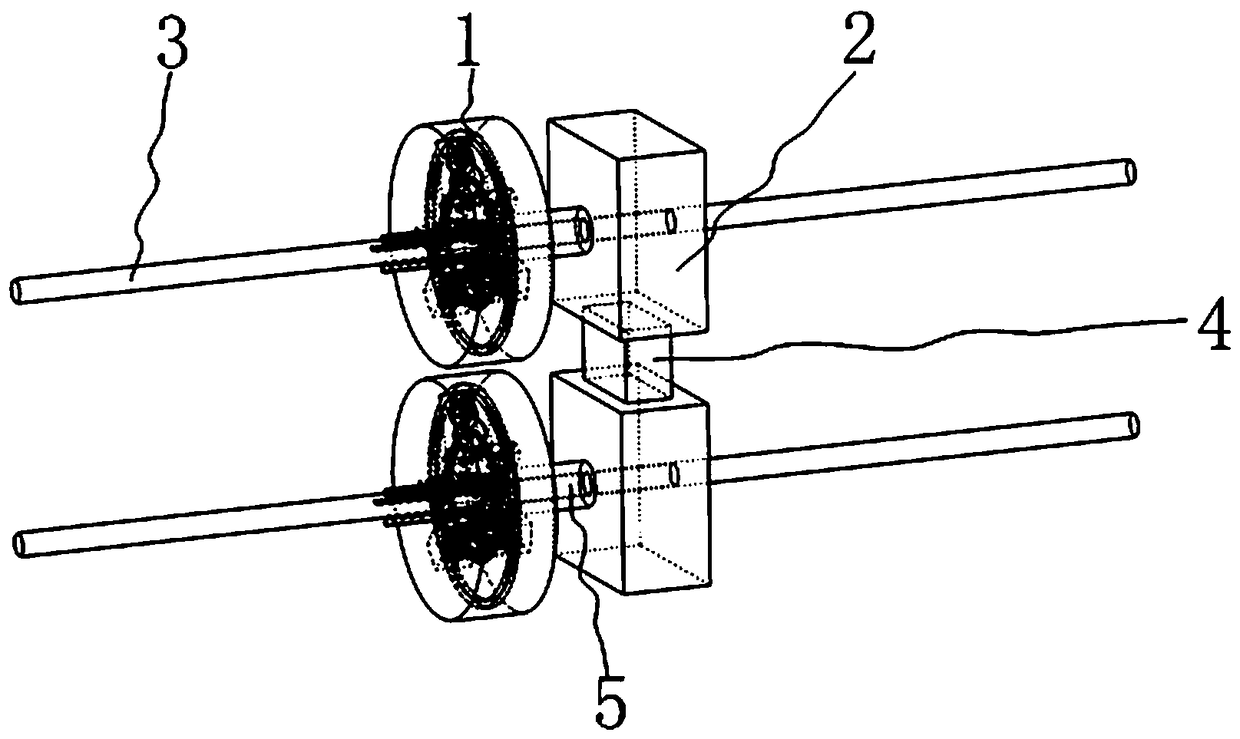

Electric wire deicing device

A wire and battery technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of system safety impact, high cost, and threat to the safe and stable operation of the power grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

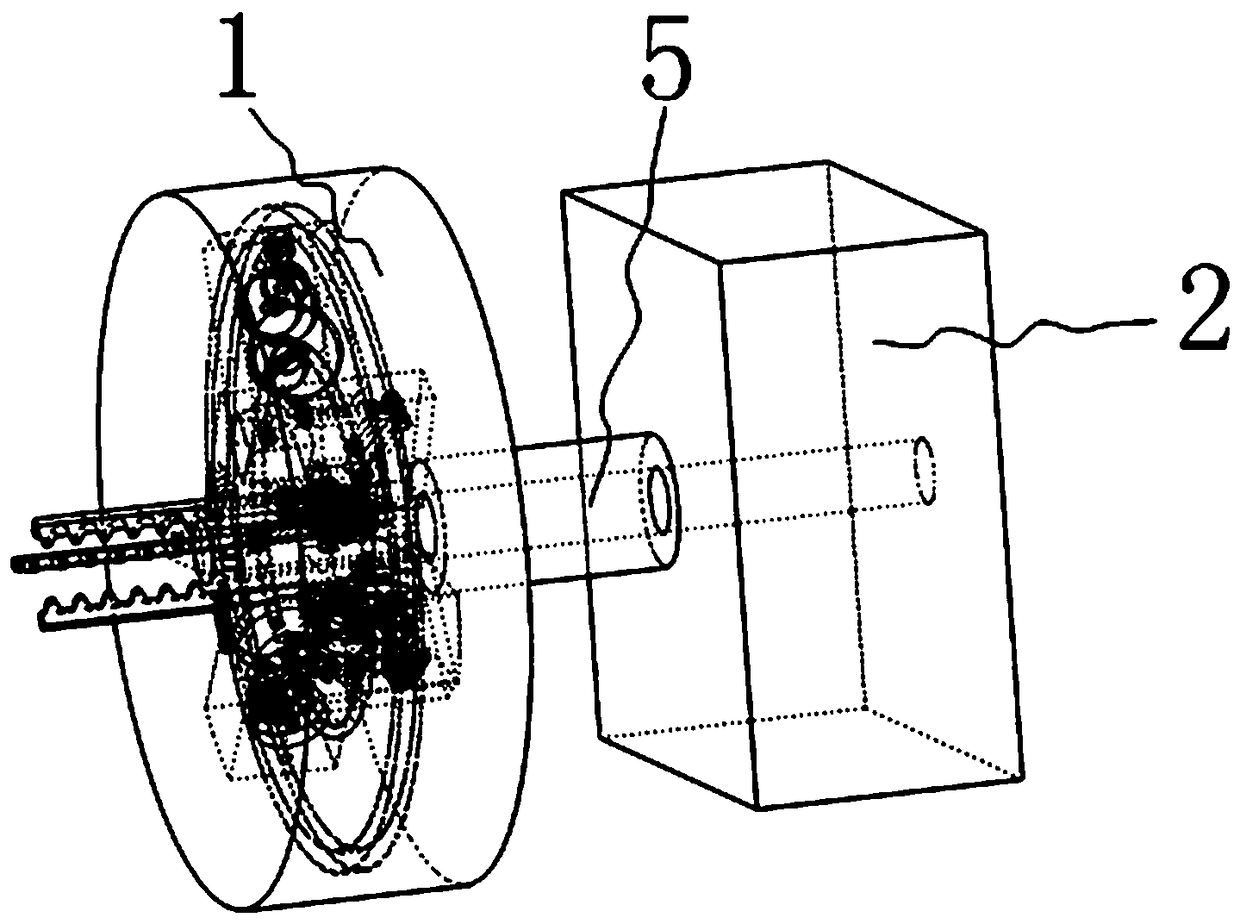

[0061] The specific embodiment: when using the electric wire 3 deicing device designed by the present invention, the electric wire 3 deicing device is placed on two adjacent electric wires 3 up and down; two running gears 2 are controlled so that the two running gears 2 are Drive the two deicing mechanisms 1 to move forward through the corresponding rotating shaft sleeve 5, and at the same time make the two deicing mechanisms 1 rotate around the corresponding electric wires 3; at the same time control the work of the driving motor 18 in the deicing mechanism 1 to drive The motor 18 will drive the corresponding second gear 20 to rotate; the second gear 20 will drive the corresponding first gear 19 to rotate; the rotation of the first gear 19 will drive the corresponding flexible shaft 21 to rotate; under normal conditions, the rotation of the flexible shaft 21 will drive the corresponding The first adjustment shaft 53, the second adjustment shaft 67 and the third adjustment shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com